Combustion chamber structure for heat exchanger

A technology for heat exchangers and combustion chambers, applied in the field of combustion chambers, can solve problems such as failure to achieve high-efficiency goals, affecting thermal efficiency, and insufficient combustion, reducing the generation of harmful gases such as carbon monoxide, increasing the heat-absorbing area, and the spread of combustion flames. short distance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

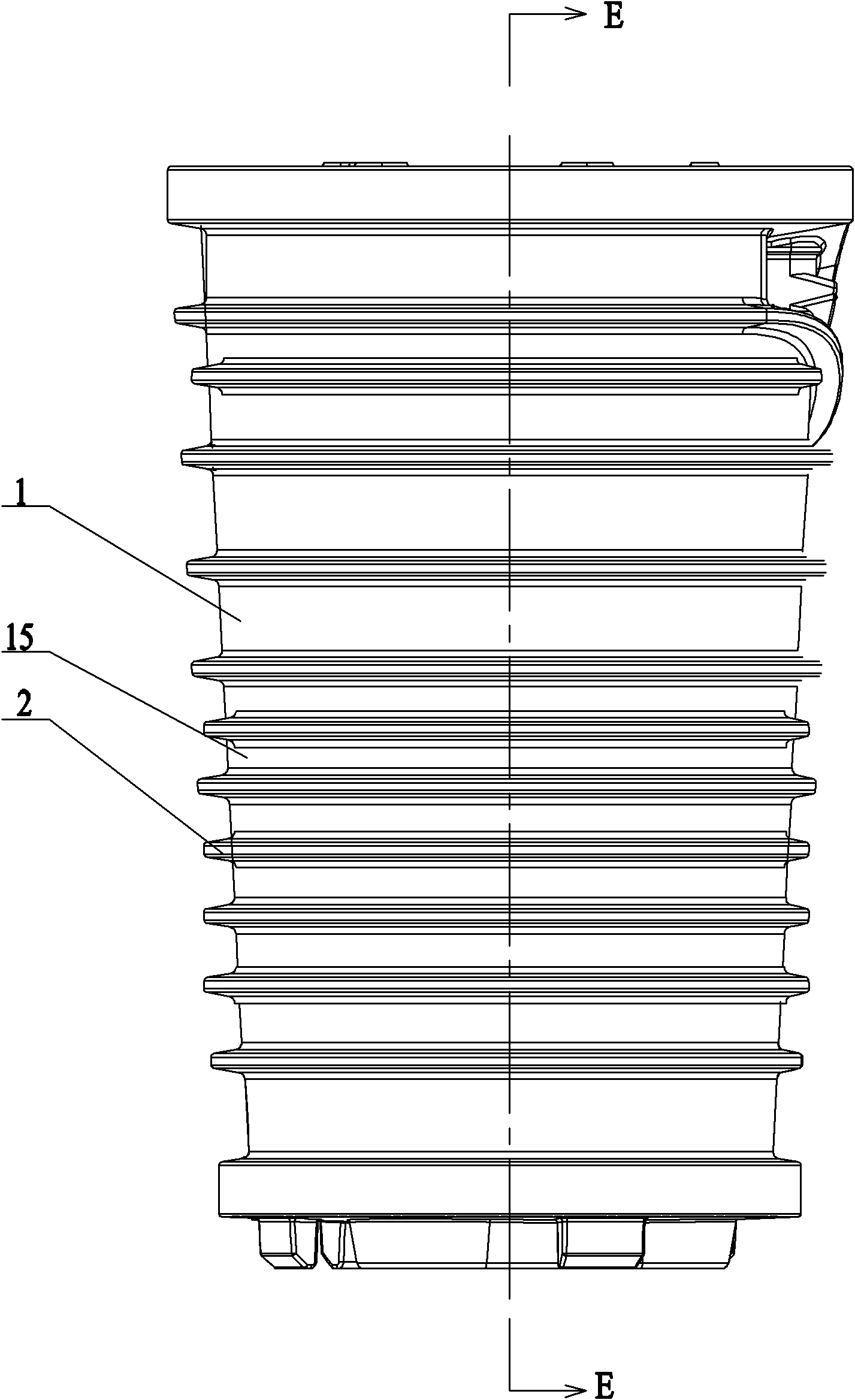

