Method for profile control and oil displacement by immobilizing microorganisms

A microbial immobilization and microbial technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of short microbial retention time, failure to reach clogged formations, low oil recovery rate, etc., and achieve improved Oil recovery, high oil displacement effect, and long retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

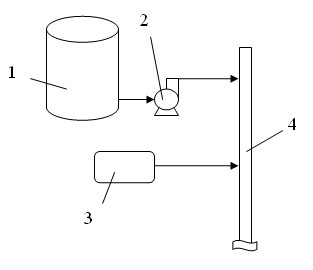

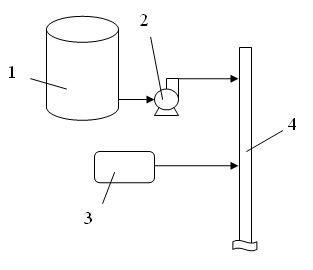

[0028] Refer to attached figure 1 .

[0029] A method for microbial immobilization profile control and oil displacement. Microorganisms are injected into oil wells for profile control and oil displacement. The microorganisms are immobilized before being injected into oil wells. The immobilization process includes:

[0030] 1. Preparation of bacterial suspension: Use the beneficial microorganisms screened in the oil field to provide the necessary nutrient source for the microorganisms in the fermenter of the ground factory, so that the microorganisms can proliferate, and the concentration of the microorganisms reaches 10 6 more than one / ml. Beneficial microorganisms are bacteria that can produce surfactants, emulsifiers, viscous polymers, gas production, etc. in the formation environment, which are beneficial to improving the properties of crude oil. The types of beneficial microorganisms mainly include: one or more of fermentation bacteria, hydrocarbon degrading bacteria, ac...

Embodiment 2

[0035] As in Example 1. Wherein, when preparing the bacterial suspension, a 1.5% sodium alginate solution was prepared and filtered with a 0.22 μm microporous membrane under pressure. Preparation of microcapsules: use a microcapsule instrument to spray the suspension into 8% calcium isooctanoate solution by adjusting the size of the nozzle, controlling the flow rate and other process parameters, and let it stand for calcification for 4 hours to obtain a diameter in the range of 40μm-80μm microcapsules inside. Wash the microcapsules with deionized water.

[0036] The role of microbial microcapsules in enhancing oil recovery is as follows:

[0037] which performed

[0038] In this example, the microcapsules encapsulating microorganisms do not affect the migration of bacterial nutrition and beneficial metabolites, and the microorganisms in the microcapsules can prolong the action time in the bottom layer, which can improve the fluidity of crude oil; adjust the water f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com