LED heat radiation module

A technology of heat dissipation module and LED light source, applied in lighting and heating equipment, cooling/heating device of lighting device, lighting device, etc., can solve the problems of unstable performance, short service life, poor heat dissipation effect, etc. The effect of improving heat dissipation efficiency and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

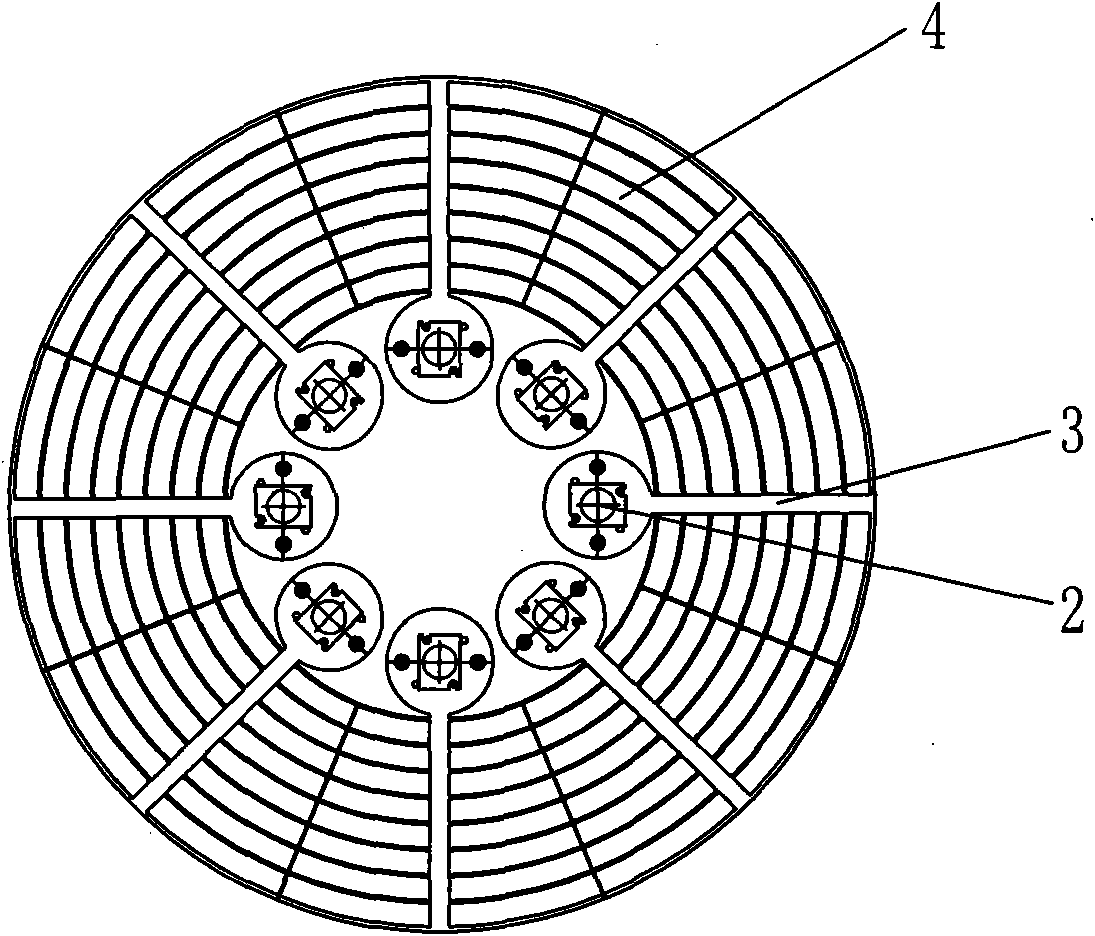

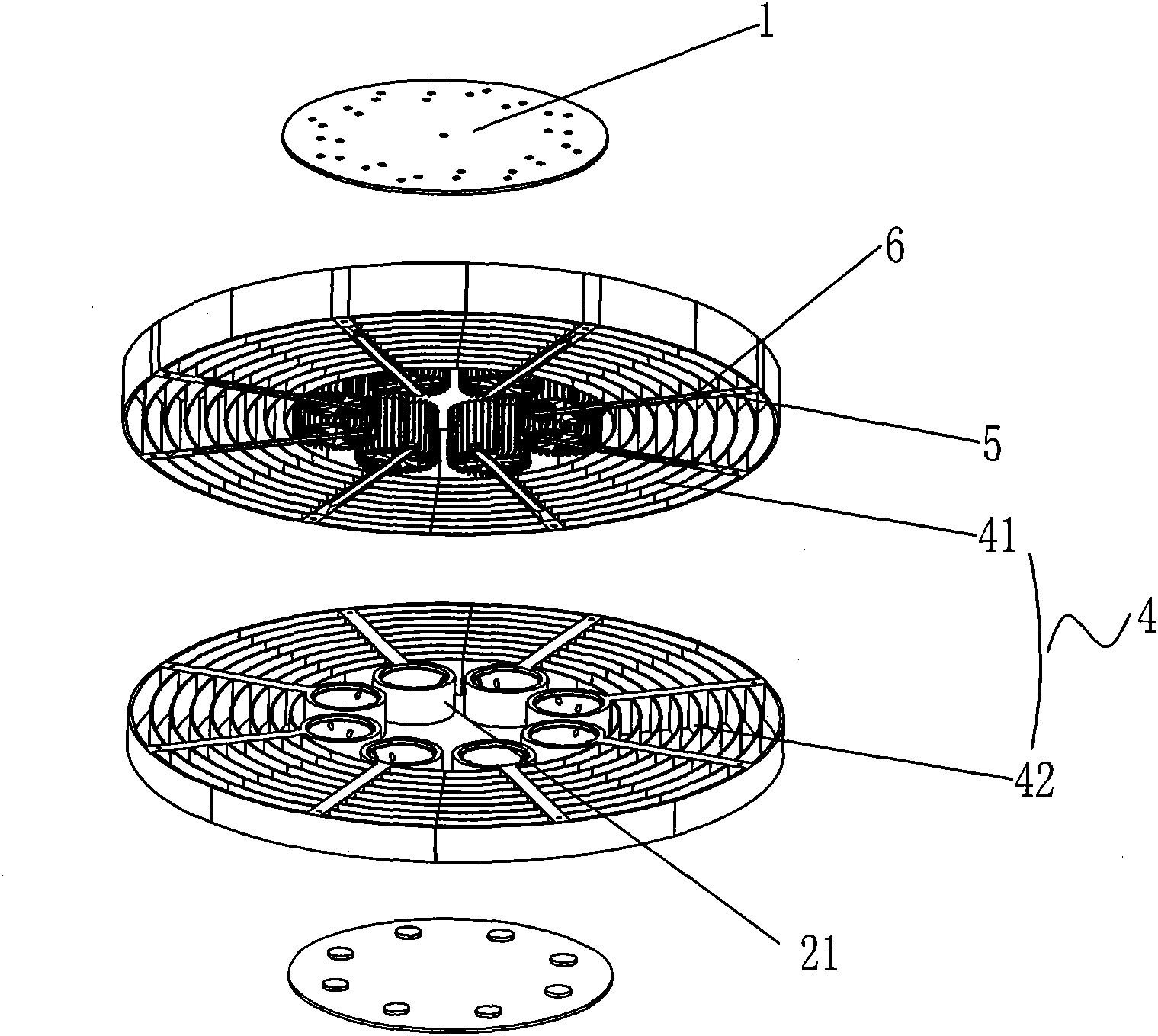

[0027] as attached Figure 1~3 As shown, what this embodiment discloses is an LED heat dissipation module with light weight and good heat dissipation effect. The heat dissipation module includes an LED light source module 2 driven by an LED driver and a heat sink connected to the LED light source module 2. The LED light source module 2 is installed in the center of the heat sink. Formed by fins 4, the LED light source module 2 is connected and installed on the ribs 3 of the heat sink. The heat emitted by the LED light source module 2 is conducted to the annular fins 4 through the ribs 3, and the air flows through the annular fins from bottom to top and natural convection. The heat on sheet 4 dissipates to the outside.

[0028] The annular fins 4 of the above-mentioned radiator include an upper annular fin 41 and a lower annular fin 42, and the upper and lower annular fins 41, 42 are fixedly connected to each other by a fixing member. On the upper and lower annular fins 41, 42...

