Method for recycling waste concrete broken fine particles

A technology of waste concrete and fine particles, which is applied in the field of building materials production, can solve the problems of low added value of recycled products and high cost of recycling waste concrete, and achieve the goals of reducing mold collapse, improving the strength of aerated concrete, and increasing the alkali content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

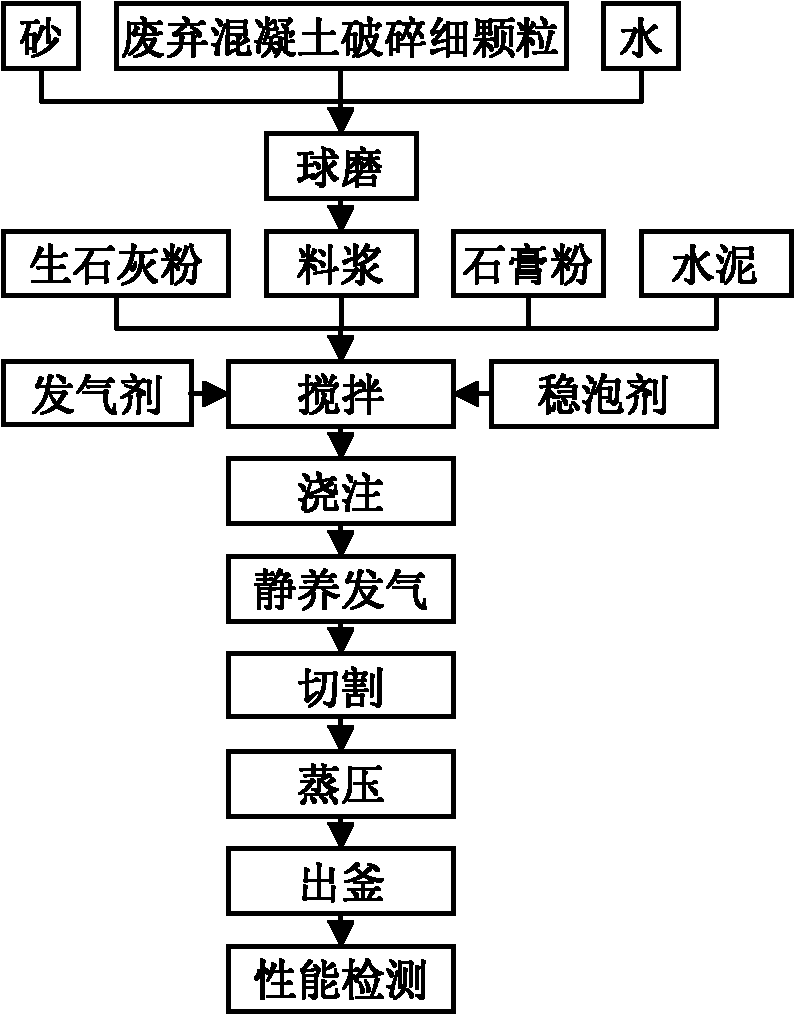

Method used

Image

Examples

Embodiment 1~5

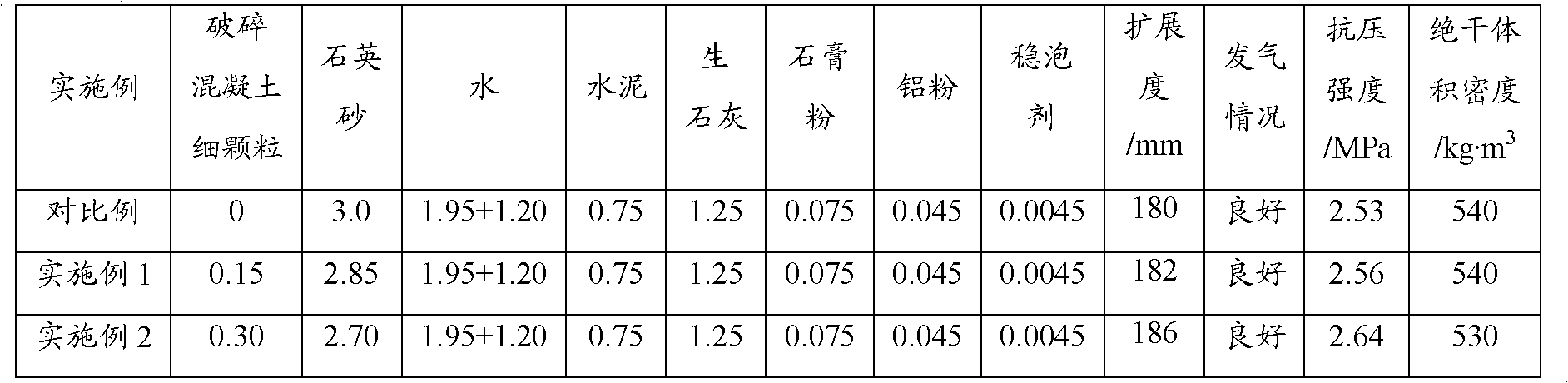

[0018] The waste concrete obtained after scientific research and testing in the laboratory is used, and the fine aggregate is natural river sand. The waste concrete is first crushed by the jaw crusher, and then sieved into recycled aggregate with a particle size above 2.5mm and crushed fine particles below 2.5mm. River sand is used as the main raw material for sand entrainment. Quicklime, aluminum powder, gypsum, and tea saponin foam stabilizers are all obtained from Hangzhou Aerated Concrete Plant. Cement is purchased from Qianchao Cement Plant with a strength grade of 42.5.

