Composite tube air preheater

An air preheater and composite pipe technology, applied in the field of heat exchange, can solve the problems of unstable air excess coefficient, frequent replacement of heat storage body, poor gas-air heat transfer effect, etc. Improved service life and shorter payback period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

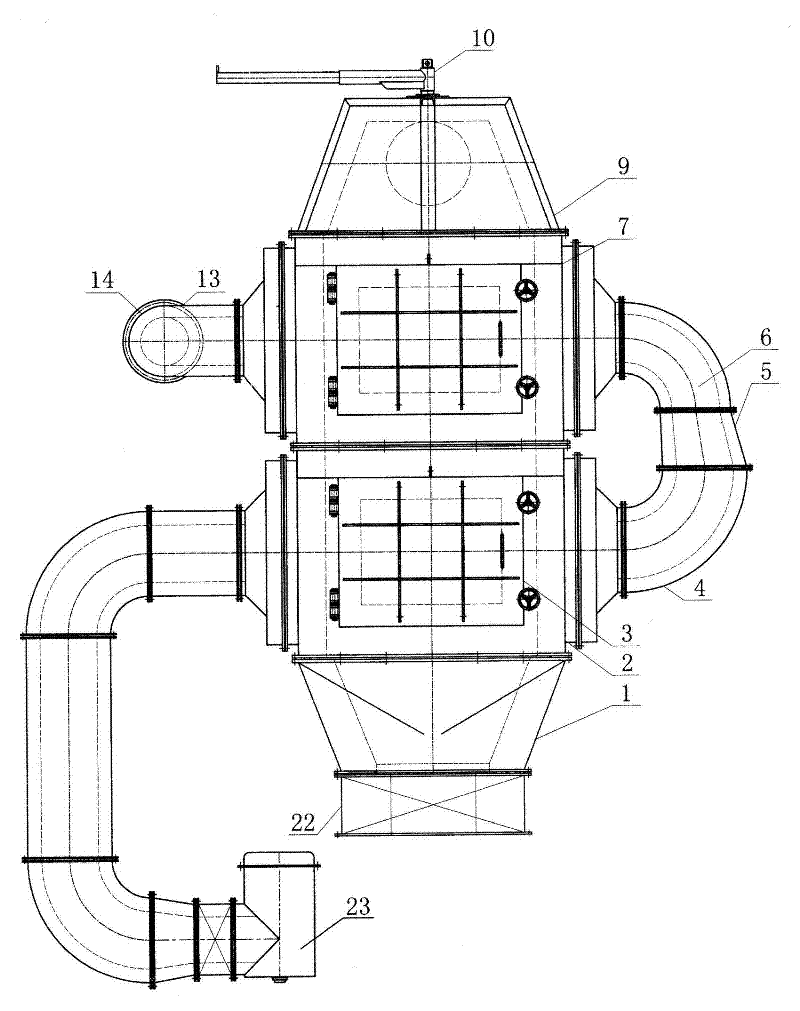

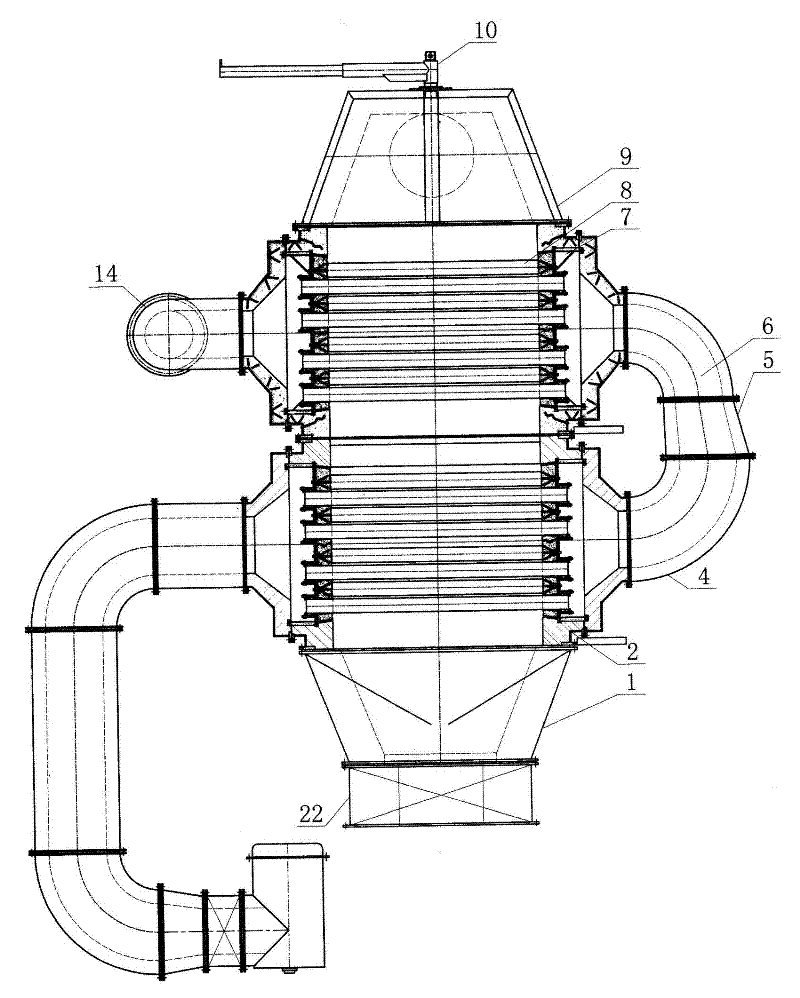

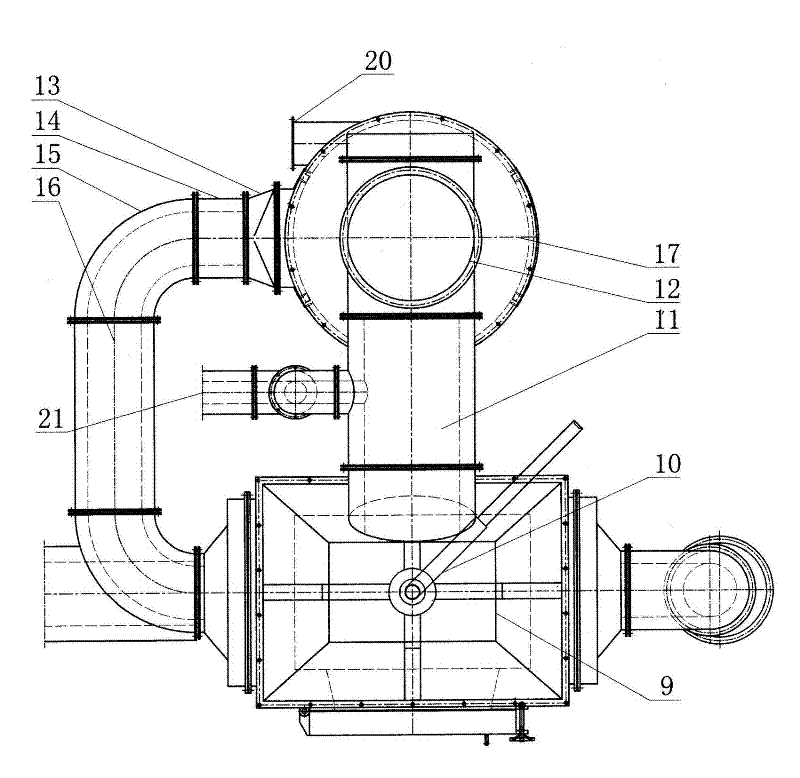

[0032] Depend on Figures 1 to 4 It can be seen that the utility model is made of a preheating box composed of silicon carbide tubes 8 as the inlet end channel of high-temperature flue gas, and the metal tube type preheating box 17 is used as the outlet end channel of high-temperature flue gas, and then the high-temperature smoke pipe And the joint is connected in series with the preheating box composed of silicon carbide tube 8 and the metal tube type preheating box 17 to discharge the flue gas after cooling;

[0033] The metal tubular preheating box 17 is used as the inlet channel of the combustion air of the burner, and the preheating box composed of silicon carbide tubes 8 is used as the outlet channel of the combustion air. The metal tubes are connected in series by high-temperature air pipes and high-temperature joints. Type preheating box body 17 and silicon carbide tube preheating box body will discharge combustion-supporting air after preheating;

[0034] The silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com