Xenon short arc lamp for digital a projector

A technology for projectors and short-arc lamps, applied to gas discharge lamps, parts of gas discharge lamps, discharge lamps, etc., can solve problems such as the end of life, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

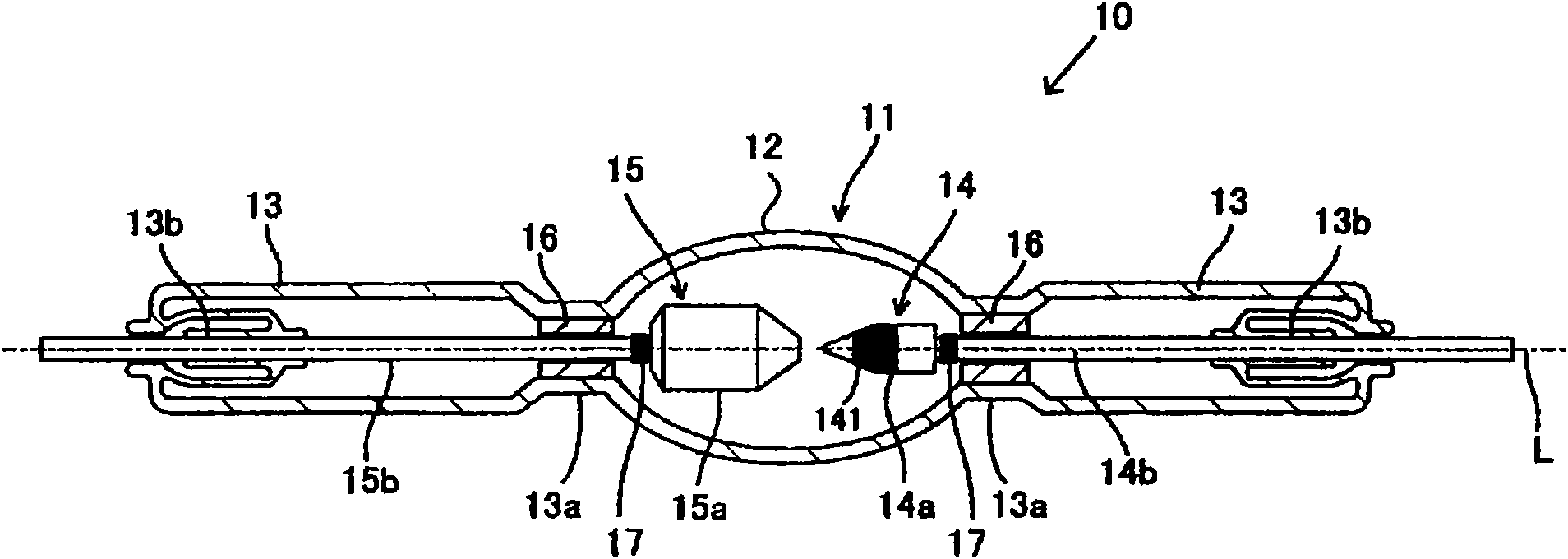

[0148] Lamp 2 (reference example 2) is a xenon short-arc lamp for digital projectors for DLP, and the sealing pressure, the current density at the tip of the cathode, and the load on the tube wall are set high in order to be a high-intensity lamp. The specific specifications are as above.

