Low-temperature physical property measuring device of solid material

A technology for measuring devices and solid materials, applied in the directions of measuring devices, material thermal development, measuring electrical variables, etc., can solve the problems of high cost, large consumption of liquid nitrogen, and high requirements for supporting equipment, and achieve stable and durable low temperature environment and easy disassembly , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

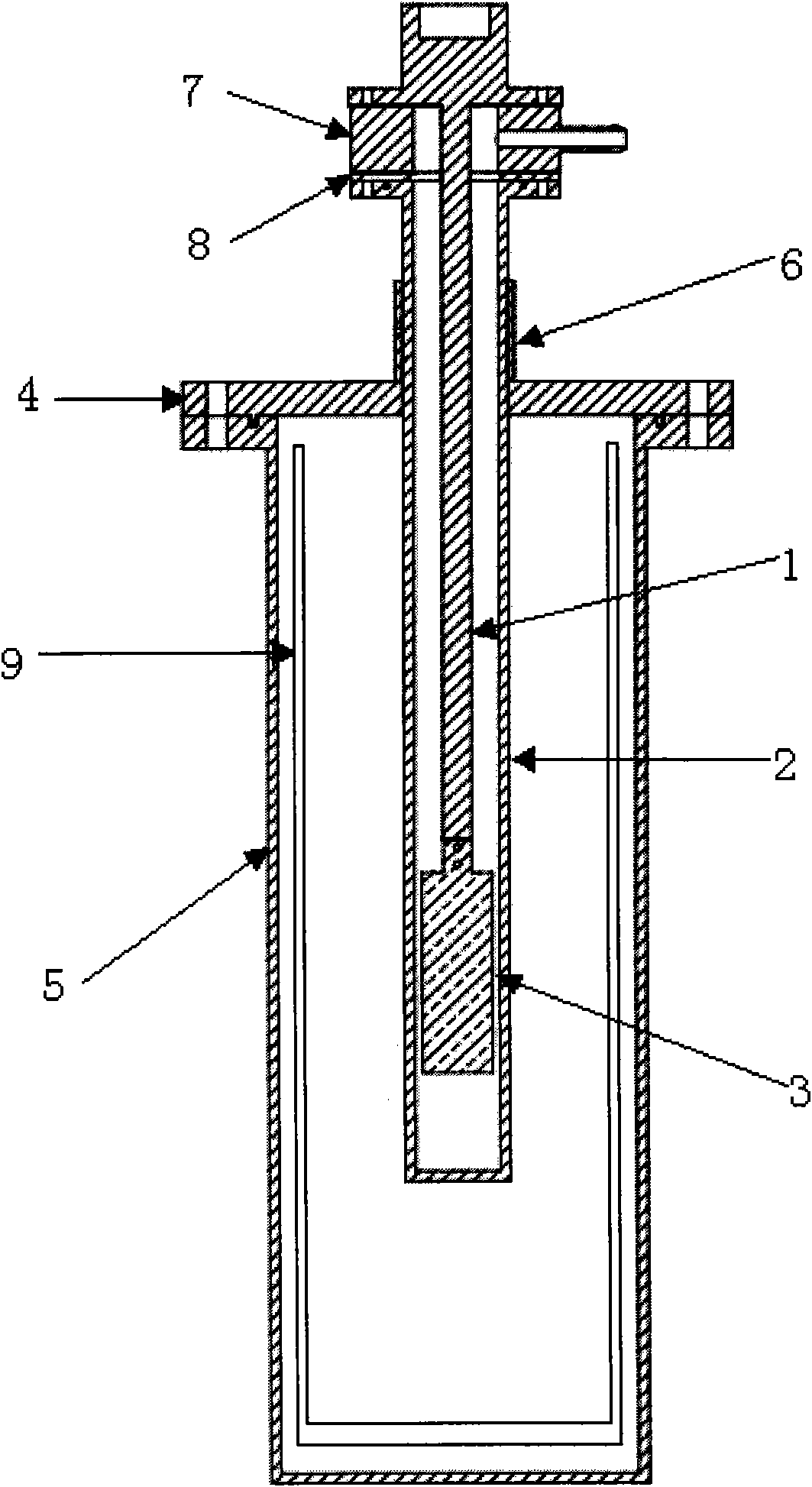

[0021] Such as figure 1 As shown, the refrigeration part includes a Dewar bottle 9 , a Dewar sleeve 5 , a Dewar cover 4 , a low temperature chamber 2 , a vacuum module 7 and an air leakage prevention module 8 . The Dewar bottle 9 is filled with liquid nitrogen of 2 / 3 depth, placed in the Dewar sleeve 5, and the Dewar sleeve 5 and the Dewar cover 4 are fastened with a flange structure to reduce the leakage of liquid nitrogen. There is a hole in the middle of the Dewar cover 4 that is consistent with the outer diameter of the low temperature chamber for insertion of the low temperature chamber 2, and the middle part of the low temperature chamber 2 is covered with a stop sleeve 6 to fix the low temperature chamber 2 and control its insertion depth. The lower end of the sample rod 1 and the sample sheet 3 are fixed with screws, and the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com