Longhole axis straightness measuring device based on self correction and measurement method thereof

A measuring device and self-calibration technology, which are applied to the measuring device of the straightness of the deep hole axis and the measuring field of the straightness of the deep hole, can solve the problems of the measuring object being affected by the large size of the hardware, the low measuring accuracy and the cumbersome measuring equipment, etc. Save measurement time, large measurement range, and good ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in further detail below in conjunction with accompanying drawing:

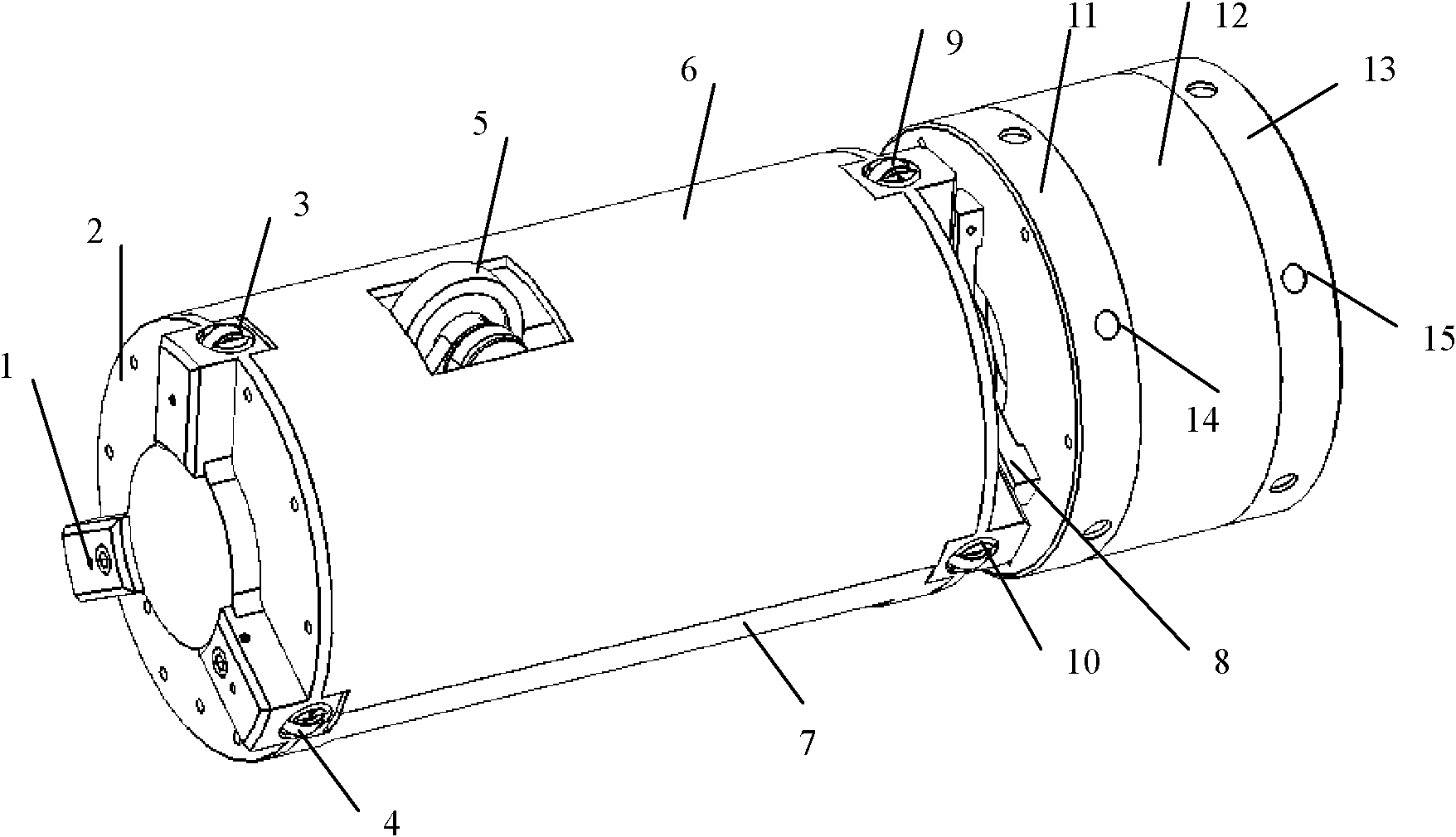

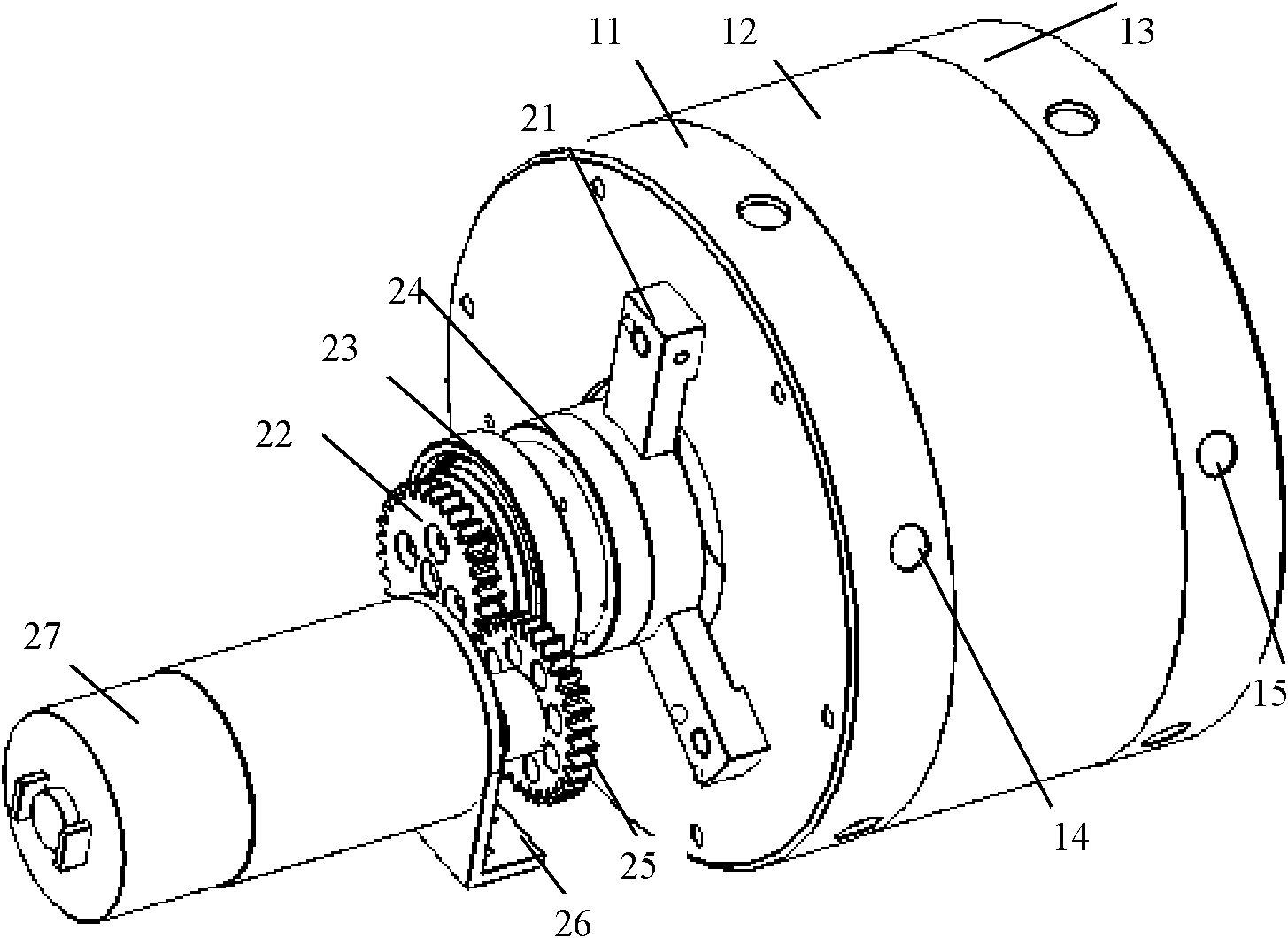

[0038] figure 1 It is a structural schematic diagram of the deep hole axis straightness measuring device based on self-calibration of the present invention, which includes a cylindrical traveling mechanism 32 and a self-centering rotating mechanism 33 arranged at the front end of the traveling mechanism 32 (see Image 6 ). The specific structures of the running gear 32 and the self-centering rotating mechanism 33 are introduced in detail respectively below:

