Method for constructing constant-temperature region by multi-surface heating in vacuum

An area and vacuum technology, which is applied in the field of film growth or film preparation, and batch preparation of large-area films, can solve the problems of substrate atom evaporation and achieve the effect of good temperature area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Example: One can grow 2*10 in a single time 6 mm 2 Graphene film device

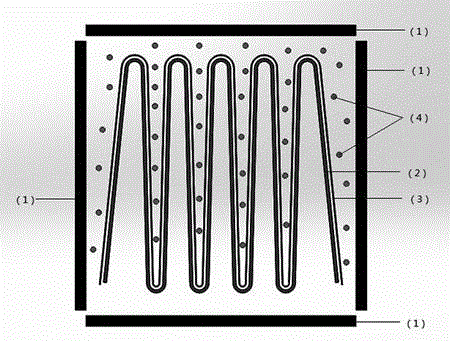

[0023] 1. Refer to the instructions attached figure 1 , The heating device (1) uses a resistance heating source, and the resistance uses high-purity graphite with a cross-section of 18mm*5mm; the substrate (2) uses a copper (Cu) substrate;

[0024] 2. Use the four-sided heating device described in step 1 to construct a 500mm*500mm*800mm space with two empty ends; the entire device is clamped and placed in a vacuum chamber;

[0025] 3. Use C 2 H 4 When the copper (Cu) substrate is heated to a high temperature of 1000 degrees Celsius under the protection of inert gas, the carbon-containing compounds begin to decompose and graphene is formed on the surface of the copper substrate;

[0026] Using the above-mentioned four-sided heating device stacking scheme, a single reaction can grow into a stable, high-quality graphene film with an area of 2*10 6 mm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com