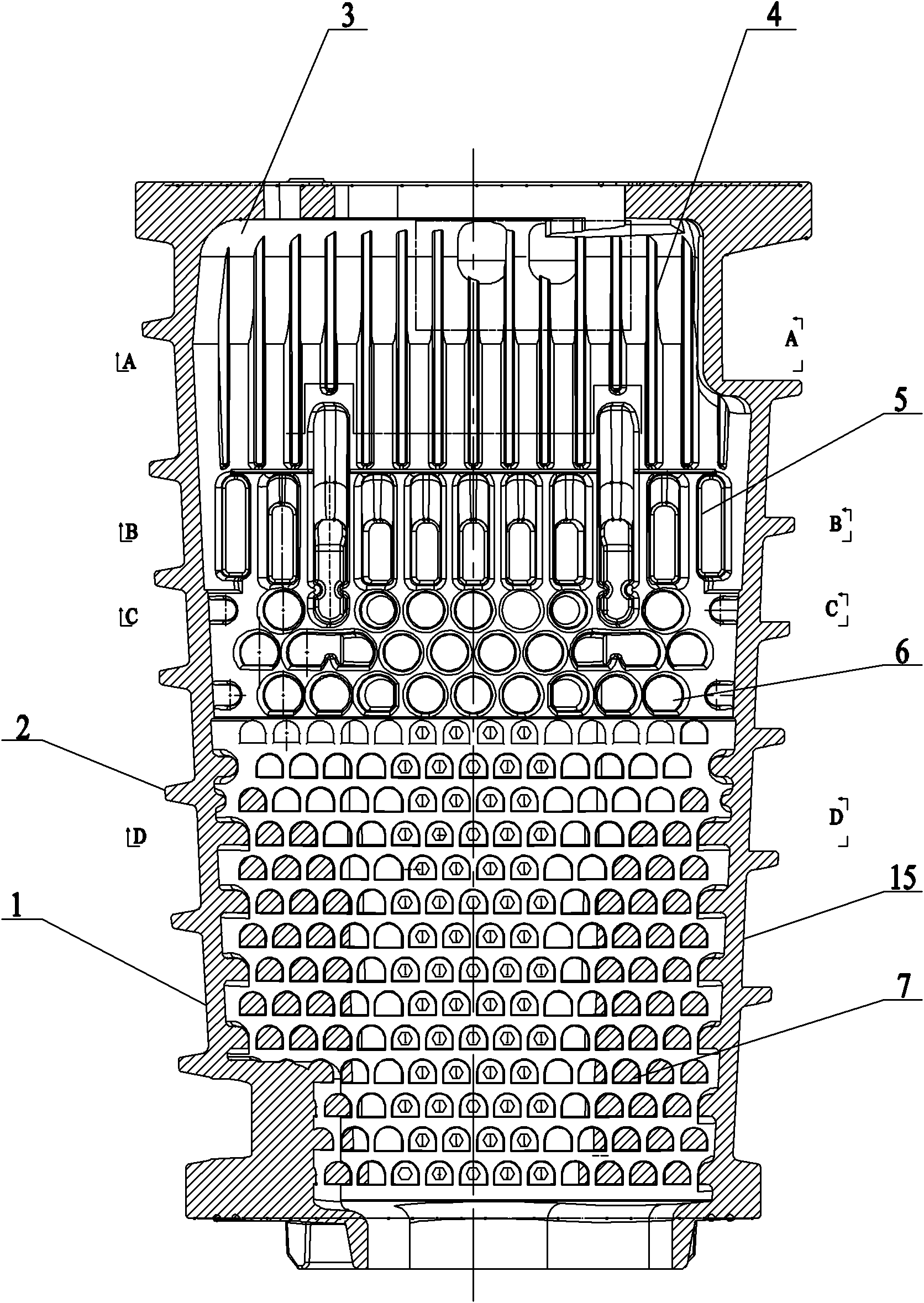

[0016] Such as Figure 1~Figure 7 As shown: the present invention includes a combustion chamber 1, a positioning boss 2, a combustion chamber cavity 3, a thin and long fin 4, a thick and short fin 5, a first heat exchange fin 6, a second heat exchange fin 7, a casing 8, and a water inlet pipe 9. Outlet pipe 10 , first airflow channel 11 , second airflow channel 12 , third airflow channel 13 , end cover 14 and heat transfer medium channel 15 .

