Method for preparing cement mortar

A technology of cement mortar and cement, which is applied in the field of building materials, can solve problems such as unsatisfactory modification effects, and achieve the effects of improved resistance to chloride ion erosion, improved tensile strength, and improved bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

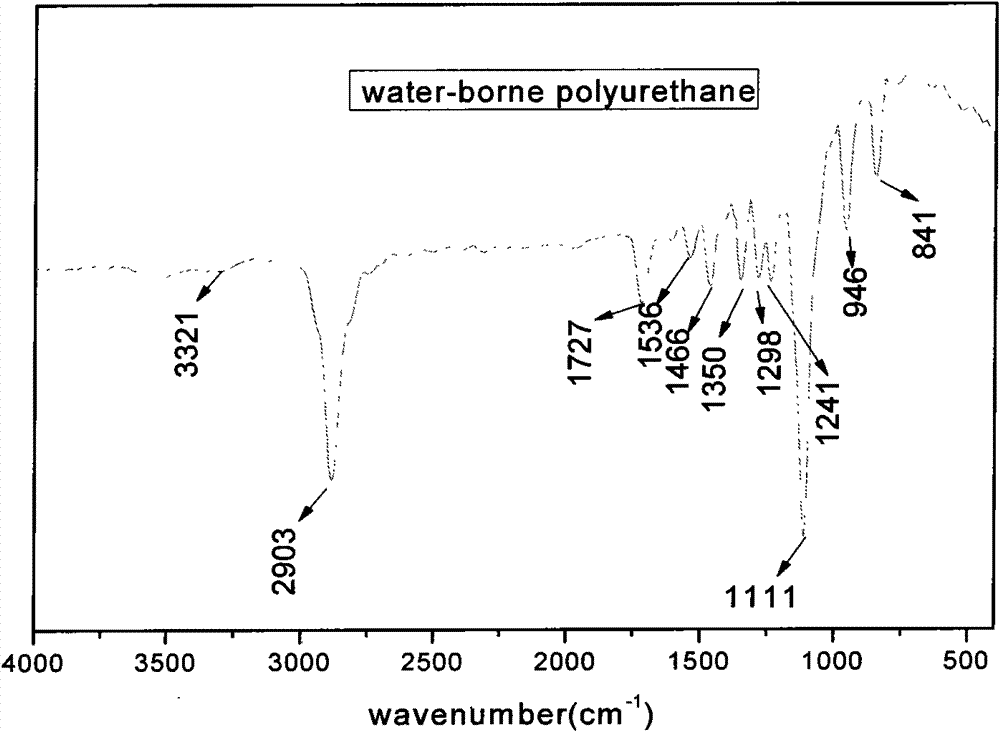

Image

Examples

Embodiment 1

[0024] Take 600 grams of cement, 1200 grams of fine sand, and 0.324 grams of cellulose, put them in a blender and manually stir them evenly, then add 250 grams of water, and after the manual mixer stirs at a slow speed, add 5.4 grams of polycarboxylate superplasticizer solution ( There are 0.216 grams of sodium gluconate) manual mixer at a slow speed and stir evenly, add 200 grams of water-soluble polyurethane solution and manually stir evenly, then add 100 grams of water, then turn the mixer to automatic, stir slowly for one minute, and stir quickly for one minute Minutes, stop for one minute, and stir for another minute, inject the new mortar that has been stirred into a mold, and put it in a cement mortar standard curing box for curing. The flexural compressive strength and elastic modulus of the 28-day cement mortar were measured to be 6.0MPa, 50MPa, and 10500MPa respectively

Embodiment 2

[0026] Take 600 grams of cement, 1200 grams of fine sand, and 0.324 grams of cellulose, put them in a blender and manually stir them evenly, then add 250 grams of water, and after the manual mixer stirs at a slow speed, add 5.4 grams of polycarboxylate superplasticizer solution ( There are 0.216 grams of sodium gluconate) manual mixer and stir at a slow speed, add 150 grams of water-soluble polyurethane solution and manually stir evenly, then add 100 grams of water, then turn the mixer to automatic when stirring slowly for one minute and stir quickly for one minute Stop for one minute and then stir for another minute, inject the new mortar that has been stirred into a mold, and put it in a cement mortar standard curing box for curing. The flexural compressive strength and elastic modulus of the cement mortar measured for 28 days were 5.5MPa, 54MPa, and 1257MPa, respectively.

Embodiment 3

[0028] Take 600 grams of cement, 1200 grams of fine sand, and 0.324 grams of cellulose, put them in a blender and manually stir them evenly, then add 250 grams of water, and after the manual mixer stirs at a slow speed, add 5.4 grams of polycarboxylate superplasticizer solution ( There are 0.216 grams of sodium gluconate) manual mixer and stir at a slow speed, add 250 grams of water-soluble polyurethane solution and manually stir evenly, then add 100 grams of water, and then adjust the mixer to automatic when stirring slowly for one minute and stirring quickly for one minute Stop for one minute and then stir for another minute, inject the new mortar that has been stirred into a mold, and put it in a cement mortar standard curing box for curing. The flexural compressive strength and elastic modulus of the cement mortar measured for 28 days were 5.2MPa, 43MPa, and 9675MPa, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com