Method for producing an individual cell for a battery

A battery cell and cell technology, applied in secondary batteries, secondary battery manufacturing, battery pack components, etc., can solve problems such as damage or destruction of components, increase cost, time consumption, etc., to simplify the structure, reduce Scrap, the effect of improving the vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Corresponding parts have the same reference numerals in all figures.

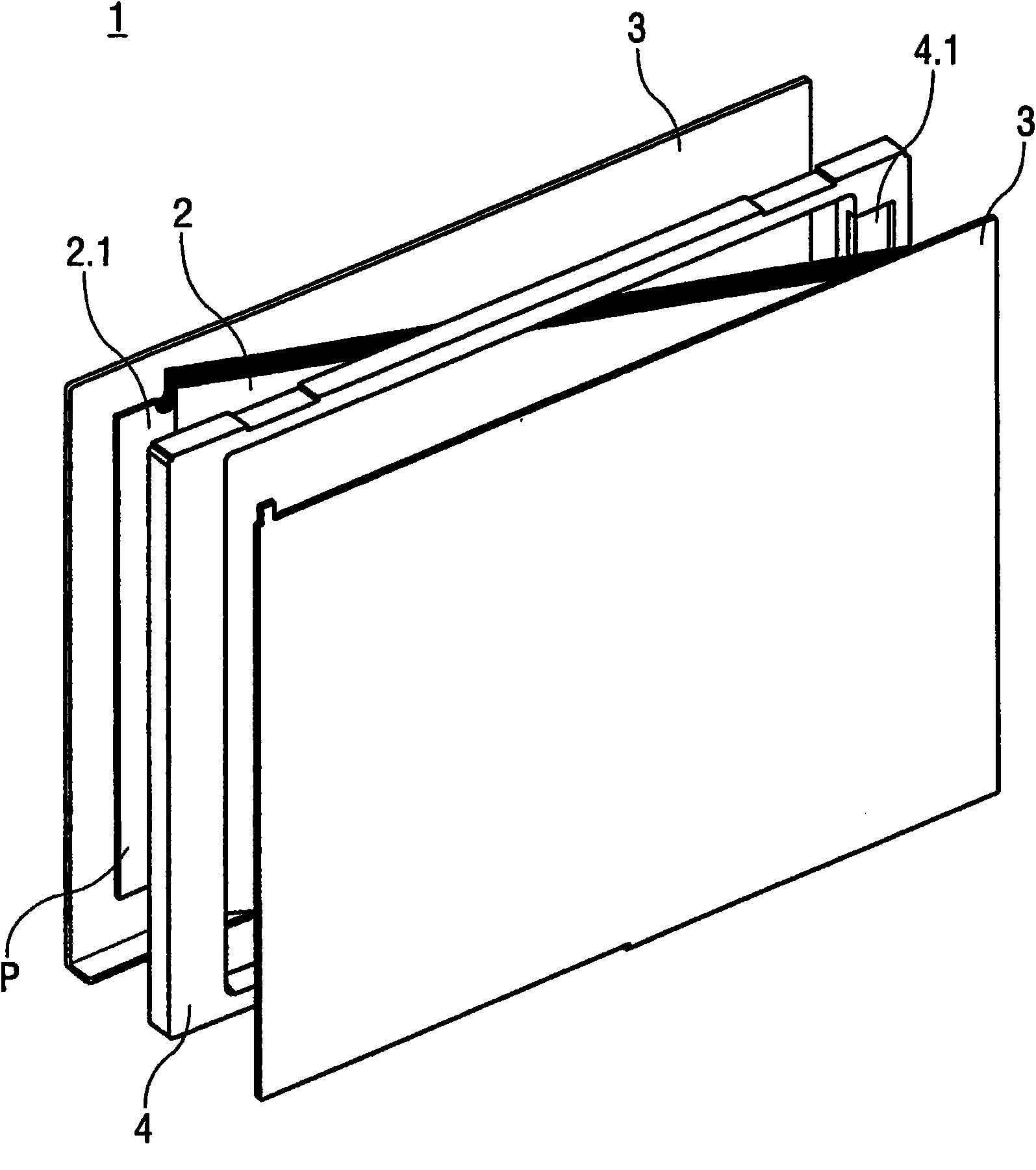

[0029] figure 1 A monoblock 1 designed as a frame flat monolith is shown in the opened state.

[0030] The cell 1 comprises an electrode stack 2 arranged in a cell housing, wherein the cell housing has two electrically conductive housing side walls 3 , in particular planar sides, and a An electrically insulating frame 4 surrounding the edges.

[0031] In this case, the electrode stack 2 is in particular formed by membrane electrodes (not shown in detail), wherein in the central region of the electrode stack 2 membrane electrodes of different polarity, in particular aluminum and / or copper foils and / or made of metal The alloy films are stacked on top of each other and are electrically insulated from one another by means of separators, not shown in detail, in particular separator films.

[0032] Membrane electrodes of the same polarity are electrically connected to one another and form pole contacts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com