Gypsum-based gel material pouring method and device

A technology of gel material and pouring method, which is applied to ceramic molding machines, manufacturing tools, etc., can solve problems such as loss of meaning, prolonged final setting time of slurry, and difficulty in realizing multiple groups of continuous pouring, so as to reduce labor intensity and be operable Excellent performance, enhance the internal and external quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] The invention relates to a pouring method of a gypsum-based gel material, which comprises pouring the batched gypsum-based gel material into a forming mold through a piston pump.

[0017] The volume of the pump cavity is consistent with the cavity volume of the molding die, that is, the amount of pouring each time is consistent with the required amount of the molding die.

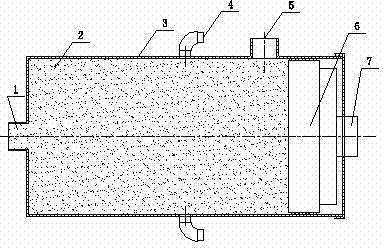

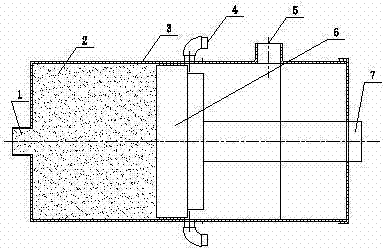

[0018] Depend on figure 1 , figure 2 It can be seen that a gypsum-based gel material pouring device for realizing the above method includes a cylinder body 3, a piston 6, a feed valve and a discharge valve, and the cylinder body 3 is provided with a feed port 5 and a feed valve controlled by the feed valve. Controlled by the discharge valve and discharge port 1.

[0019] In order to ensure pouring quality in the present invention, the cylinder body 3 is provided with a cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com