[0039] Walking mechanism 32

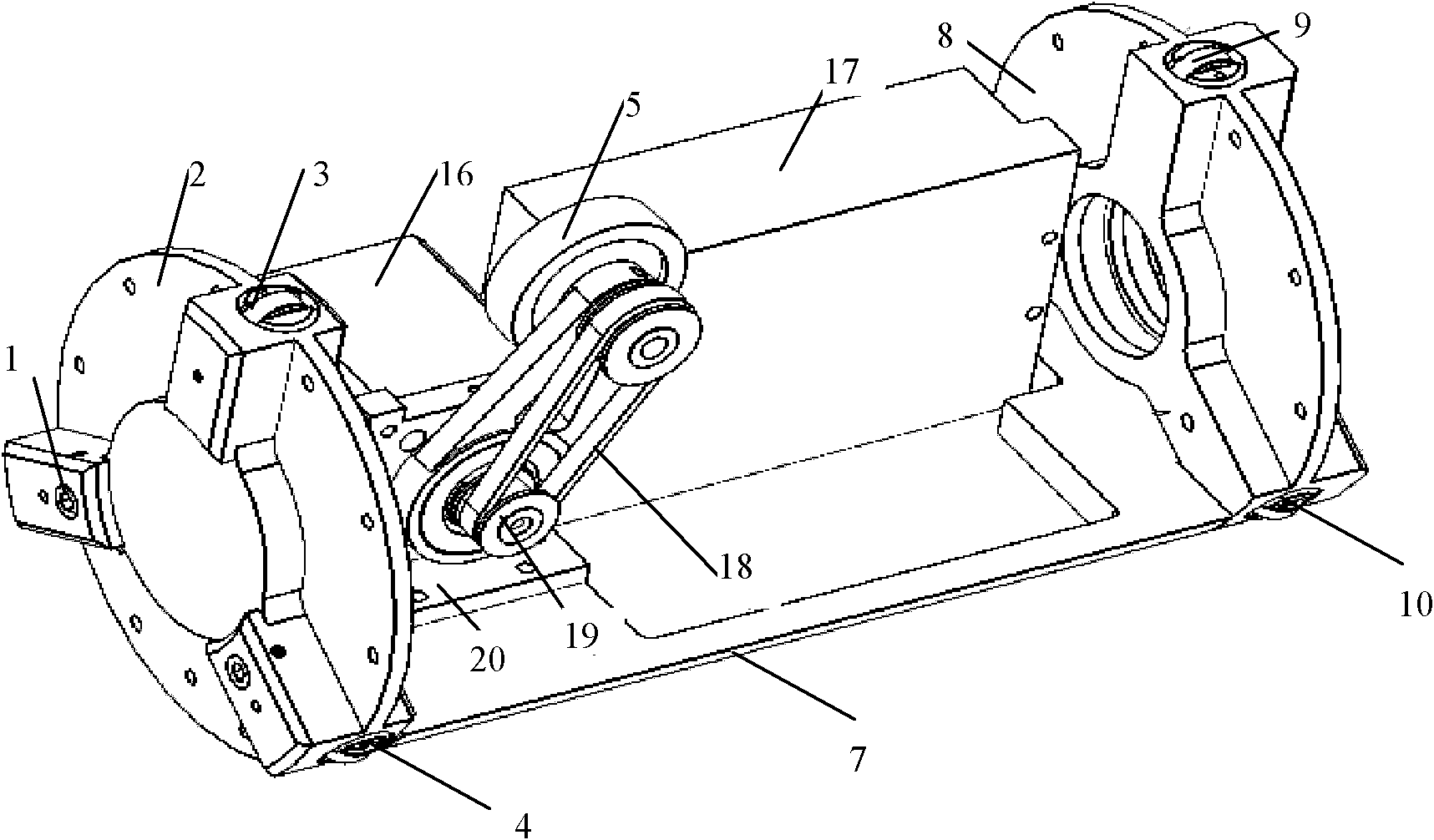

[0040] see figure 2, the running mechanism 32 includes a base 7 and front and rear wheel hubs 8,2 which are respectively arranged at two ends of the base 7, and the outer peripheral edges of the front and rear wheel hubs 8,2 are evenly distributed with radially outward adjustable rolling supports mechanism, in a preferred solution of the present invention, three sets of adjustabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com