Cross-layer hollow energy transmitting fiber

An energy-transmitting optical fiber and hollow-core technology, which is applied in the field of sunlight-transmitting optical fibers, can solve the problems that optical fibers are not suitable for sunlight transmission, are expensive, and have low loss, and achieve the effect of improving the utilization level of solar energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

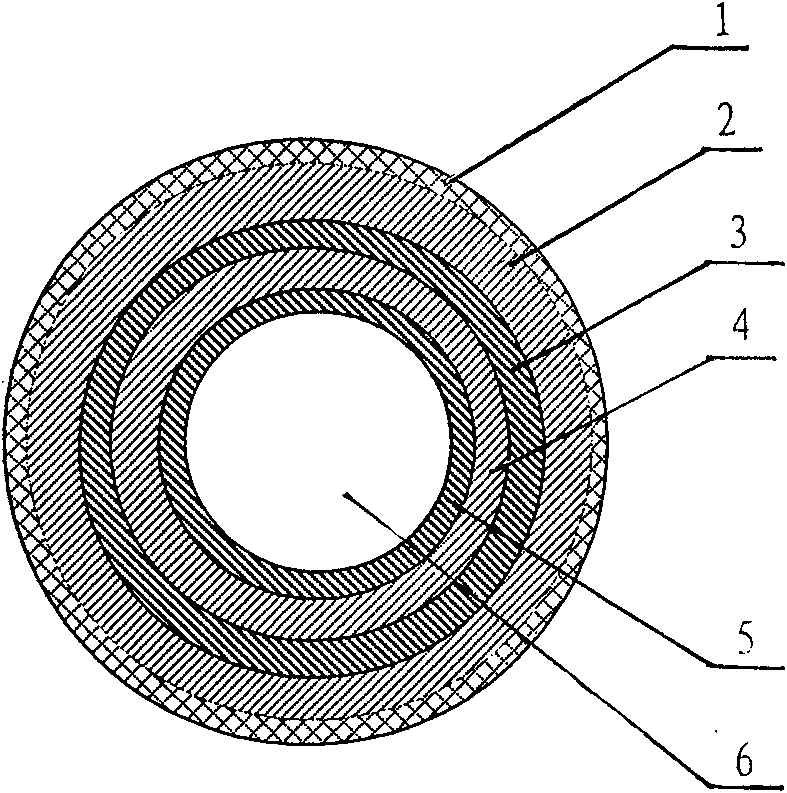

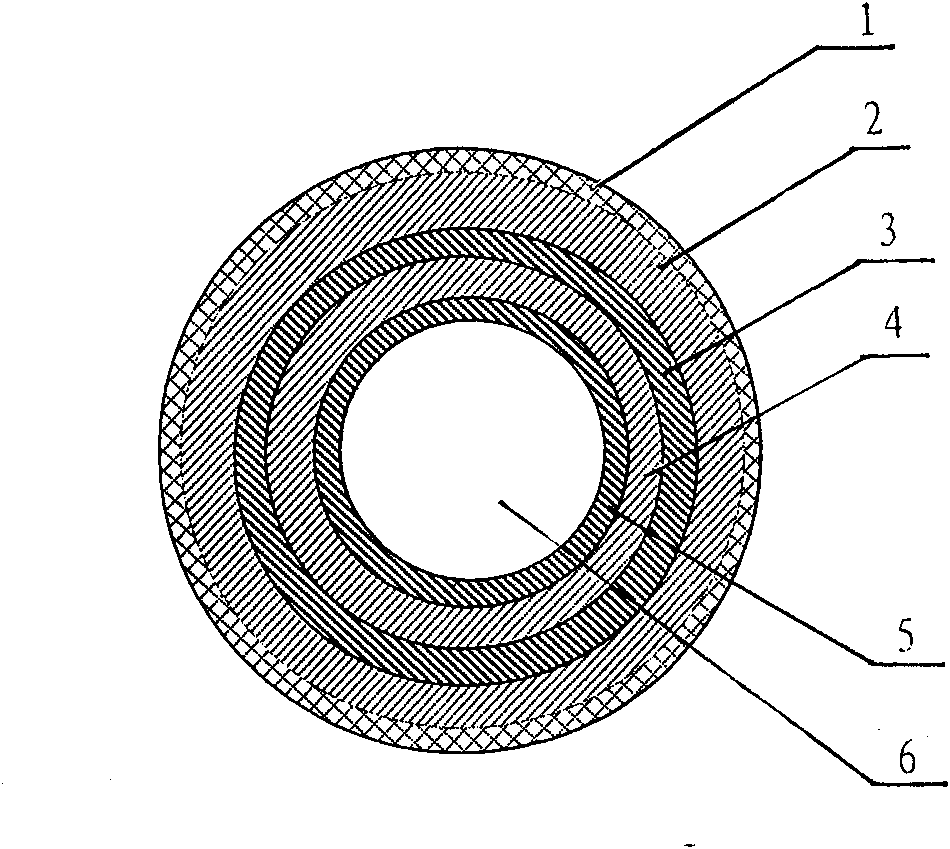

[0009] This example gives titanium dioxide (TiO 2 ) layer and polymethyl methacrylate (PMMA) interlayered hollow core fiber, the outer diameter of the PMMA tube is 7mm, and the first layer is TiO2 in the order from outside to inside 2 layer with a thickness of 15um and a refractive index of 2.4; the second layer is a PMMA layer with a thickness of 15um and a refractive index of 1.48; the third layer is TiO 2 , layer thickness 10um, refractive index 2.4; hollow core diameter 4mm, core refractive index n 0 = 1.0. The optical fiber coating is prepared by the sol-gel method. The entire preparation process is completed on a vertical optical fiber coating machine. The liquid flow rate and reaction temperature are controlled by computer operating procedures to ensure that the prepared film layer has a dense, smooth and uniform structure and good optical properties. After the required solution and cleaning solution are prepared according to the designed mixing ratio, the inner wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com