Flow control method of combustion system

A flow control and combustion system technology, applied in the combustion method, combustion control, and fuel supply adjustment, etc., can solve the problems of slow valve adjustment, unstable combustion, insufficient, etc., to improve product quality, avoid combustion instability, Combustion system stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

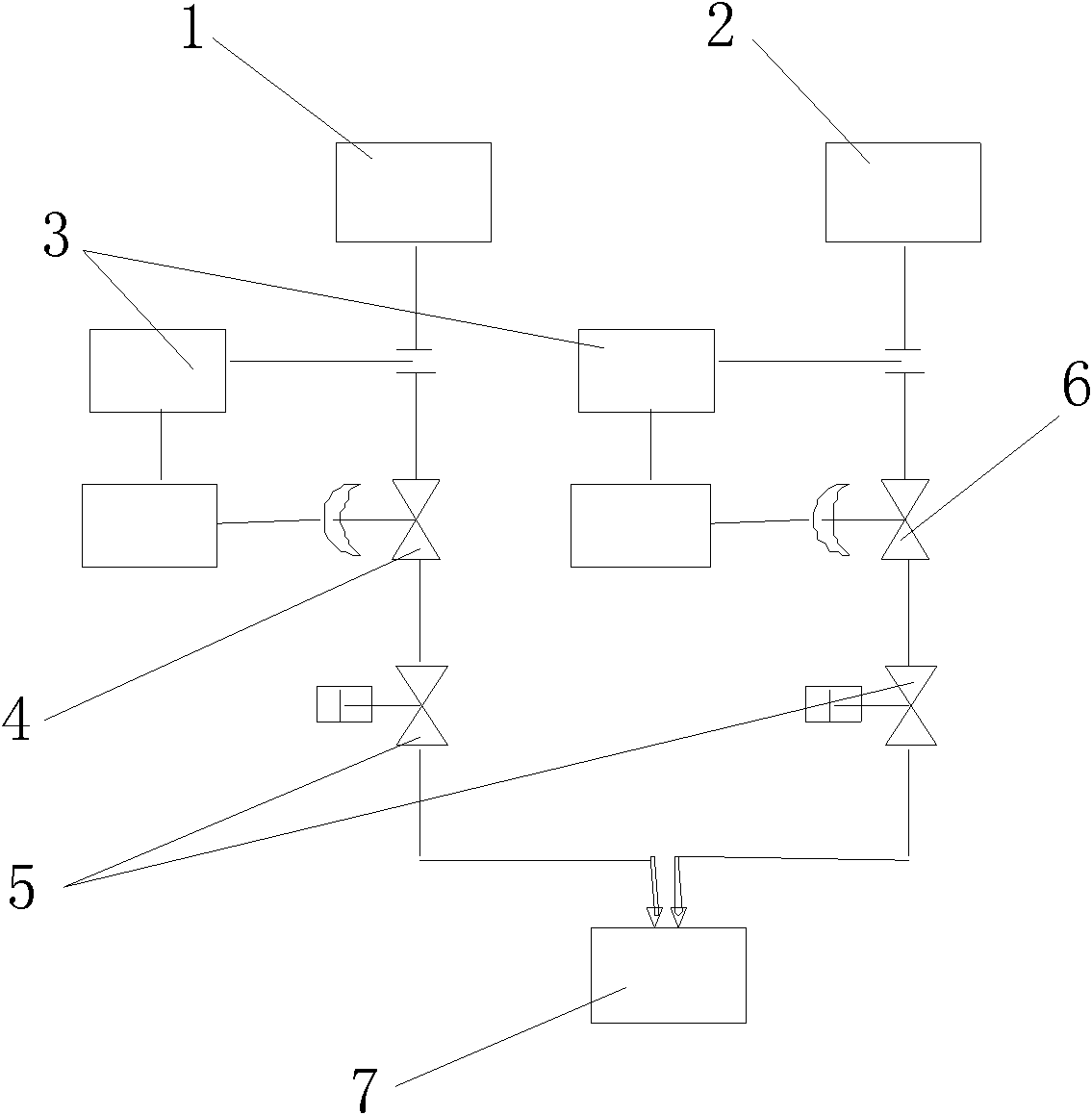

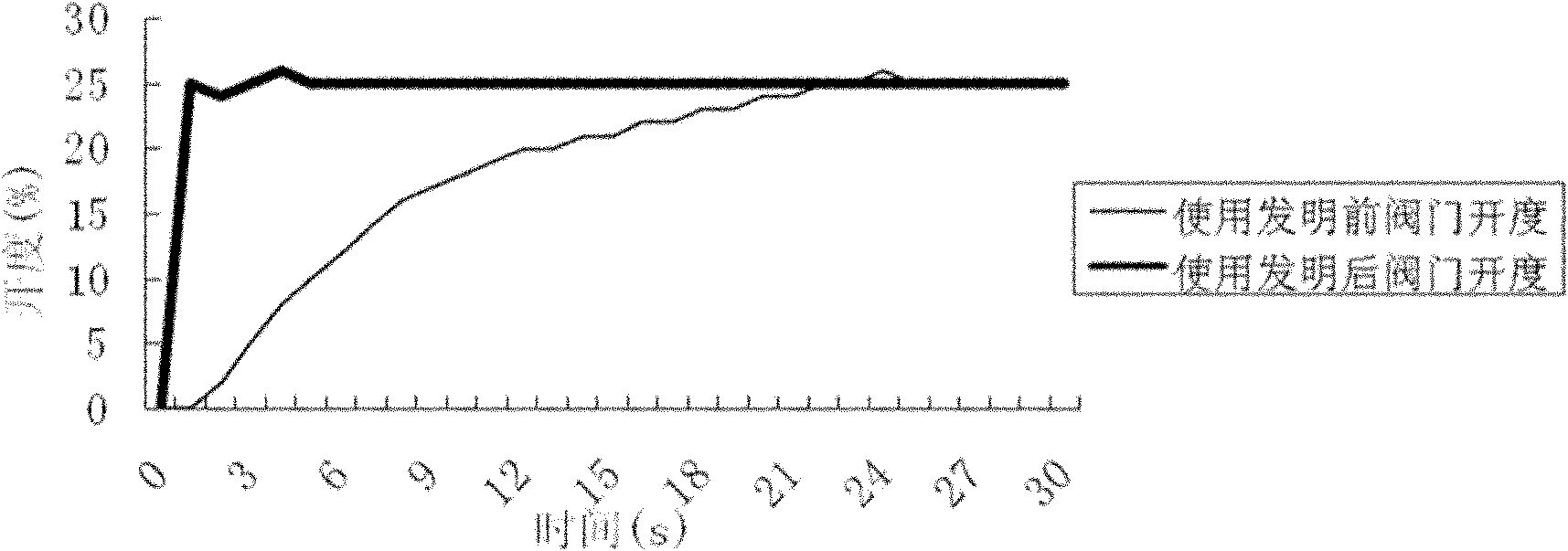

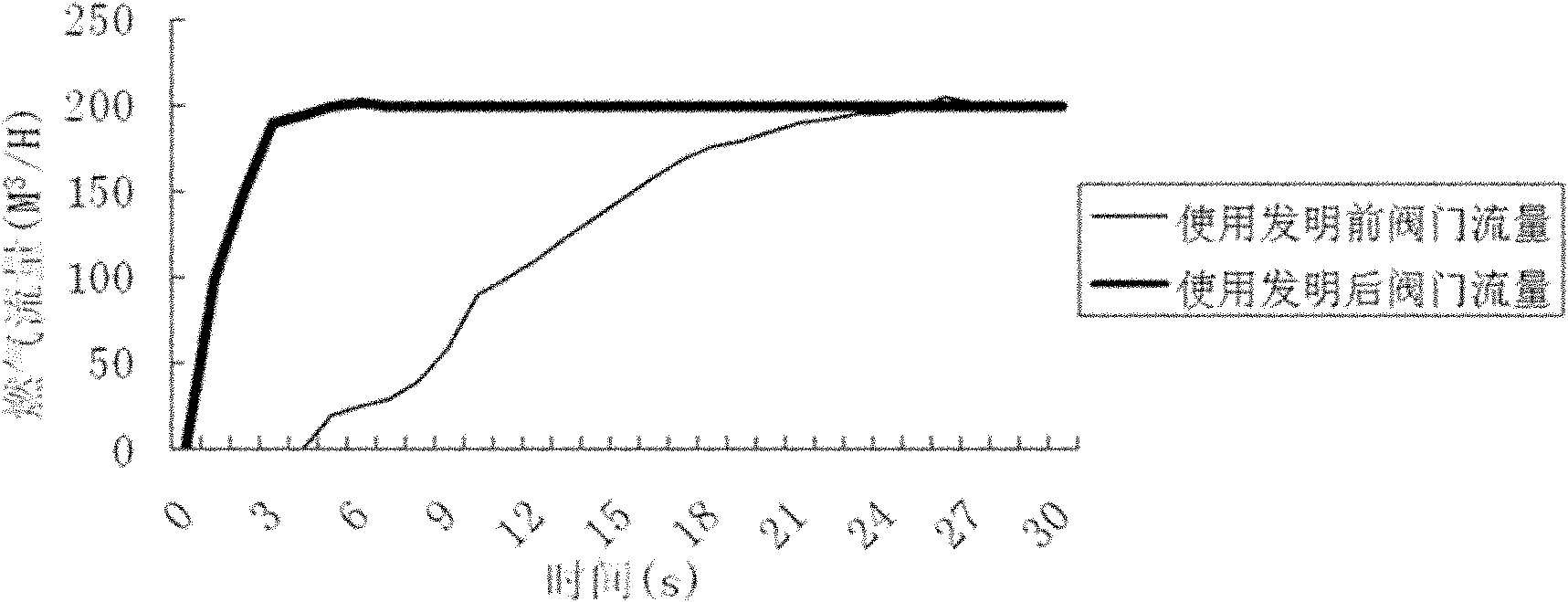

[0027] Taking the galvanized combustion system as an example, the pipe diameter of the gas flow regulating valve 4 is 100mm; the pipe diameter of the air flow regulating valve 6 is 400mm; when the temperature and pressure are stable, the opening of the gas flow regulating valve 4 and the air flow regulating valve 6 Both are 25%, the gas flow under this opening is 200M 3 / H, air flow is 800M 3 / H. Control the combustion system as follows:

[0028] A. Adjust the opening of the gas flow regulating valve 4 and the air flow regulating valve 6 to 25% before combustion, and the gas flow regulating valve 4 and the air flow regulating valve 6 in this process are controlled by the PLC control system.

