Lithium ion battery negative slurry and lithium ion battery

A lithium-ion battery, negative electrode slurry technology, applied in battery electrodes, secondary batteries, active material electrodes, etc., can solve the problems of poor battery performance consistency, poor battery quality consistency, poor storage stability, etc. The effect of improving stability, normal temperature cycle performance and high temperature cycle performance, and stable storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

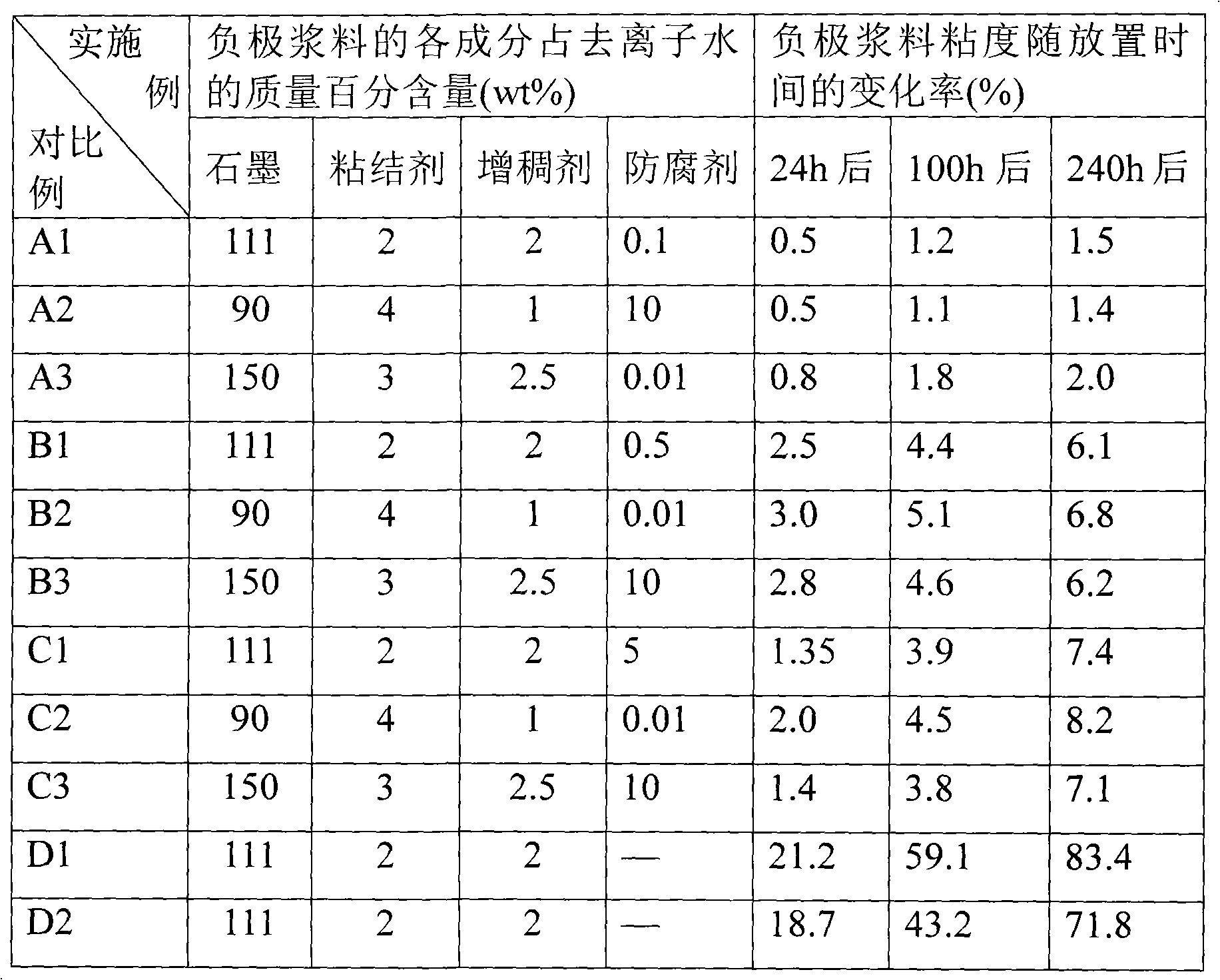

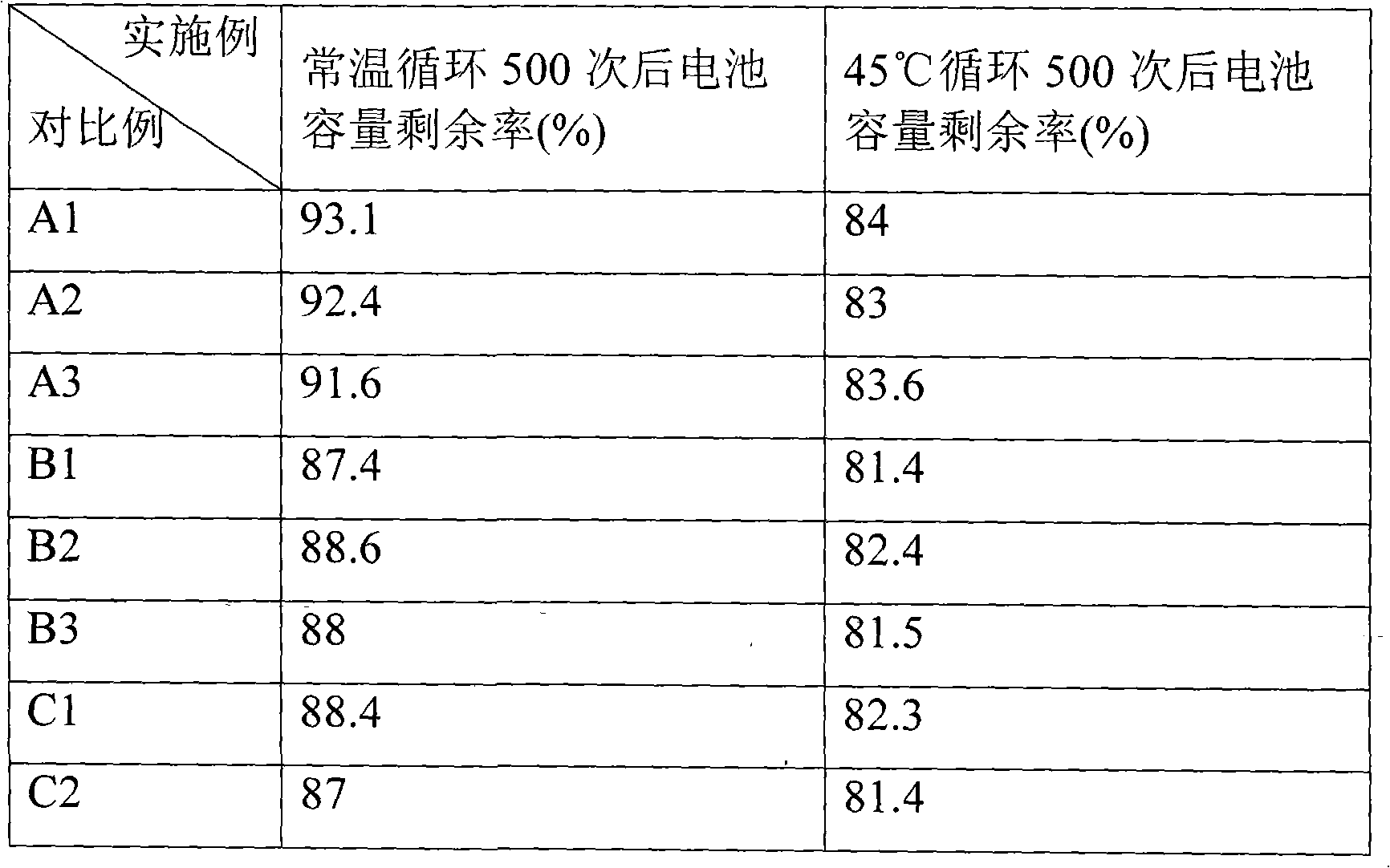

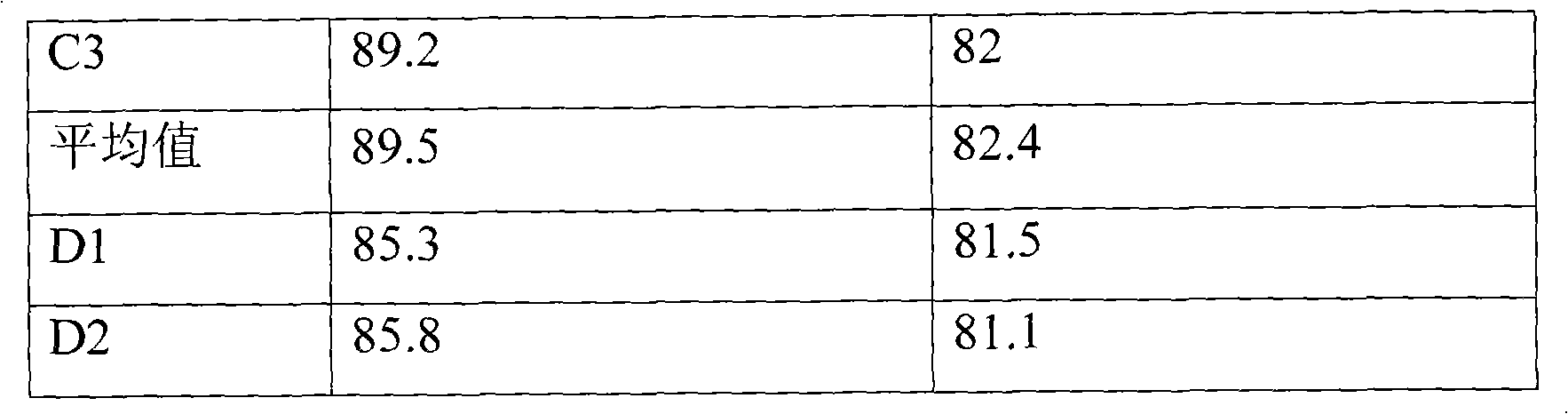

Embodiment 1

[0019] 1. Preparation of negative electrode sheet for lithium ion battery:

[0020] 5,000 grams of artificial graphite, 90 grams of CMC with a weight-average molecular weight of 400,000, 90 grams of SBR, 4,500 grams of deionized water, and 4.5 grams of phenol were mixed and stirred to obtain a negative electrode slurry A1.

[0021] The negative electrode slurry A1 obtained in the previous step was coated on a copper foil with a thickness of 8um with a slurry machine, dried at 90°C, pressed into sheets, and then cut into negative sheets with a length×width×thickness=479mm×43.5mm×0.13mm , each negative sheet contains 2.95 grams of artificial graphite.

[0022] Preparation of positive electrode sheet for lithium ion battery: 5000 grams of lithium cobalt oxide, 75 grams of PVDF binder with a weight average molecular weight of 700,000, 150 grams of conductive agent carbon powder, 1500 grams of NMP, mixed and stirred to obtain a positive electrode slurry.

[0023] 2. Coat the posit...

Embodiment 2

[0026] 5000 grams of artificial graphite, 90 grams of CMC with a weight average molecular weight of 400,000, 90 grams of SBR, 4500 grams of deionized water, and 450 grams of phenol are mixed and stirred evenly to obtain negative electrode slurry A2. Others are the same as in Example 1.

Embodiment 3

[0028] 5000 grams of artificial graphite, 90 grams of CMC with a weight-average molecular weight of 400,000, 90 grams of SBR, 4500 grams of deionized water, and 0.45 grams of phenol were mixed and stirred to obtain a negative electrode slurry A3. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com