Method for preparing pyramid-shaped lattice sandwich plate by using fiber woven cloth

A technology of fiber weaving and pyramid, which is applied in the field of preparation of composite material pyramid lattice sandwich panels, can solve the problems of overlapping of pyramid lattice sandwich panels, achieve uniform thickness of rods, enhance structural strength, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

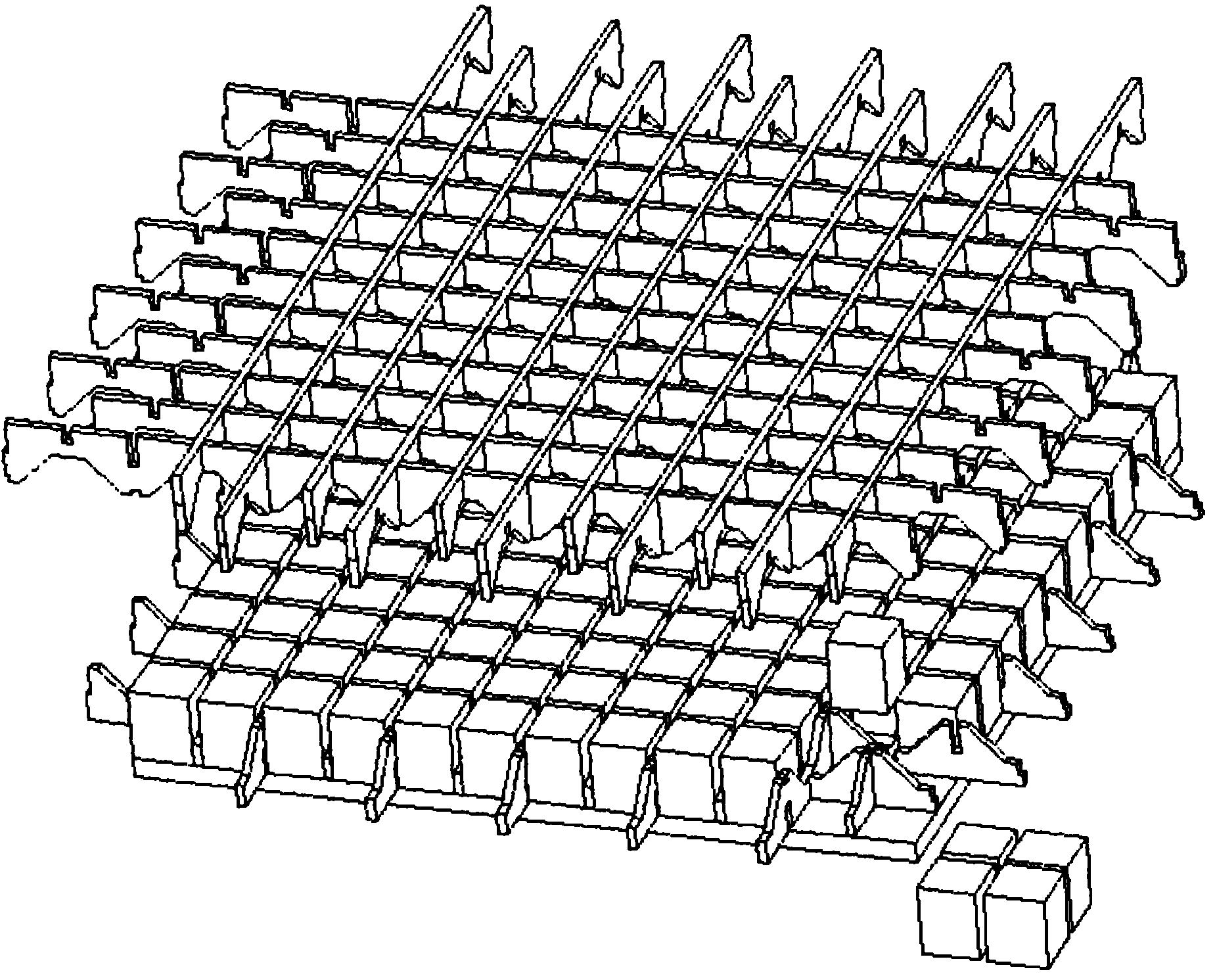

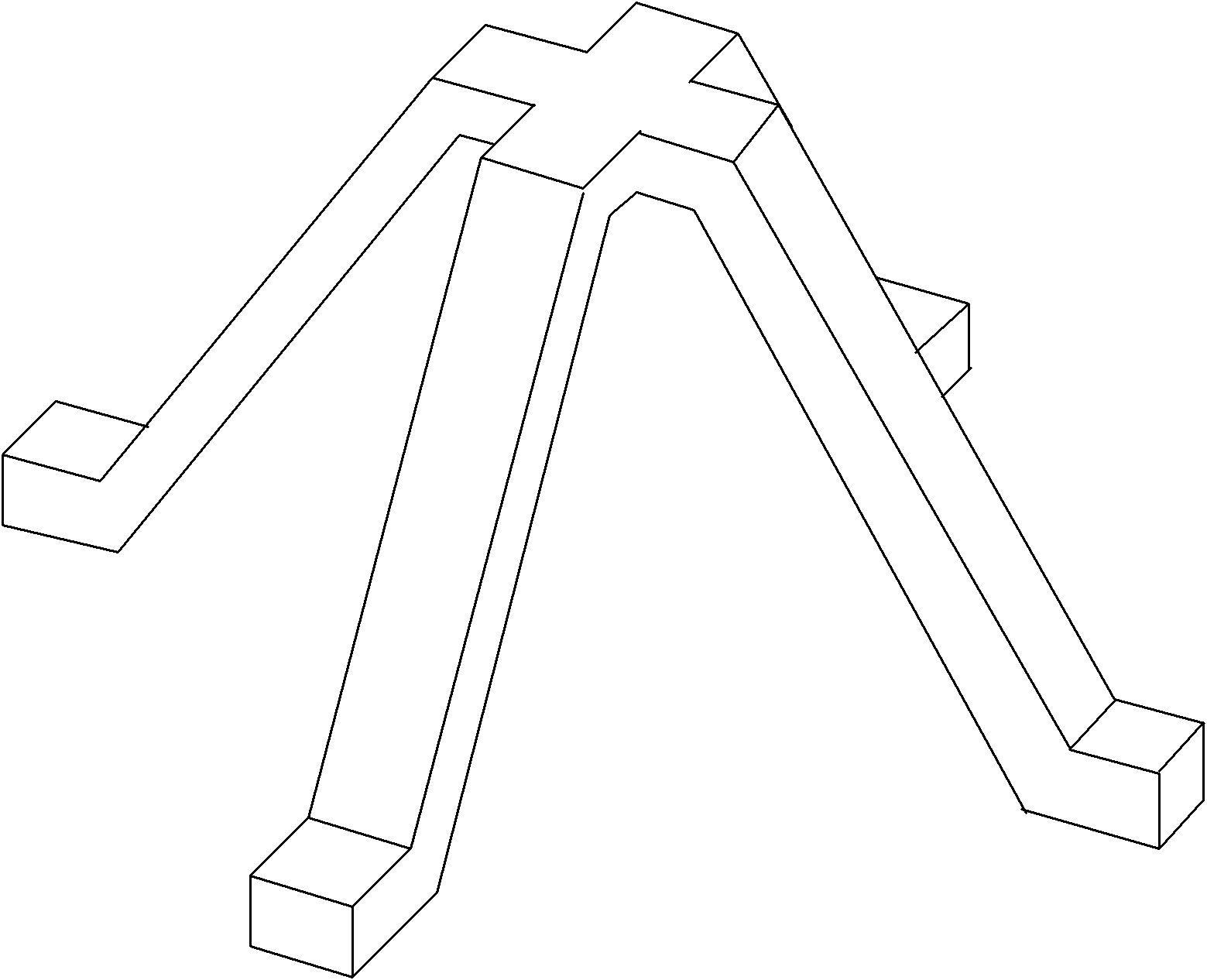

[0014] Specific embodiment one: a kind of method that adopts fiber woven cloth to prepare pyramid-shaped lattice sandwich panel, the preparation process of described composite material pyramid-shaped lattice sandwich panel is:

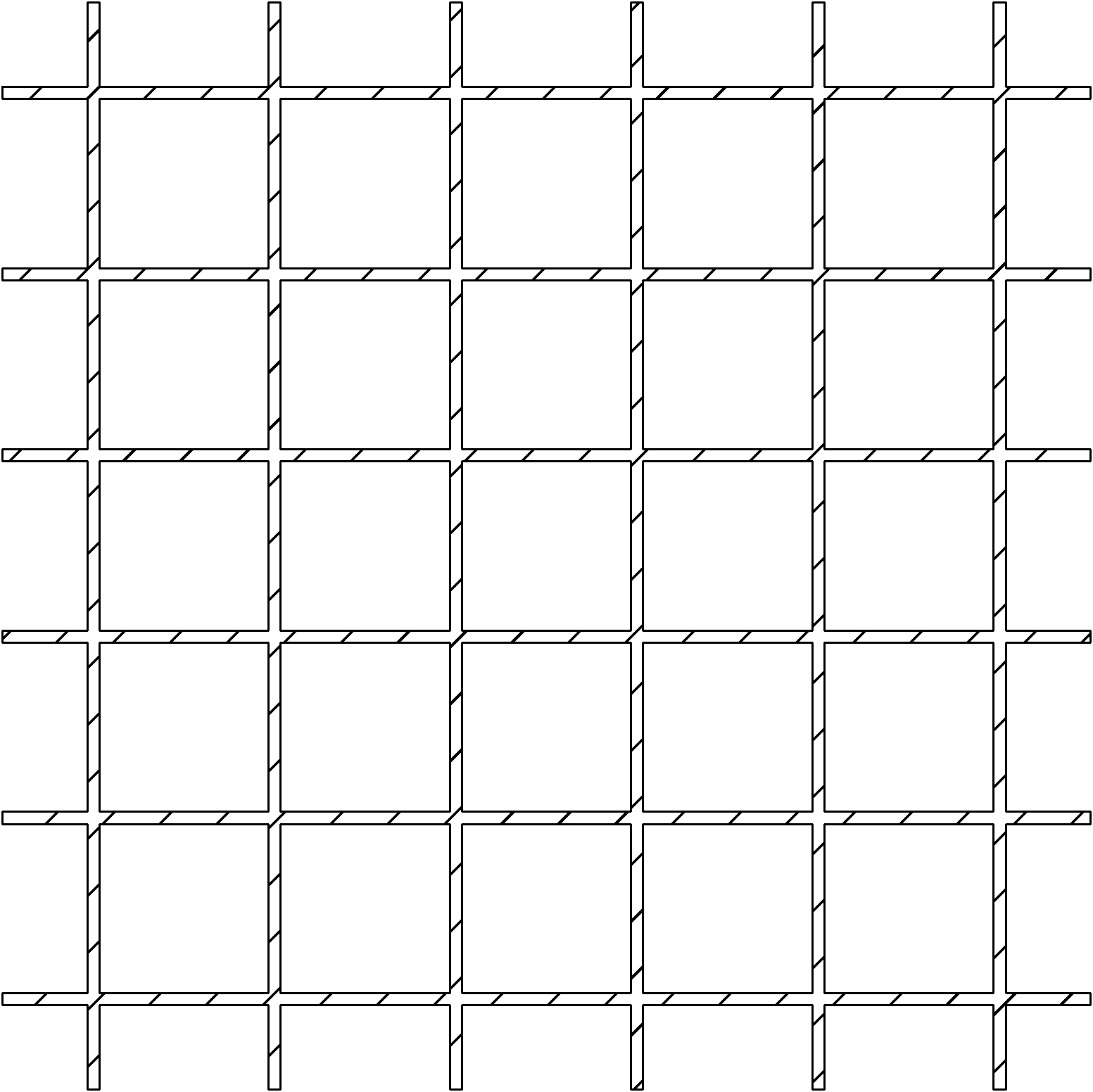

[0015] Step 1. According to the structure and size of the mold, use a cutting machine or cutting machine to cut the bidirectional fiber woven fabric into a lattice structure that can be completely nested on the mold, and the cutting direction is along the fiber direction of the woven fabric;

[0016] Step 2, using mold cleaning agent or acetone solution to clean the outer surface of the mold, and then applying the sealing agent and the mold release agent to the outer surface of the mold in sequence;

[0017] Step 3, laying the fiber woven cloth with lattice structure obtained in step 1 layer by layer in the mold treated in step 2, and fixing the mold with a clamp;

[0018] Step 4. Place the mold fixed in step 3 in a hot press to cure it. The curing tem...

specific Embodiment approach 2

[0023] Specific embodiment 2: This embodiment is a further limitation of step 4 in the method for preparing a pyramid-shaped lattice sandwich panel using fiber woven cloth described in specific embodiment 1. In step 1, the fiber woven cloth adopts the 3234 model For the epoxy resin, the curing temperature described in step 4 is 120° C., the curing pressure is 0.5 MPa, and the curing time is 1.5 hours.

[0024] The curing temperature, curing pressure and curing time described in this embodiment are set according to the composition of the fiber woven cloth described in step 1, when the fiber woven cloth described in step 1 adopts carbon fiber weaving model T700, And when the synthetic fiber woven cloth is impregnated in the epoxy resin model 3234, the curing temperature of the mold placed in the hot press for curing in step 4 is 120°C, the curing pressure is 0.5Mpa, and the curing time is 1.5 hours.

specific Embodiment approach 3

[0025] Specific embodiment three: This embodiment is a further limitation of step 4 in the method for preparing a pyramid-shaped lattice sandwich panel by using fiber woven cloth described in specific embodiment one. In step one, the fiber woven cloth adopts the TDE85 model For epoxy resin, the curing temperature described in step 4 is 175°C, the curing pressure is 0.5Mpa, and the curing time is 3 hours.

[0026] The curing temperature, curing pressure and curing time described in this embodiment are set according to the composition of the fiber woven cloth described in step 1, when the fiber woven cloth described in step 1 adopts carbon fiber weaving model T700, And when the synthetic fiber woven cloth is impregnated in the TDE85 type epoxy resin, the curing temperature of the mold placed in the hot press for curing in step 4 is 175°C, the curing pressure is 0.5Mpa, and the curing time is 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com