Method for preparing cation synthetic sperm oil fat liquor

A technique for spermaceti oil and fatliquor, which is applied in the field of preparation of cationic fatliquor, can solve the problems of poor leveling, uniformity of stability, defect in permeability, large influence on dyeing, etc. Visible, solid color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

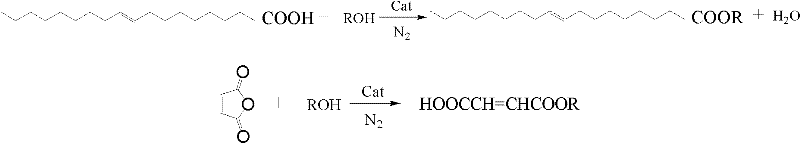

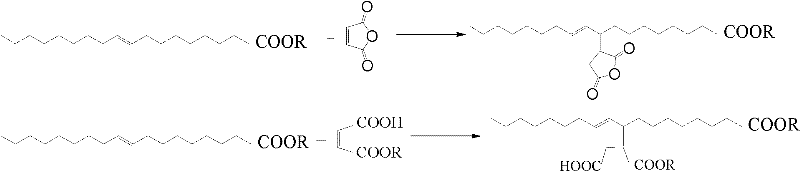

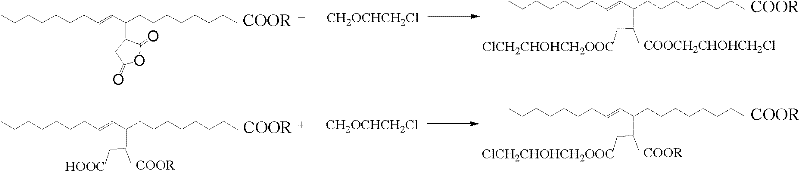

Method used

Image

Examples

Embodiment 1

[0055] With 282g soybean oil fatty acid and 270g oleyl alcohol, add in the reactor, add p-toluenesulfonic acid catalyst, pass N 2 Protect under the surface of the reaction liquid, and act as agitator with water, and react at 140-160°C for 2 hours to obtain synthetic cetyl oil with an acid value of 1.33 mgKOH / g. Cool the resulting synthetic cetyl oil to about 60°C, add 98g of maleic anhydride, heat up, stir, and pass N 2 protection, control the reaction temperature at about 200°C, react for 3.5 hours, and then lower the temperature to about 70°C to obtain maleic anhydride-modified synthetic cetyl oil. Add 185g of epichlorohydrin, control the reaction temperature at 80-95°C, react for 3h, and recover excess epichlorohydrin. Then add 300 g of triethanolamine, control the reaction temperature at 50-70° C., and react for 2 hours to obtain a cationic synthetic cetyl oil fatliquoring agent.

[0056] After testing, the cationic synthetic cetyl oil prepared in this example is a reddi...

Embodiment 2

[0058] Add 282g linseed oil fatty acid and 270g oleyl alcohol into the reactor, add an appropriate amount of p-toluenesulfonic acid catalyst, pass N 2 Protect under the surface of the reaction liquid, and act as agitator with water, and react at 140-160°C for 3 hours to obtain synthetic cetyl oil with an acid value of 1.10 mgKOH / g. The resulting synthetic cetyl oil is cooled to 70°C, 98g of maleic anhydride is added, the temperature rises and the reaction is stirred, and the N 2 Protect, control the reaction temperature at 200°C, react for 3 hours, and lower the temperature to 70°C to obtain maleic anhydride-modified synthetic cetyl oil. Add 185g of epichlorohydrin, control the reaction temperature at 80-95°C, react for 3h, and recover excess epichlorohydrin. Then add 180g of triethylamine, control the reaction temperature at 50-70°C, react for 2-4h, and recover the excess triethylamine with a rotary evaporator to obtain a cationic synthetic cetyl oil fatliquor.

[0059] Aft...

Embodiment 3

[0061] Add 280g oleic acid and 270g oleyl alcohol into the reactor, add an appropriate amount of p-toluenesulfonic acid catalyst, pass N 2 Protect under the surface of the reaction liquid, and act as agitator with water, and react at 140-160°C for 3 hours to obtain synthetic cetyl oil with an acid value of 1.13 mgKOH / g. The gained synthetic spermaceti oil is cooled to about 70 ℃, adds 90g maleic anhydride, heats up and stirs reaction, and passes N 2 Protect, control the reaction temperature at 200°C, react for 3.5 hours, and lower the temperature to 75°C to obtain maleic anhydride-modified synthetic cetyl oil. Add 185g of epichlorohydrin, control the reaction temperature at 80-95°C, react for 3h, and recover excess epichlorohydrin. Then add 300g of triethanolamine, control the reaction temperature at 50-70°C, and react for 2-4h. A cationic synthetic cetyl oil fatliquor is obtained.

[0062] After testing, the cationic synthetic cetyl oil prepared in this example is a reddis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com