[0029] B. Carry out combustion and run the PID control system 3. The PID control system 3 uses the gas flow regulating valve 4 and the air flow regulating valve 6 to increase or decrease the fuel and air flow according to the change of the load and working conditions, adjust the tempera...

Embodiment 2

[0032] Taking the combustion system in the heating section of the continuous retreat unit as an example, the diameter of the gas flow regulating valve 4 is 100mm; the pipe diameter of the air flow regulating valve 6 is 400mm; when the temperature and pressure are stable, the gas flow regulating valve 4 and the air flow regulating valve 6 The opening degree is 20%, and the gas flow rate under this opening degree is 150M 3 / H, air flow is 600M 3 / H. Control the combustion system as follows:

[0033] A. Adjust the opening of the gas flow regulating valve 4 and the air flow regulating valve 6 to 16% before combustion, which is 80% of the opening in stability. control system control.

[0034] B. Carry out combustion and run the PID control system 3. The PID control system 3 uses the gas flow regulating valve 4 and the air flow regulating valve 6 to increase or decrease the fuel and air flow according to the change of the load and working conditions, adjust the temperature and th...

Embodiment 3

[0037] Taking the combustion system in the heating section of the continuous retreat unit as an example, the diameter of the gas flow regulating valve 4 is 80mm; the pipe diameter of the air flow regulating valve 6 is 300mm; when the temperature and pressure are stable, the gas flow regulating valve 4 and the air flow regulating valve 6 The opening degree is 30%, and the gas flow rate under this opening degree is 120M 3 / H, air flow is 480M 3 / H. Control the combustion system as follows:

[0038] A. Adjust the opening of the gas flow regulating valve 4 and the air flow regulating valve 6 to 28% before combustion, which is 93.3% of the opening in stability. The gas flow regulating valve 4 and air flow regulating valve 6 in this process are passed through PLC control system control.

[0039]B. Carry out combustion and run the PID control system 3. The PID control system 3 uses the gas flow regulating valve 4 and the air flow regulating valve 6 to increase or decrease the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com