Preparation method of C.I.P.Y180 pigment

A pigment and dispersion technology, applied in disazo dyes and other directions, can solve the problems of increased use of inorganic phosphates, insufficient environmental protection of waste water nutrition, and increased cost of isobutanol, and achieves improved tinting strength, bright and bright colors, dripping long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

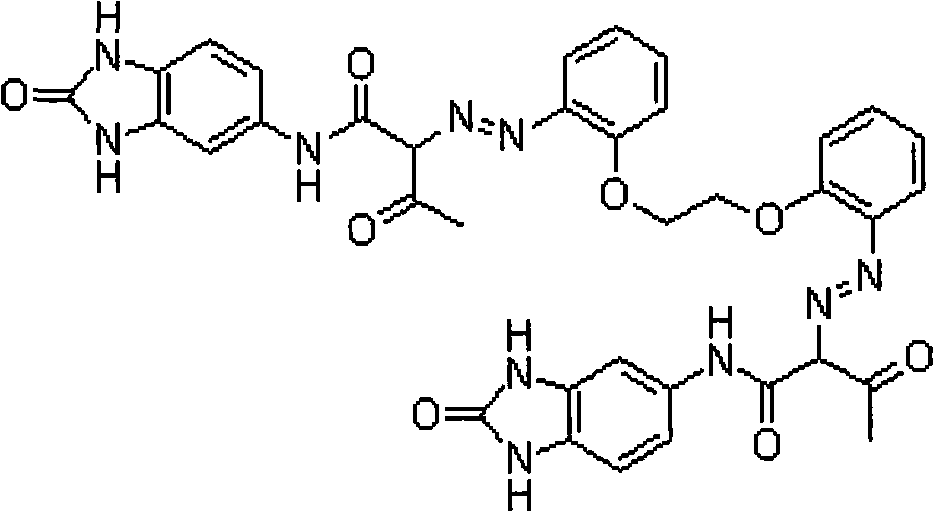

Image

Examples

example 1

[0016] Take 18.9 grams of BAPE, add 500ml of water, add 40g of HCl (35%) after dispersion, heat up to 60°C to dissolve it, then cool to 0°C, add NaNO dropwise 2 (30%) to a slight excess. After stirring for half an hour, add urea to remove excess NaNO2, add 5% activated carbon for decolorization for 1 hour, filter, and refrigerate the filtrate for later use.

[0017] Take 44 grams of AABI, add it to 500 ml of water, add 3.5 grams of SPAN-20, add 12 g of NaOH to dissolve after dispersion, and then filter to obtain a coupling component solution. After cooling the solution to 15 degrees Celsius, add acetic acid to precipitate, make PH = 6. and keep the system stable at 15 degrees Celsius;

[0018] Add the diazonium salt to the coupling suspension within 5 hours, continue to stir for 1 hour, raise the temperature to 95° C., keep warm for 1 hour, filter and wash to obtain the crude pigment.

[0019] Disperse the crude product obtained above with water at a ratio of 1:20, add 2.0 g...

example 2

[0021] Take 18.9 grams of BAPE, add 500ml of water, add 40g of HCl (35%) after dispersion, heat up to 60°C to dissolve it, then cool to 0°C, add NaNO dropwise 2 (30%) to a slight excess. After stirring for half an hour, add urea to remove excess NaNO2, add 5% activated carbon for decolorization for 1 hour, filter, and refrigerate the filtrate for later use.

[0022] Take 44 grams of AABI, add it to 500 ml of water, add 5.0 grams of SPAN-60, add 12 g of NaOH to dissolve after dispersion, and then filter to obtain a coupling component solution. After cooling the solution to 10 degrees Celsius, add acetic acid to precipitate, make PH = 6.0 and keep the system stable at 10 degrees Celsius;

[0023] Add the diazonium salt to the coupling suspension within 8 hours, continue to stir for 1 hour, raise the temperature to 90° C., keep warm for 1 hour, filter and wash to obtain the crude pigment.

[0024] Disperse the crude product obtained above with water at a ratio of 1:40, then add...

example 3

[0026] Take 18.9 grams of BAPE, add 500ml of water, add 40g of HCl (35%) after dispersion, heat up to 60°C to dissolve it, then cool to 0°C, add NaNO dropwise 2 (30%) to a slight excess. After stirring for half an hour, add urea to remove excess NaNO2, add 5% activated carbon for decolorization for 1 hour, filter, and refrigerate the filtrate for later use.

[0027] Take 44 grams of AABI, add it to 500 ml of water, add 4.0 grams of SPAN-80, add 12 g of NaOH to dissolve after dispersion, and then filter to obtain a coupling component solution. After cooling the solution to 12 degrees Celsius, add acetic acid to precipitate, make PH = 6.0 and keep the system stable at 12 degrees Celsius;

[0028] Add the diazonium salt to the coupling suspension within 6 hours, continue to stir for 1 hour, raise the temperature to 95° C., keep warm for 1 hour, filter and wash to obtain the crude pigment.

[0029] Disperse the crude product and water obtained above at a ratio of 1:20, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com