[0019] The design strength and density grades of air-entrained concrete are A2.5 and B05. First, waste concrete crushed fine particles, quartz sand and water are added to the ball mill according to the proportions in Examples 1 to 3 in Table 1, and ball milled for 2 hours, wherein the water consumption is the water consumption before "+" in Table 1, and the slurry obtained by ball milling Add cement, q...

Embodiment 3~5

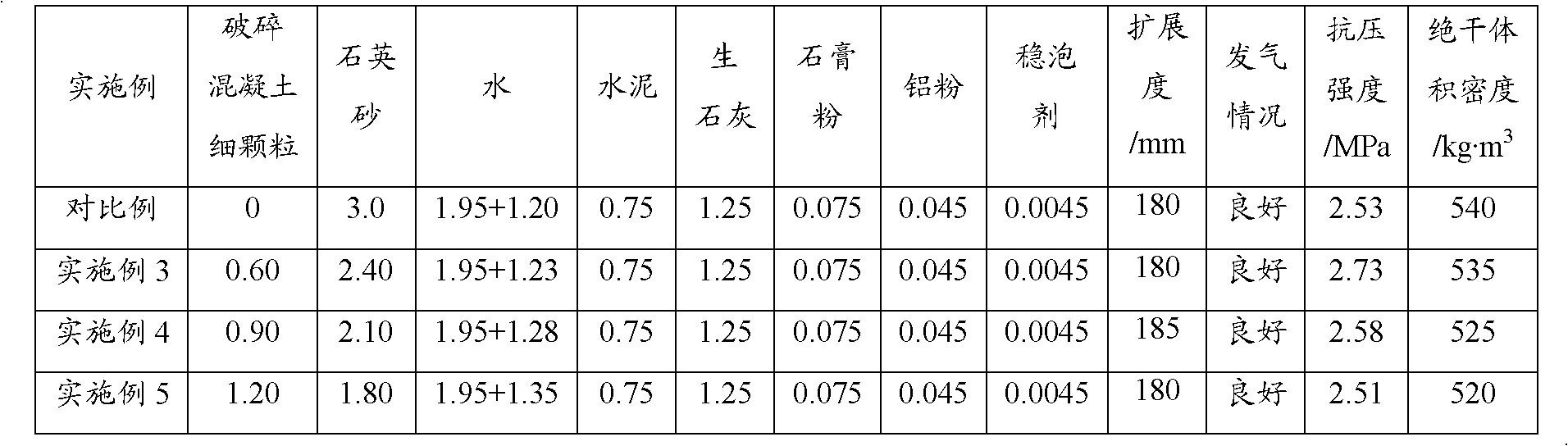

[0024] The waste concrete obtained after scientific research and testing in the laboratory is used, and the fine aggregate is natural river sand. The waste concrete is first crushed by the jaw crusher, and then sieved into recycled aggregate with a particle size above 2.5mm and crushed fine particles below 2.5mm. River sand is used as the main raw material for sand entrainment. Quicklime, aluminum powder, gypsum, and tea saponin foam stabilizers are all obtained from Hangzhou Aerated Concrete Plant. Cement is purchased from Qianchao Cement Plant with a strength grade of 42.5.

[0025] The design strength and density grades of air-entrained concrete are A2.5 and B05. First, waste concrete crushed fine particles, quartz sand and water are added to the ball mill according to the proportions in Examples 6 to 8 in Table 2, and ball milled for 1 hour, wherein the water consumption is the water consumption before "+" in Table 2, and the slurry obtained by ball milling Add cement, qu...

Embodiment 6~10

[0030] The waste concrete obtained after scientific research and testing in the laboratory is used, and the fine aggregate is natural river sand. The waste concrete is first crushed by the jaw crusher, and then sieved into recycled aggregate with a particle size above 2.5mm and crushed fine particles below 2.5mm. River sand is used as the main raw material for sand entrainment. Quicklime, aluminum powder, gypsum, and tea saponin foam stabilizers are all obtained from Hangzhou Aerated Concrete Plant. Cement is purchased from Qianchao Cement Plant with a strength grade of 42.5.

[0031] The design strength and density grades of air-entrained concrete are A3.5 and B06. First, waste concrete crushed fine particles, quartz sand and water are added to the ball mill according to the proportions in Examples 6 to 10 in Table 3, and ball milled for 3 hours, wherein the water consumption is the water consumption before "+" in Table 3, and the slurry obtained by ball milling Add cement, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com