Auxiliary dedusting device and method of thermal power plant coal conveying system

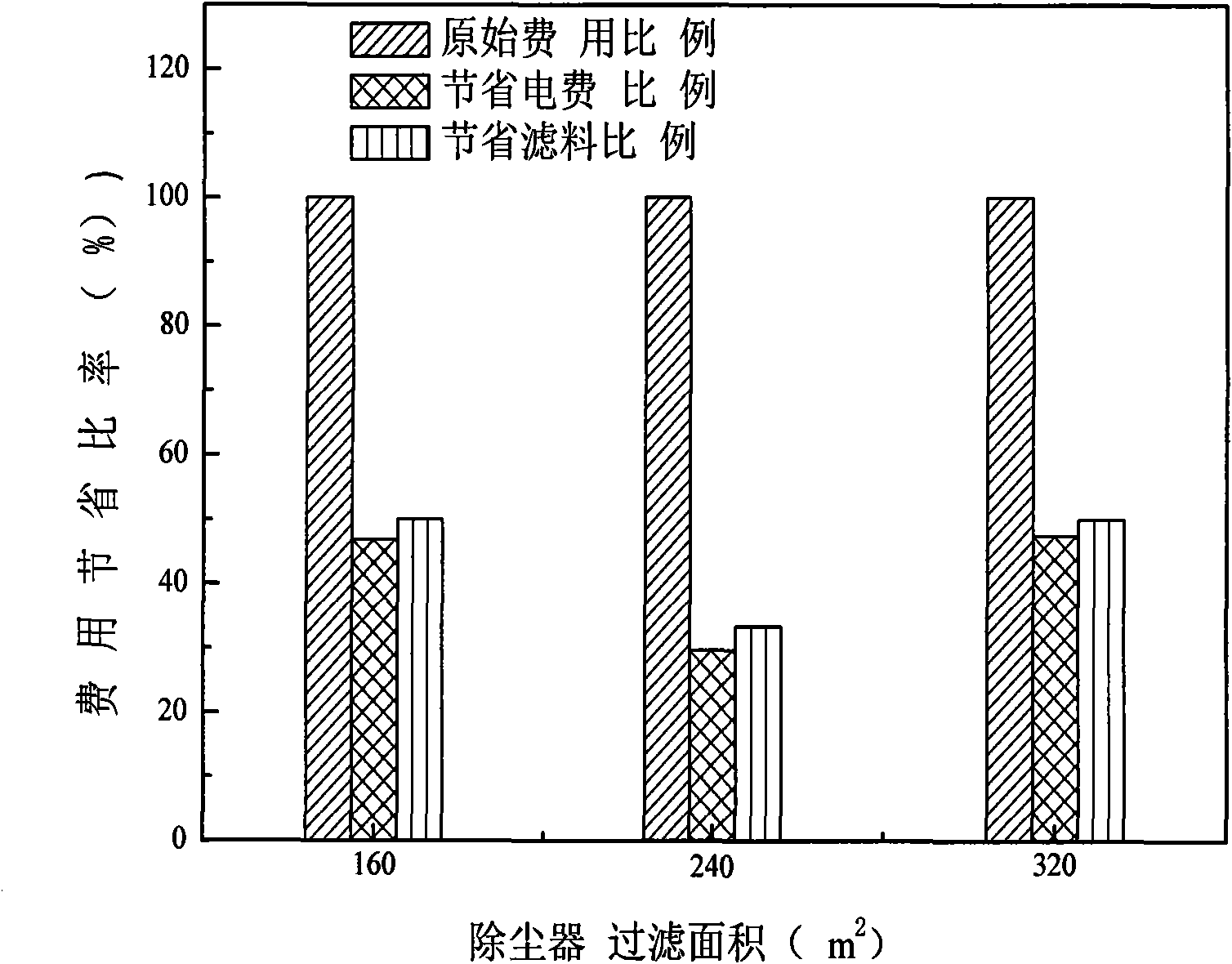

A technology of coal conveying system and dust removal device, which is applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of large dust removal air volume of dust collector, large initial investment capital, and high cost of dust removal equipment, so as to reduce operation and civil construction costs, reduce The effect of initial investment and reduction of civil construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An auxiliary dedusting device for a coal handling system in a thermal power plant, the auxiliary dedusting device is a bypass pipe, and the bypass pipe connects the upper negative pressure area and the lower positive pressure area in the coal falling pipeline of the power plant coal handling system , so that the positive pressure zone at the lower part of the coal falling pipeline is exhausted, and the exhausted gas passes through the bypass pipe to supplement the negative pressure zone at the upper part of the coal falling pipeline.

