Spiral compound post

A composite and column technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of difficulty in popularization, consumption of a lot of natural resources and energy, multiple steel or concrete, etc., and achieve short construction period, technical significance and obvious social benefits , the effect of low comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following embodiments.

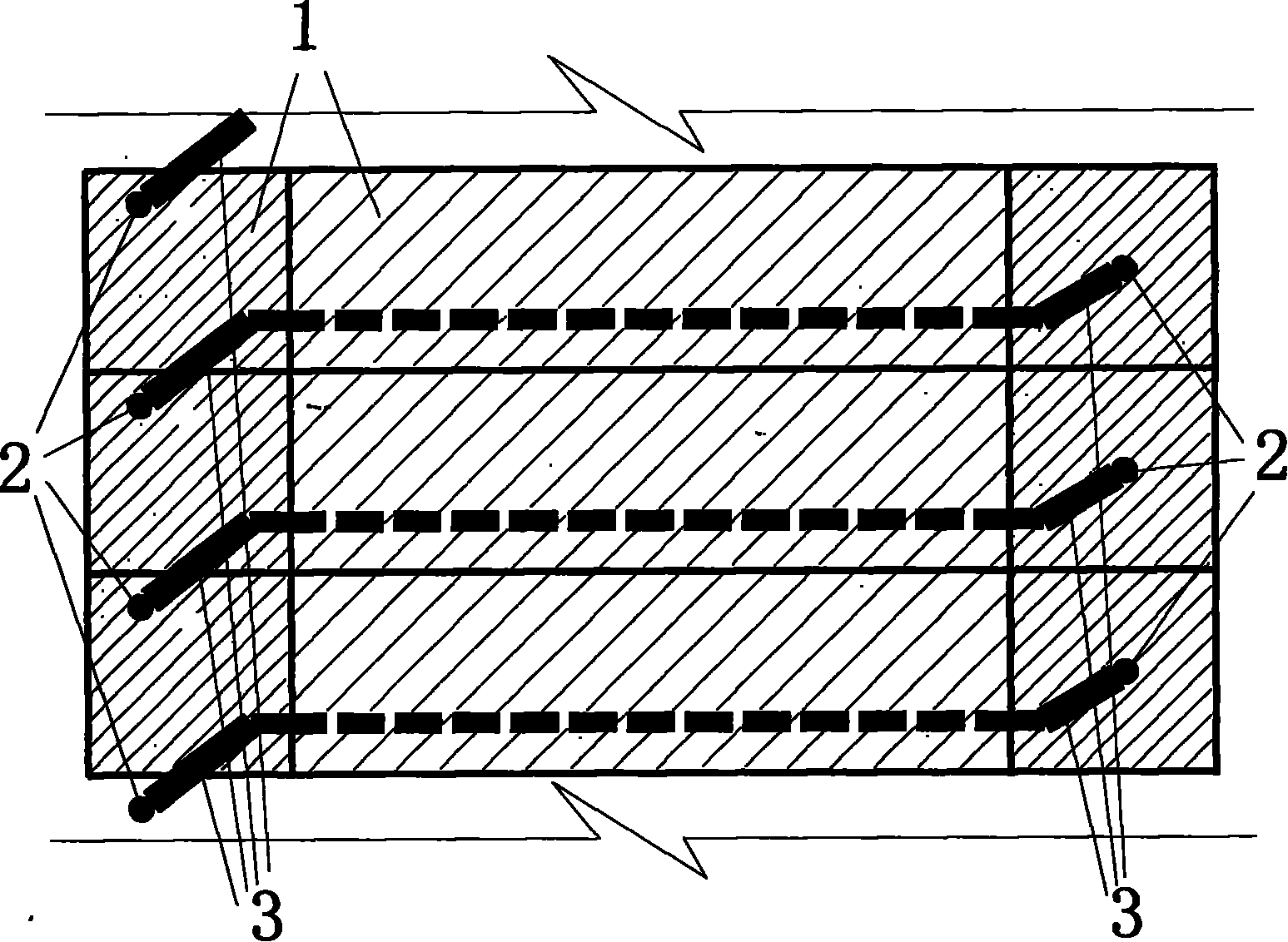

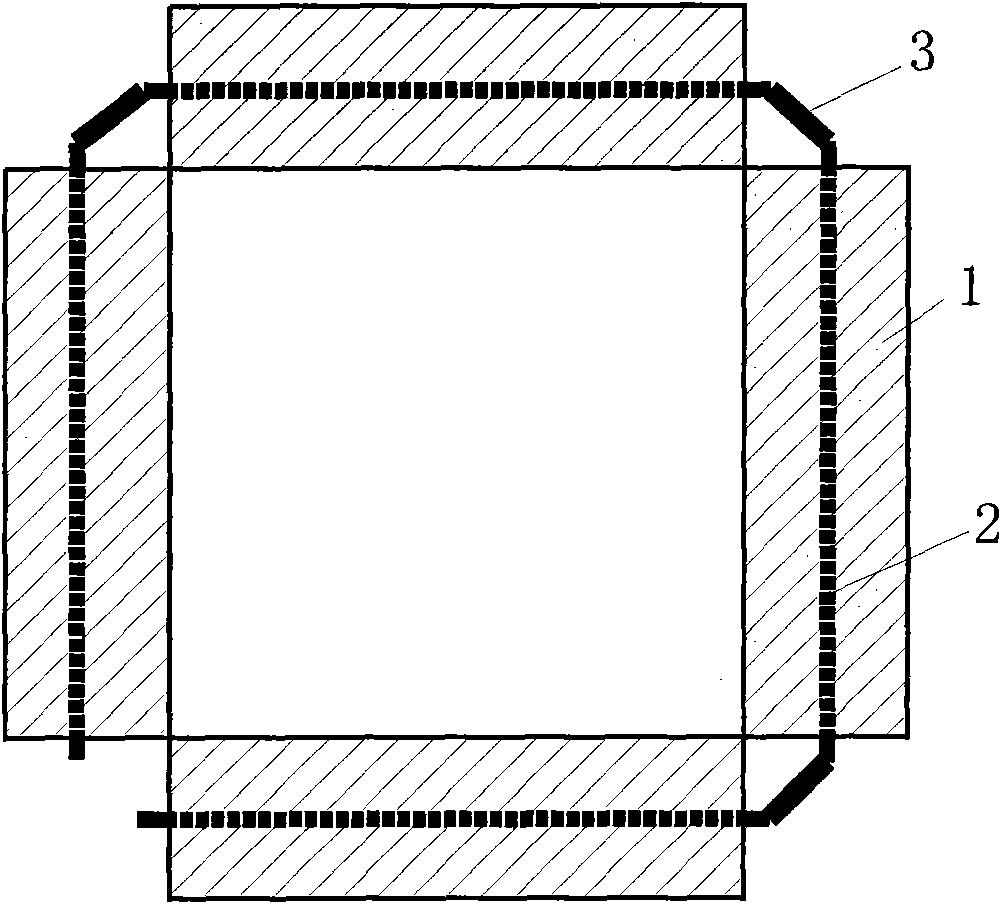

[0019] First, select the appropriate size and material of the block 1 according to the stress condition of the column, and