Composite door and manufacture process thereof

A preparation process and composite door technology, which is applied to door leaves, windows/doors, building components, etc. It can solve the problems of easy cracking of composite doors, easy deformation of the door body, and long production cycle, so as to prevent deformation, bending and cracking, and enhance moisture resistance Performance and bonding firm performance, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

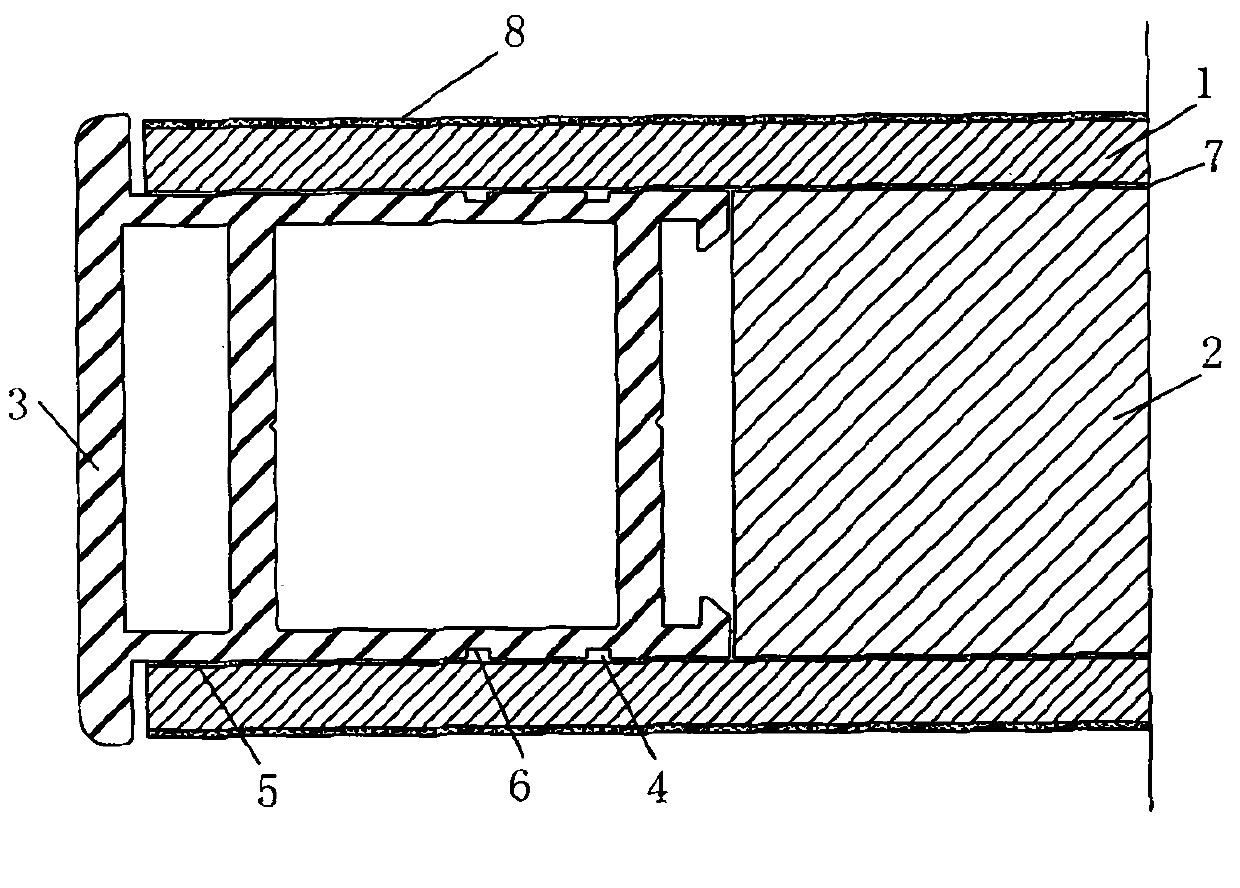

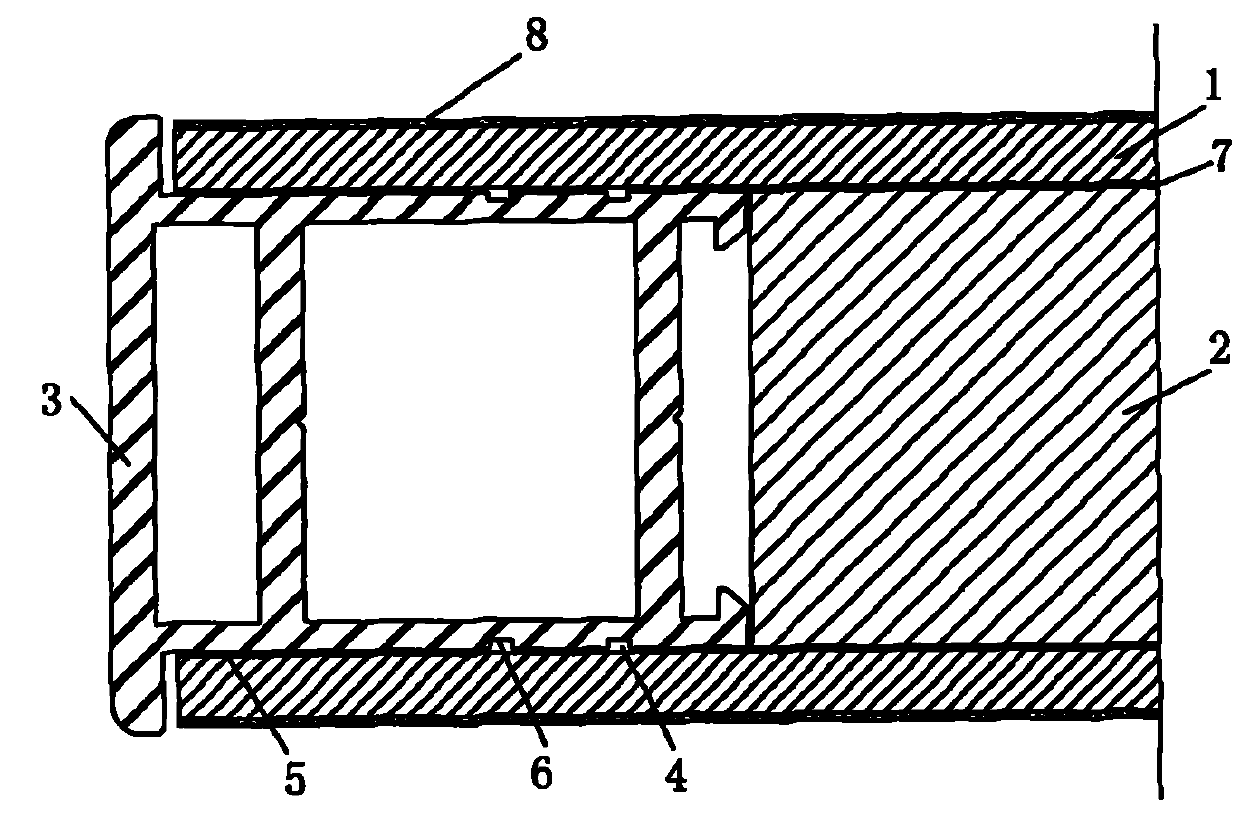

[0030] Such as figure 1 As shown, the present invention includes a door core 2, a door panel 1 and a keel edge banding 3, the door panel 1 is adhered to both sides of the door core 2, the inner surface of the door panel 1 is provided with a melamine layer 7, and the door panel 1 and the door core 2 are glued together. The keel edge banding 3 is made of aluminum profiles, the keel edge banding 3 is provided with a groove 6 and an adhesive layer, and the adhesive layer is composed of a double-sided adhesive layer 5 and a liquid adhesive layer 4 .

[0031] Preparation technique of the present invention comprises the following steps:

[0032] Prefabricated edge banding: choose aluminum profiles, process the keel according to the size of the door body, pre-mill the keyhole and hinge hole, and set grooves on both sides of the keel to form the keel edge banding;

[0033] Glue coating: acrylic double-sided adhesive tape and polyurethane structural adhesive are coated sequentially on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com