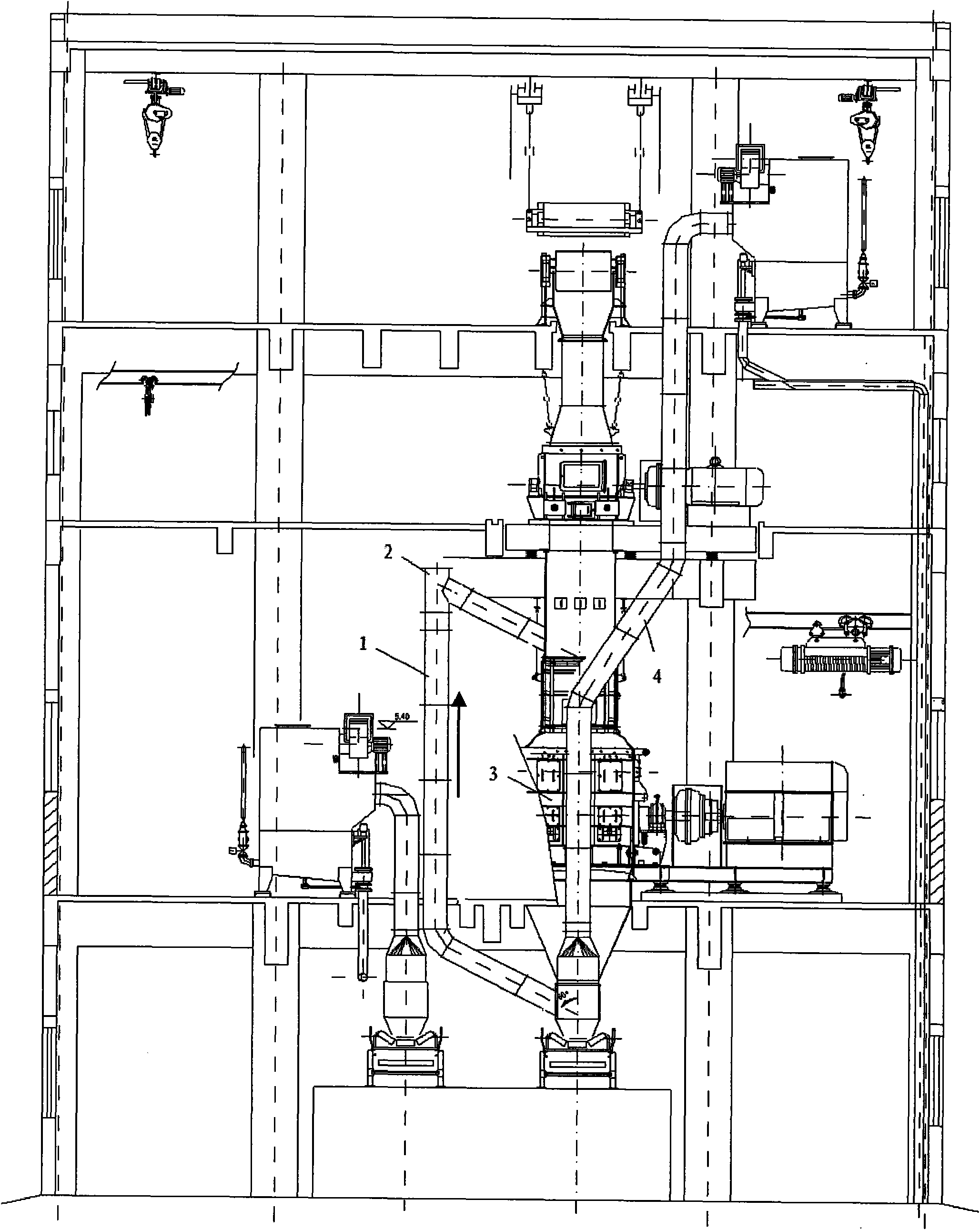

[0032] Specifically, such as figure 1 As shown, the upper negative pressure zone of the coal falling pipeline is the coal falling pipe on the upper part of the coal crusher 3 in the coal conveying system of the power plant, and the lower positive pressure zone of the coal falling pipeline is the lower part of the coal crusher 3 Coal drop pipe. During specific implementation, holes are opened on the coal drop pipe on the upper part of the...

Embodiment 2

[0047] The embodiment of the present invention also provides a dust removal method for the coal conveying system of a thermal power plant. The method is to perform positive pressure exhaust at the lower part and negative pressure gas supply at the upper part of the coal falling pipeline with pressure difference in the coal conveying system of the power plant.