Embodiment 2

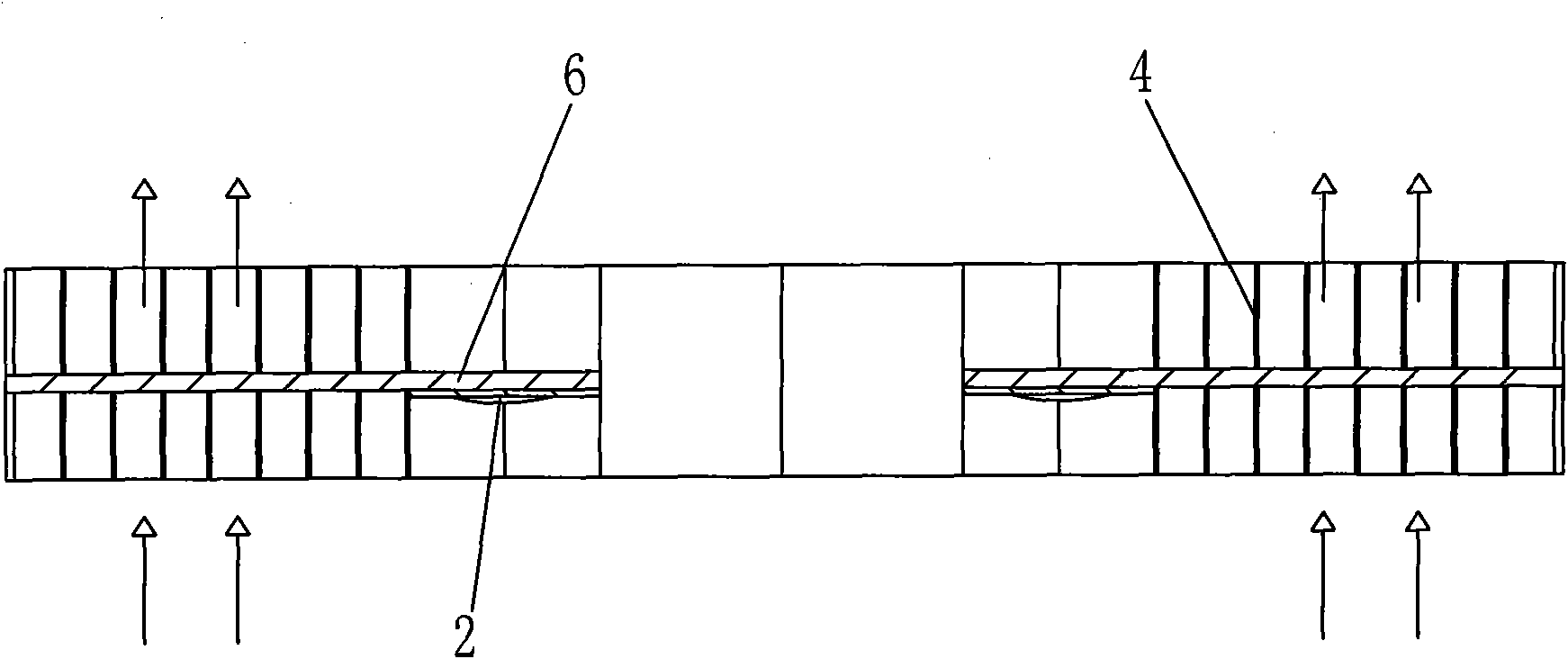

[0034] as attached Figure 9-10 As shown, the structure of the LED cooling module disclosed in this embodiment is similar to that in Embodiment 1, the difference is that one end of the heat pipe 6 is connected to a vapor chamber 7, the other end is installed in the heat conduction groove 5, and the LED light source module 2 is installed On the lower surface of the vapor chamber 7 , the LED driver is installed on the vapor chamber 7 and covered with the fixing plate 1 .

[0035] In this embodiment, when the heat generated by the operation of the LED light source module 2 is transferred to the soaking plate 7, the heat is conducted from the soaking plate 7 to the heat pipe 6, and the heat transfer liquid inside the heat pipe 6 absorbs heat and is evaporated, then condenses and releases heat in the heat conduction The inner surface of the condensing part of the tube 6 conducts the heat to the outer surface of the heat transfer tube 6, and the condensed liquid inside the heat tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com