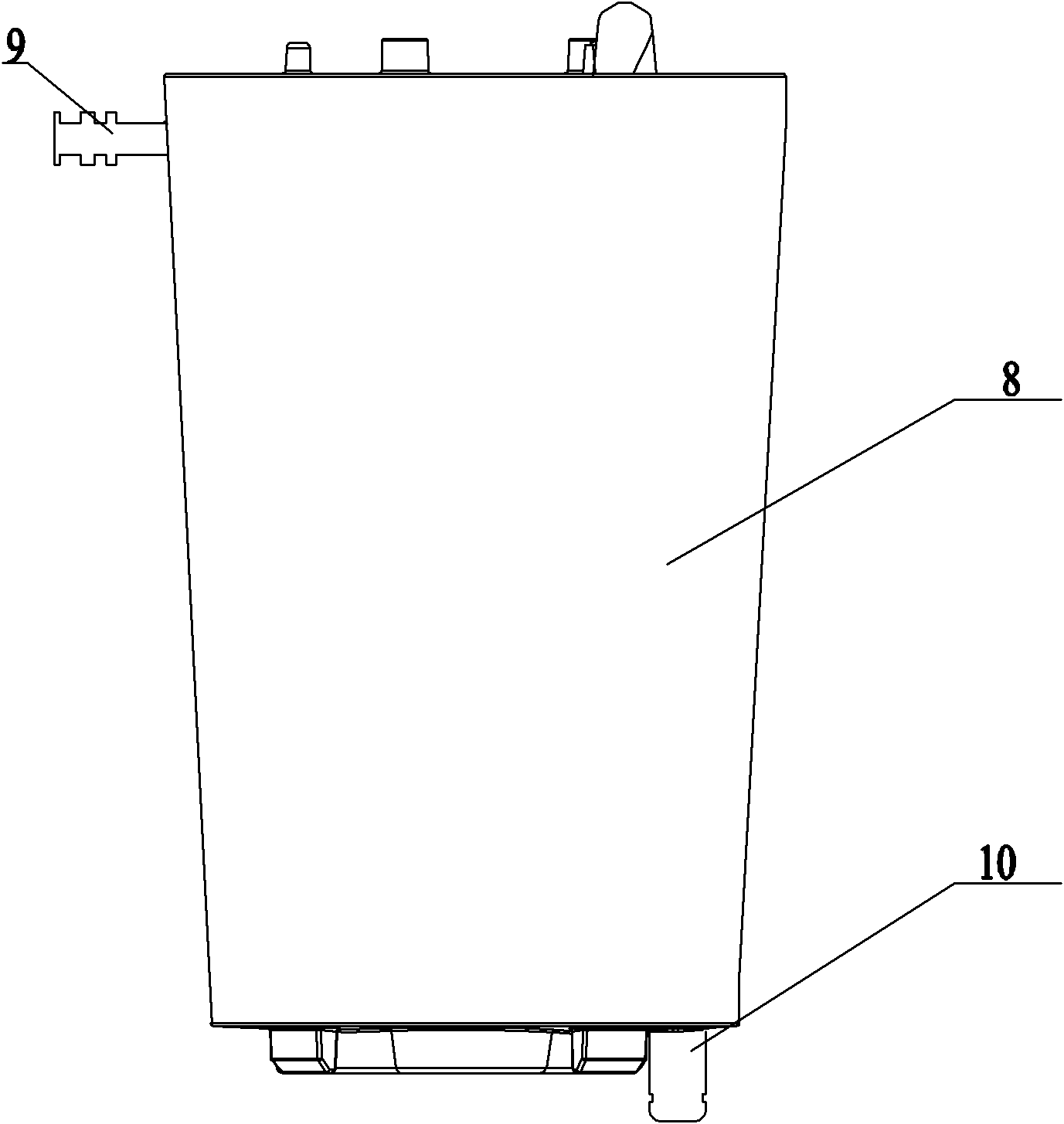

[0017] Such as figure 1 and figure 2 As shown: the heat exchanger includes an outer shell 8 and a combustion chamber 1 located in the outer shell 8, the outer wall of the combustion chamber 1 is provided with a positioning boss 2 that closely fits the combustion chamber 1, so There are a plurality of positioning bosses 2, which are evenly distributed along the outer peripheral surface of the combustion chamber 1; heat transfer medium channels 15 are formed between adjacent positioning bosses 2; and a combustion chamber cavity 3 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com