[0048] Specifically, see figure 1 , the coal drop pipeline with pressure difference is the coal drop pipe at the upper part of the coal crusher and the coal drop pipe at the lower part of the coal crusher in the coal conveying system of the power plant. The coal drop pipe on the upper part of the coal machine is connected with the coal drop pipe on the lower part of the coal crusher.

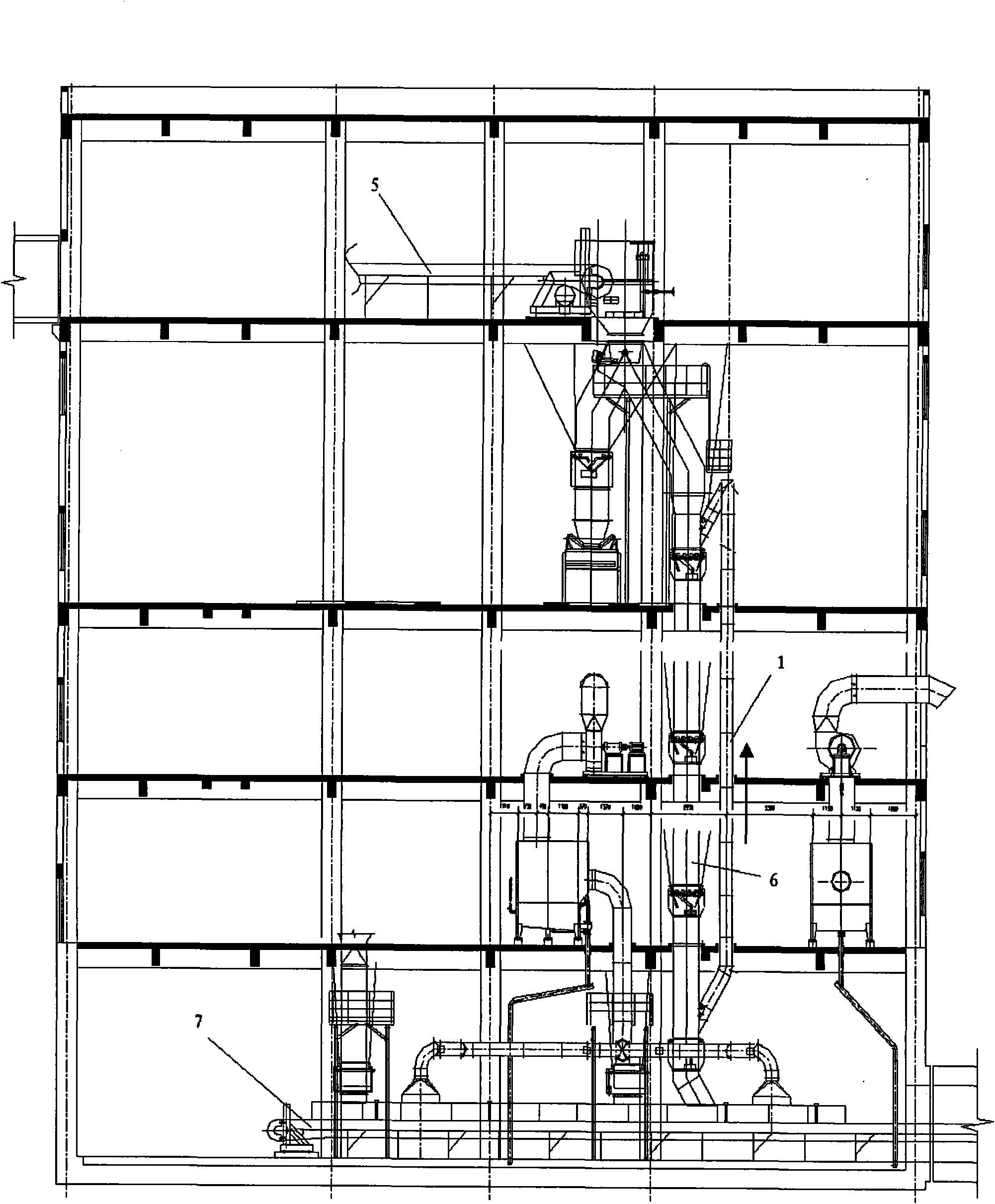

[0049] Specifically, see figure 2 , the coal-falling pipeline with pressure difference is the coal-falling pipe of the uppermost belt and the coal-falling pipe of the lowermost belt of the transfer station in the coal transportation sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com