Buckling-restraining and strengthening system for circular steel tubes

A buckling-constrained, round steel pipe technology, applied in the field of buckling-constrained reinforcement systems, can solve problems such as material waste, safety hazards, and strength decline, and achieve the effects of improving safety reserves, increasing bearing capacity, and simplifying construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

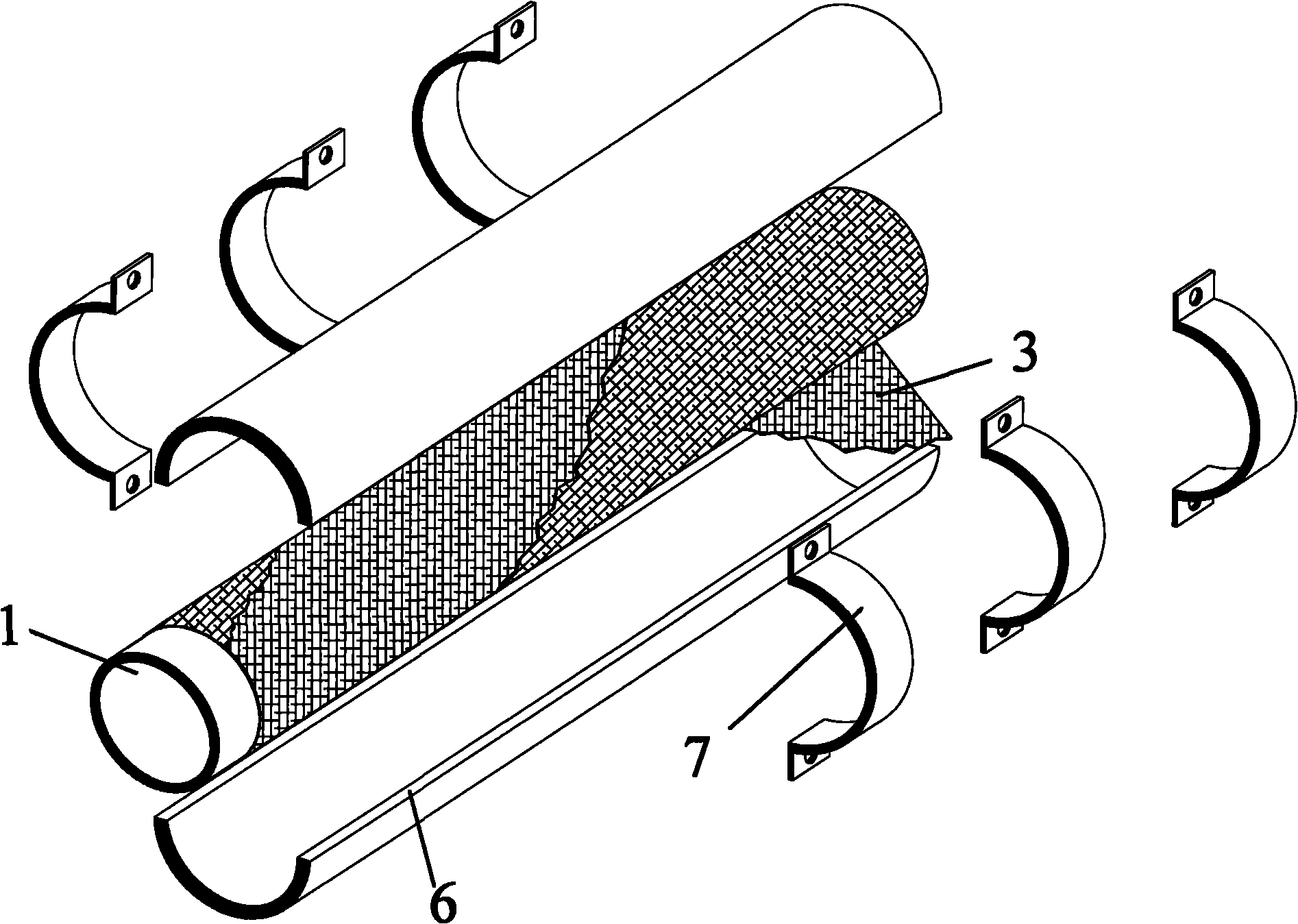

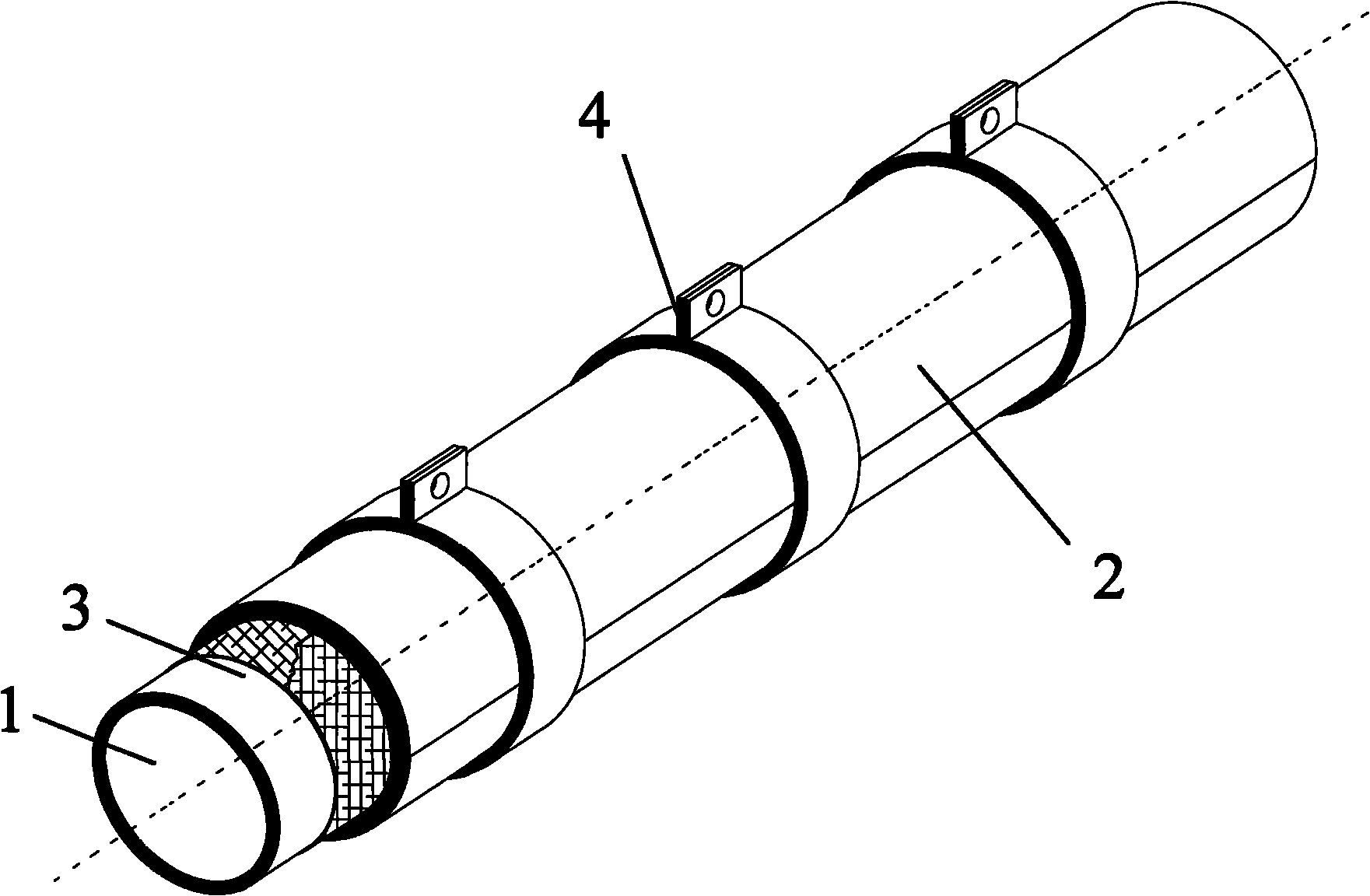

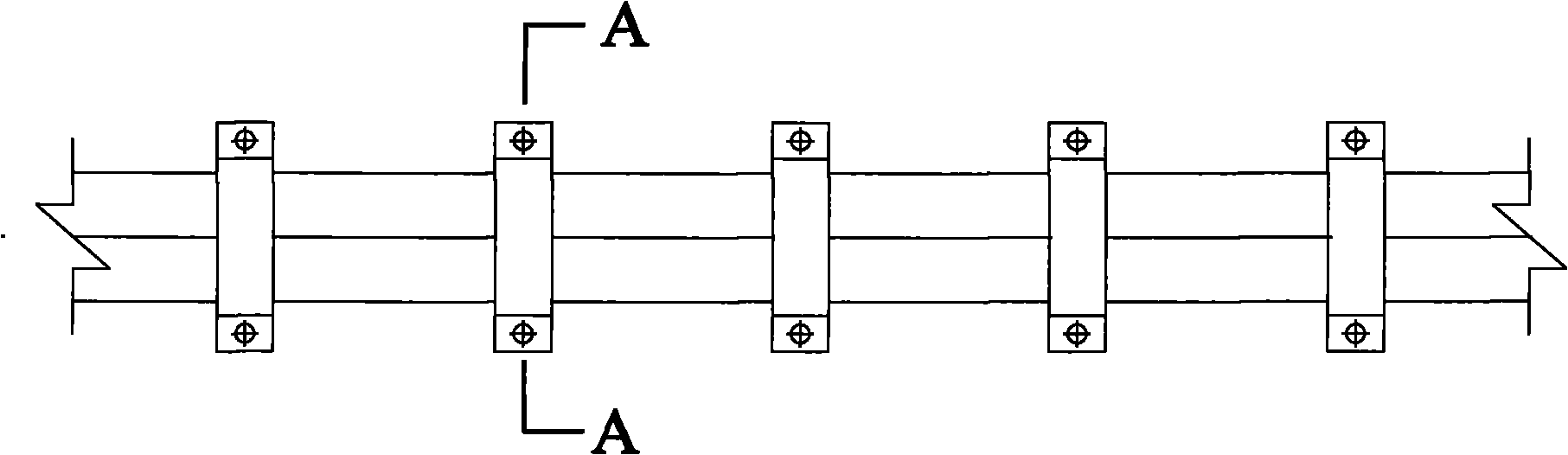

[0029] Embodiment 1: as Figure 1-Figure 4 As shown, the buckling-constrained strengthening system includes the following three parts: axial member unit 1, buckling-constrained unit 2 and debonding unit 3. Axial force component unit 1 is located at the center of the axis, which is the rod to be reinforced in the project, and only bears the axial pressure in the project; the buckling constraint unit 2 is wrapped around the axial force component unit 1, once the axial force component unit 1 buckles under compression deformation, the buckling restraint unit 2 will provide a transverse buckling restraint force to restrain the buckling instability of the axial member unit 1; The debonding effect between the two units is to avoid the axial interaction force between the axial force member unit 1 and the buckling restraint unit 2, so that the buckling restraint unit 2 only produces transverse buckling restraint on the axial force member unit 1 , and the debonding effect is a great fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com