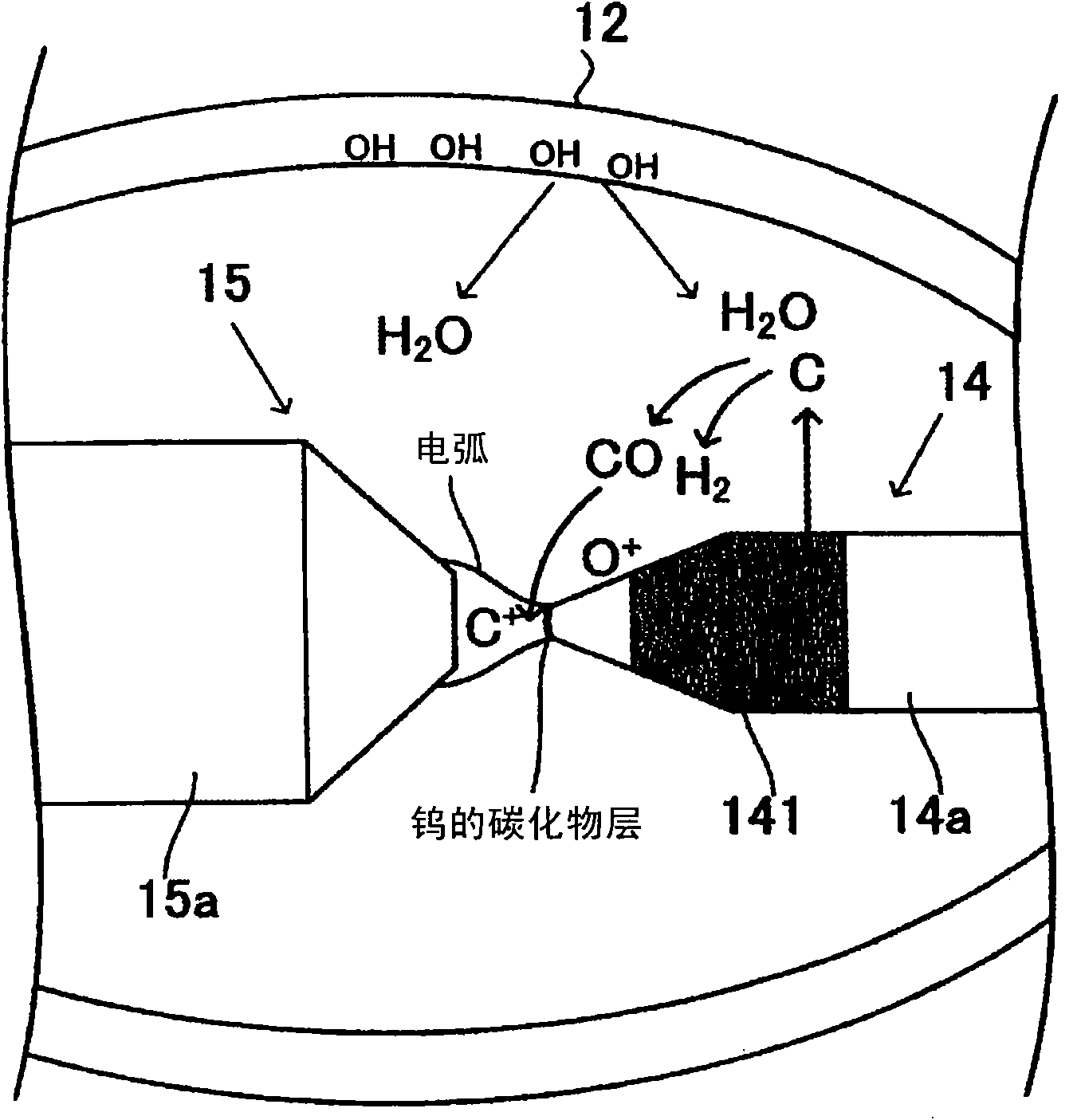

[0149] In the molding process of the arc tube, when the arc tube is expanded, the same dry gas (N2) as that of the above-mentioned lamp 1 is used, and the concentration of the OH group in the inner surface of the arc tube is maintained at the level of the raw material before molding, and is as low as 5 wt-ppm . Also, as in lamp 1, a carbide layer was formed on the surface of the tapered portion of the cathode body by a conventionally known method, and a tantalum getter was arranged inside the arc tube.

[0150] The lamp 2 thus turned on has a flicker life of 260 hours, which is an extremely short life compared with the lamp 1 .

[0151] In addition, analyzing lamp 2, the total carbon cont...

Embodiment 1

[0162] Then, the lamp 4 (Example 1) in which the amount of carbon in the arc tube was increased was fabricated.

[0163] In addition, in the lamp 4 (Example 1), it is the same as the lamp 3 (Reference example 3) in that a light-emitting tube having an increased OH group concentration in the inner surface layer is used as a long-term water supply source.

