Biomass direct-fired furnace

A direct-fired furnace and biomass technology, applied in the direction of combustion methods, combustion equipment, household stoves/stoves, etc., can solve the problems of short combustion time, waste of resources, unsustainable combustion, etc., and achieve good firepower regulation performance and smoke emission Less, full burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

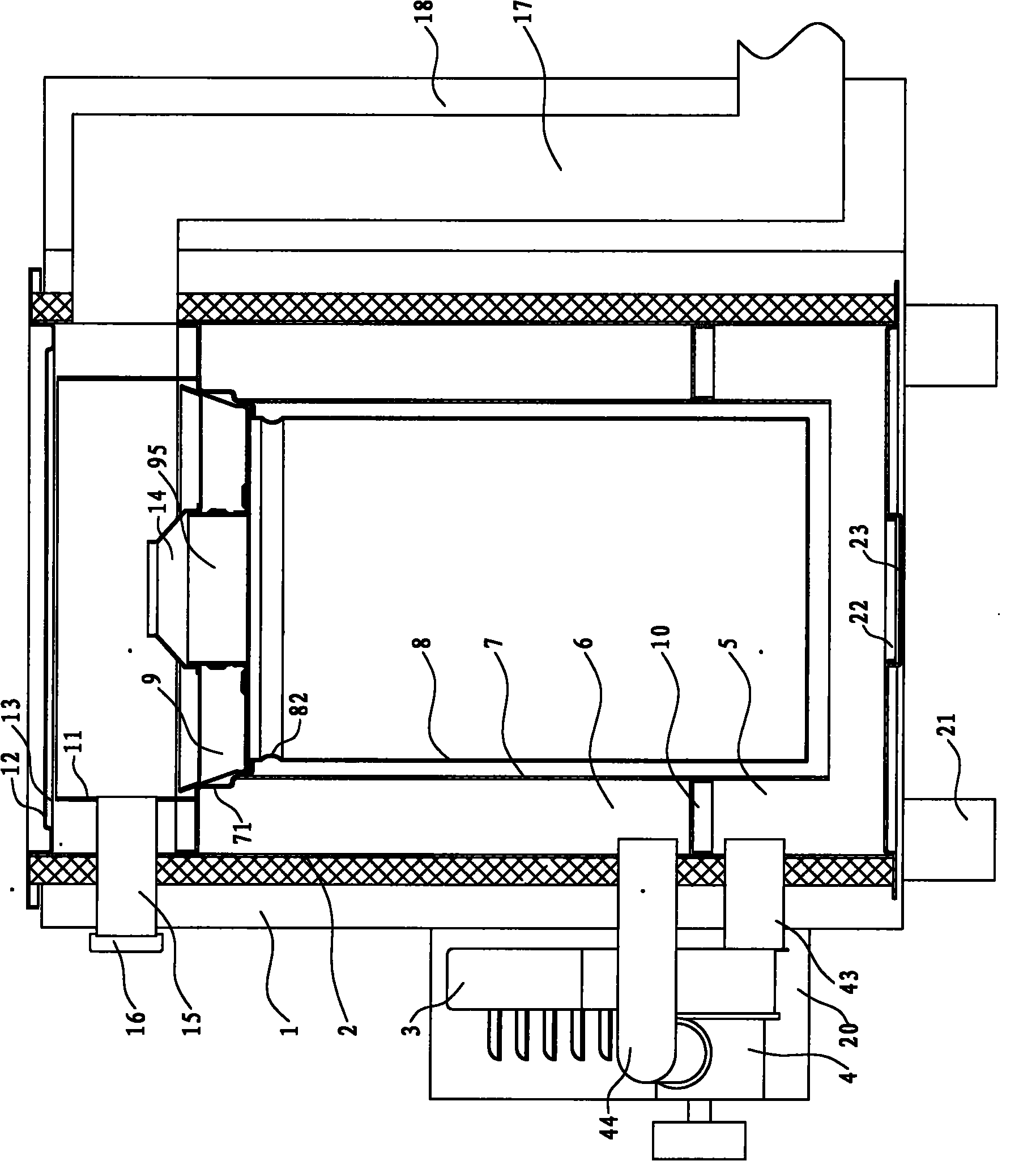

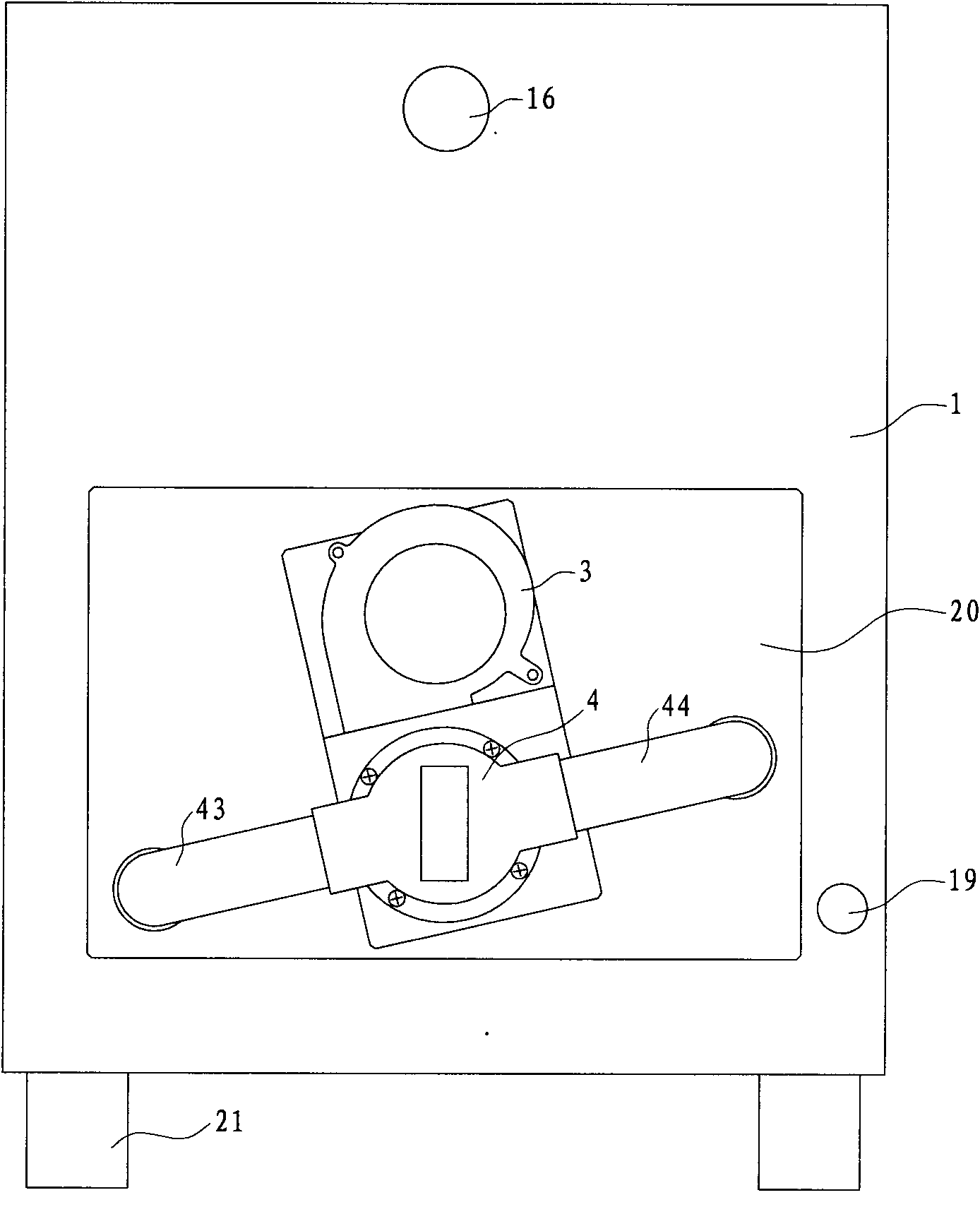

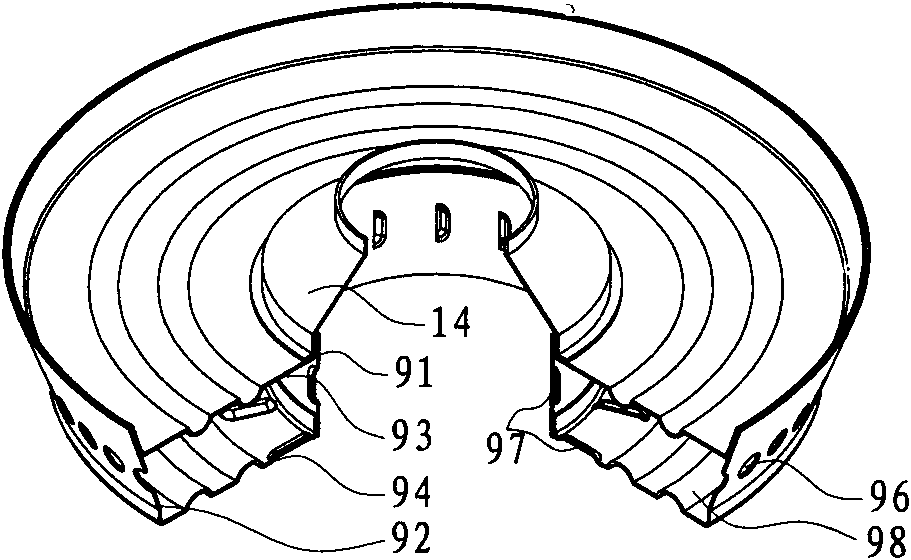

[0024] Example one, biomass direct burning furnace such as figure 1 As shown, it includes a rectangular shell 1 with a cylindrical furnace body 2 inside. The outer wall of the furnace body 2 is covered with thermal insulation materials that can reduce heat loss. The inner wall of the furnace body 2 is fixed with upper large and lower cylinders. The inner cylinder 7, the barrel-shaped material cylinder 8 is hung and placed on the ring support of the inner cylinder 7 through the upper flange 83. The inside of the material cylinder 8 is placed with biomass fuel, and the bottom wall of the material cylinder 8 has several materials. Cylinder air inlet 81, such as Figure 4 Shown; the upper end of the side wall of the barrel 8 has a convex ring 82 protruding inward, which is convenient for removing the barrel 8 or placing it in the inner barrel 7 with a tool. The ring-shaped partition 10 divides the space formed by the furnace body 2, the inner tube 7 and the material tube 8 into a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com