divide it into four types according to the relative height of the embedded steel bar 2 inside each block 1, which are recorded as A, B, C, and D (according to the height by low to high order).

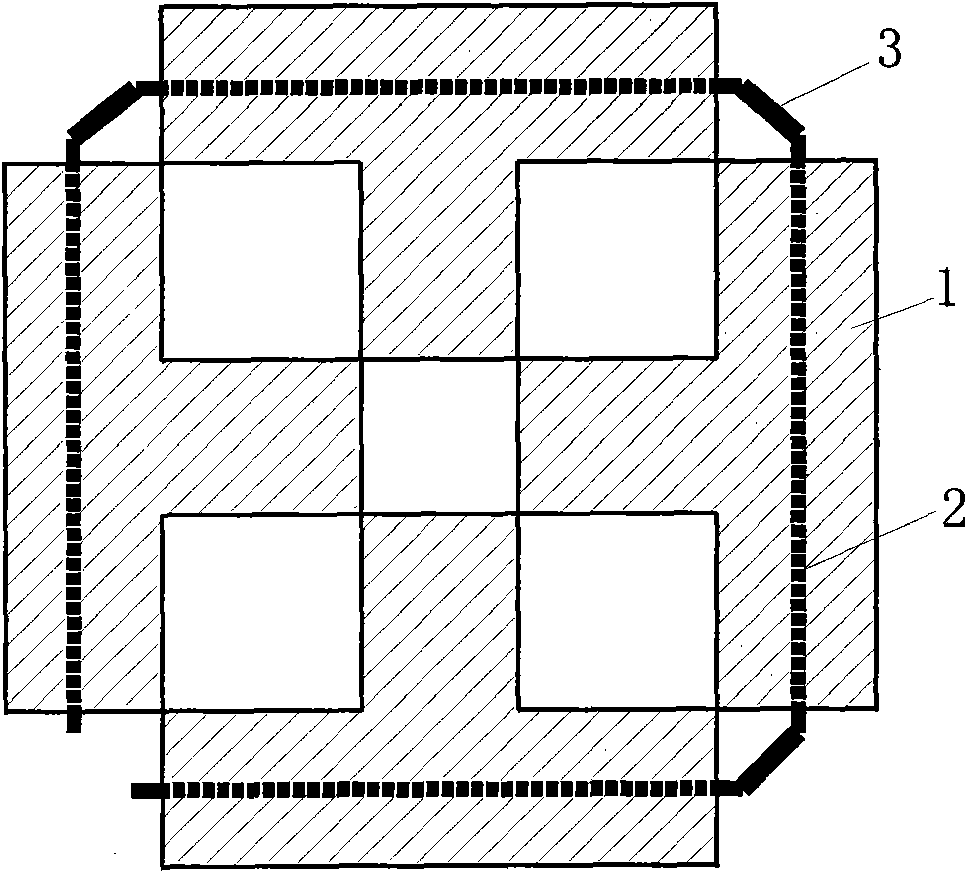

[0020] Arrange every four blocks 1 on the same horizontal plane according to the four sides of the rectangle to form a basic layer of the column. These four blocks correspond to the four types of blocks respectively, and are arranged clockwise or counterclockwise in the order of A, B, C, and D , and then the basic layers are stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com