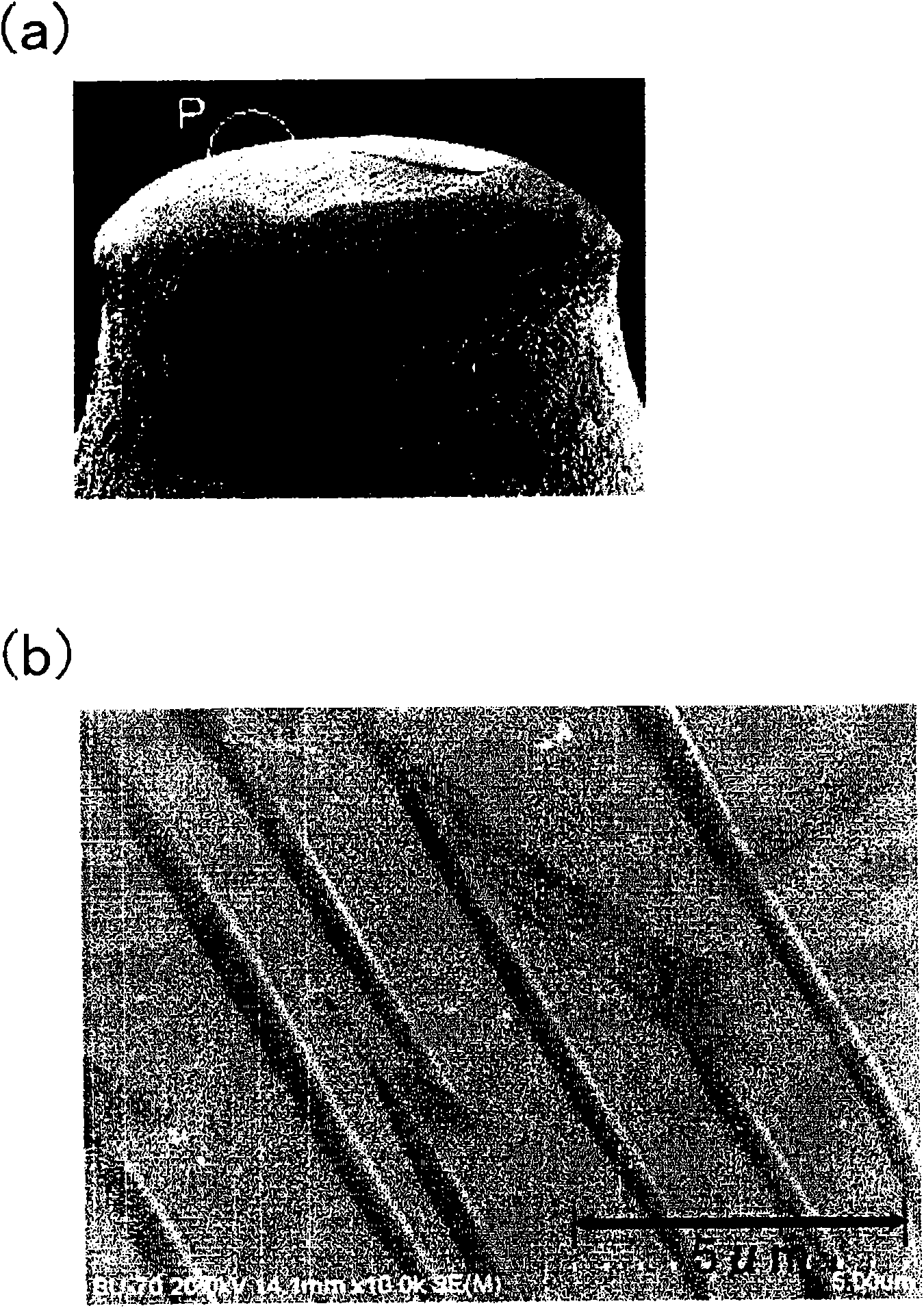

[0164] Here, various studies were conducted as a method for increasing the amount of carbon, but in this example, the amount of carbon was increased by increasing the area of the surface of the cathode to be carbonized. For example, in the carbonized layer forming step, the amount of carbon existing inside the arc tube, that is, the front end of the cathode can be adjusted according to the amount of the coating agent containing carbon, the area of the region where the carbonized layer is formed, the temperature of the high-temperature carburizing treatment, and the like. The amount of carbon configured on the carbide layer ...

Embodiment 2

[0168] A lamp 5 (Example 2) having the same structure as the above lamp 4 (Example 1) except that the amount of carburization of the cathode was further increased was fabricated. When the lamp 5 is turned on, the flickering lifespan is 540 hours, which can further prolong the lifespan. Analyze the amount of carbon in the lamp 5, relative to 1 cm of the inner volume of the luminous tube 3 is 3.0 μmol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com