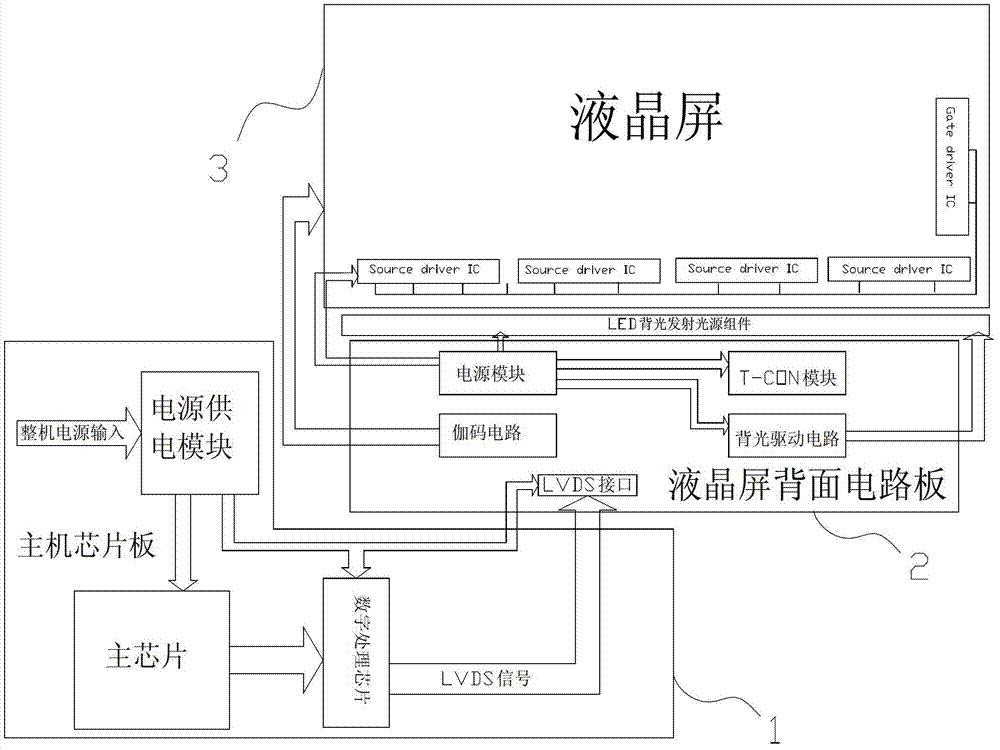

LCD panel display driving system and flexible circuit board thereof

A flexible circuit board and display drive technology, applied in the direction of nonlinear optics, static indicators, instruments, etc., can solve the problems of data transmission speed and clock frequency limitation, effective shielding, and LCD screen cannot be manufactured. Achieve the effect of increasing data transmission speed, reasonable circuit layout, and reducing electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

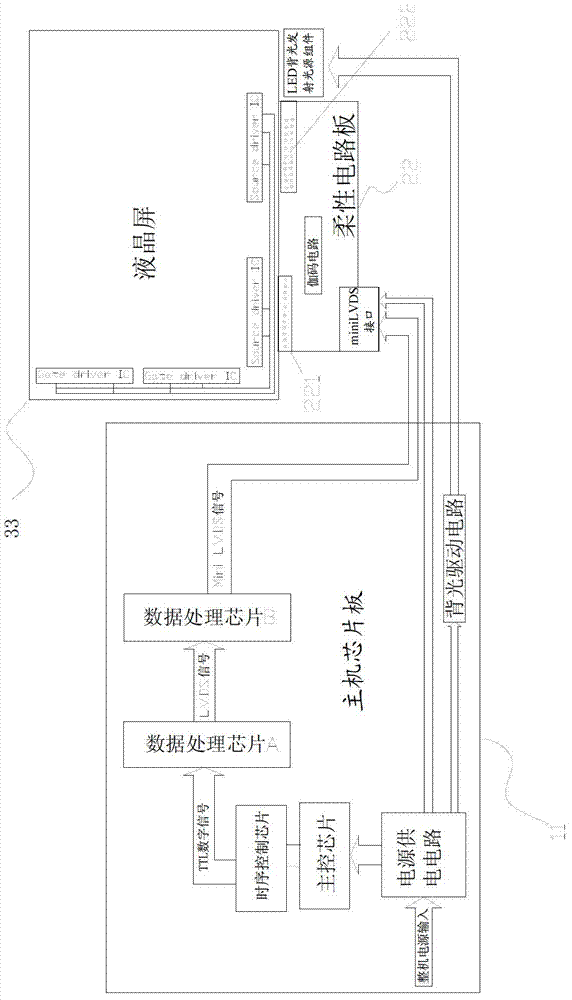

[0015] Such as figure 2 As shown, the present invention provides an embodiment of the present invention to provide a liquid crystal display drive system, including a host chip board 11, a flexible circuit board (FPC) 22, and a liquid crystal screen 33 connected in sequence; wherein the input of the flexible circuit board 22 The terminal is connected to the host chip board through the miniLVDS interface for data transmission, and the output terminal of the flexible circuit board is connected to the integrated circuit inside the LCD screen through two integrated FPC cable interfaces. A gamma circuit is also arranged in the flexible circuit board.

[0016] The host chip board is provided with a power supply circuit, a main control chip, a timing control chip, a bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com