Reactor composting device for aerobic fermentation

An aerobic fermentation and reactor technology, applied in fertilization devices, applications, organic fertilizers, etc., can solve problems such as ammonia evaporation, and achieve the effects of maintaining the temperature of the heap and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

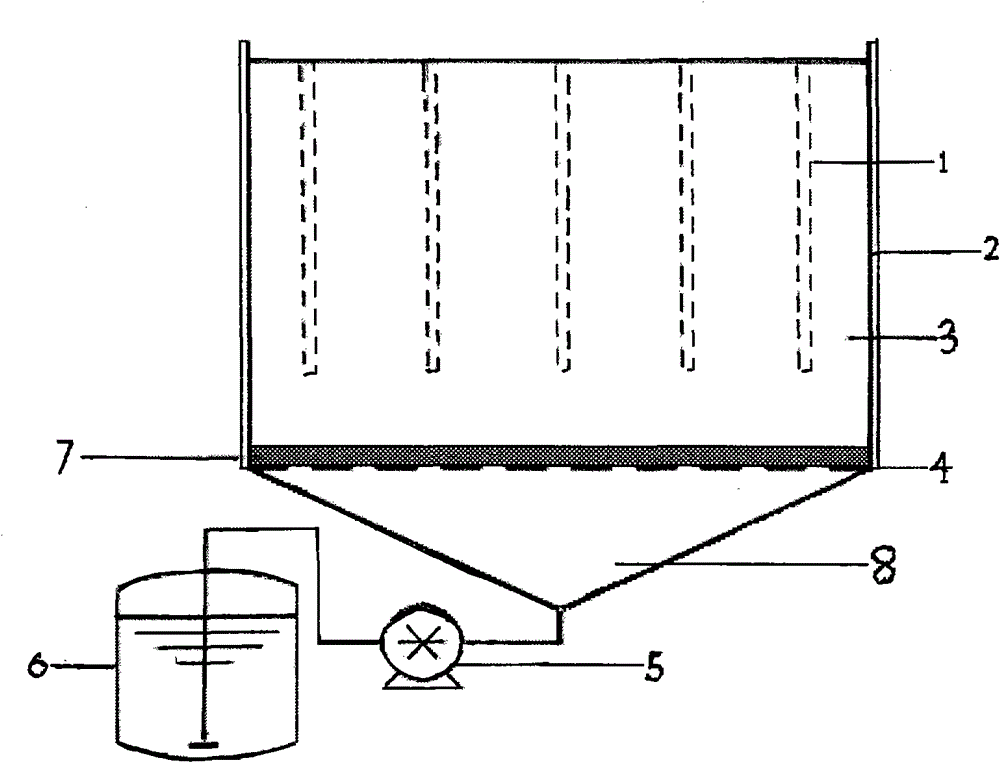

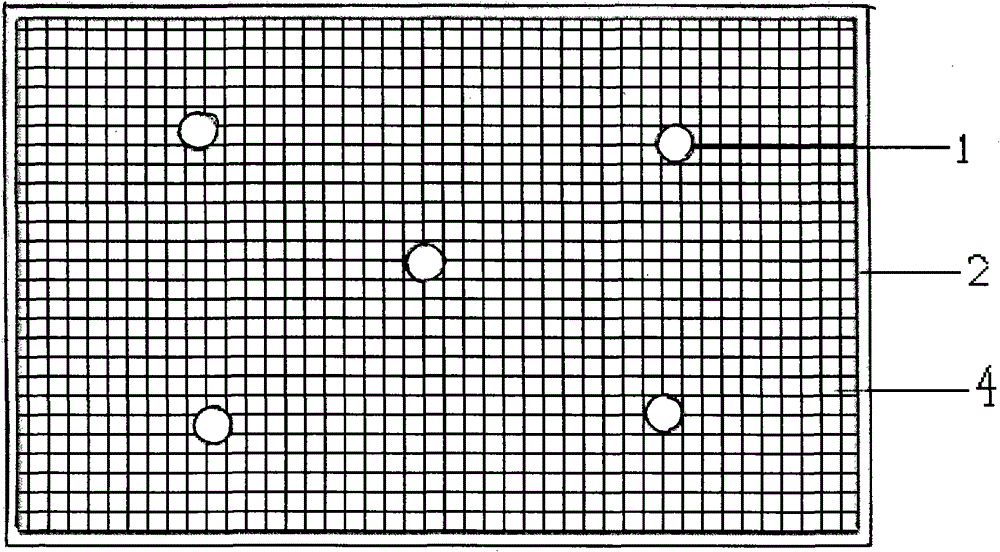

[0017] Such as figure 1 with figure 2 As shown, this novel compost reactor device includes a fermentation system and a conical gas collection tank 8. The fermentation system consists of a cuboid fermentation tank 3 and a conical gas collection tank 8. The wall of the fermentation tank 3 has a 1cm insulation layer 2, and at the bottom of the fermentation tank 3 is a 10cm cushion layer 7 and a stainless steel screen 4. In the fermentation tank 3, 5 plastic air pipes 1 with a diameter of 3 cm with holes are evenly distributed, and the bottom ends of the plastic air pipes 1 pass through the pad layer 7 and are fixed on the stainless steel screen 4. The gas collection treatment system is composed of a conical gas collection tank 8 and a gas treatment system. The gas collection tank 8 is located below the fermentation tank 3 and is closely connected with the fermentation tank 3. The gas treatment system is composed of an air pump 5 and an ammonia gas absorption tank 6 . The air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com