Lamp

A discharge capacitor and electrode technology, applied in the field of lamps, can solve the problem of insufficient ultraviolet light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

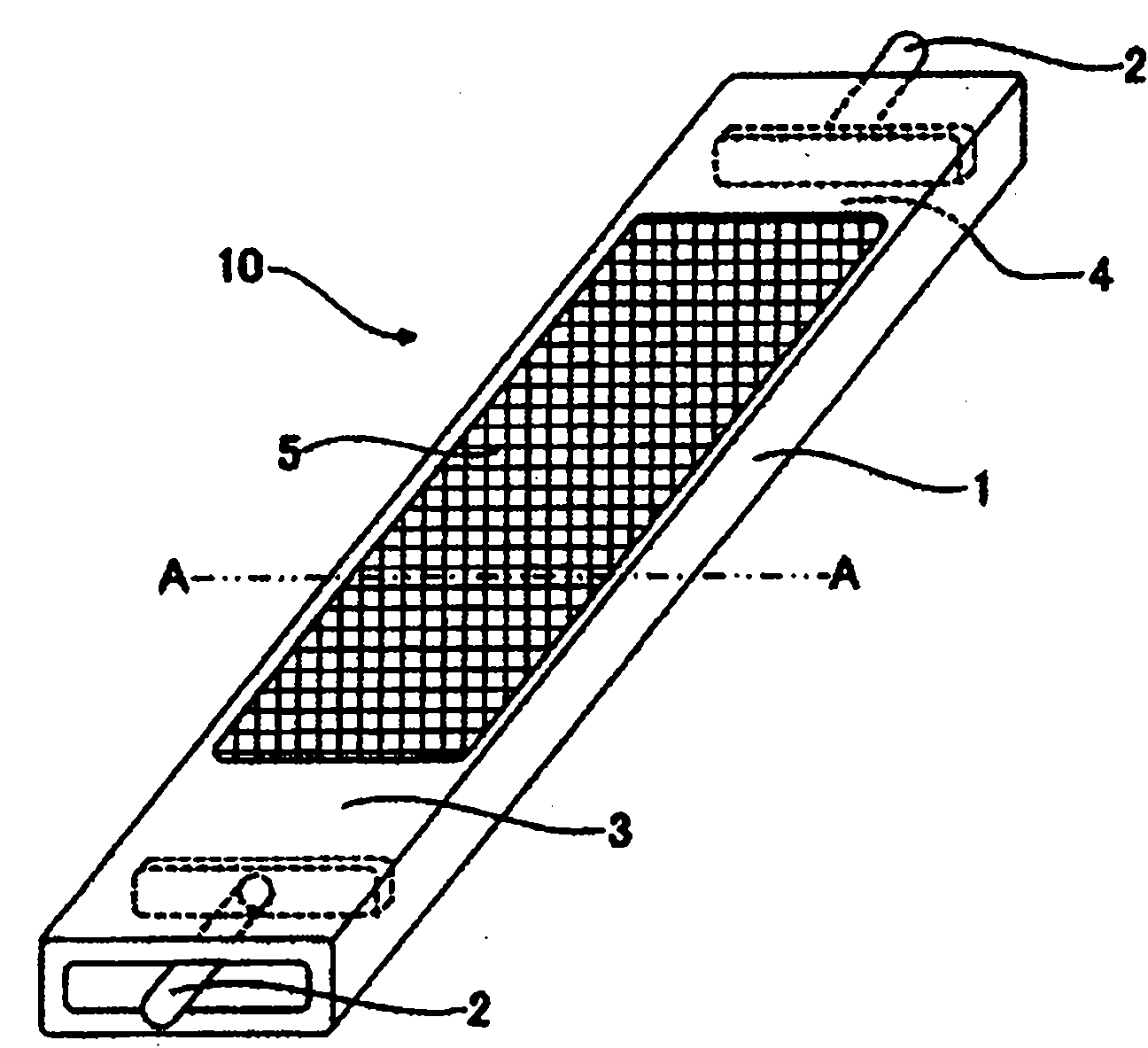

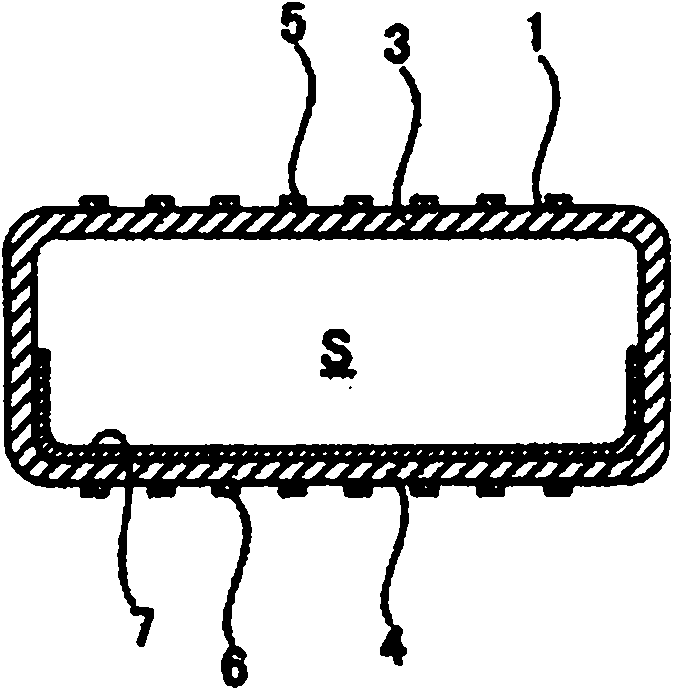

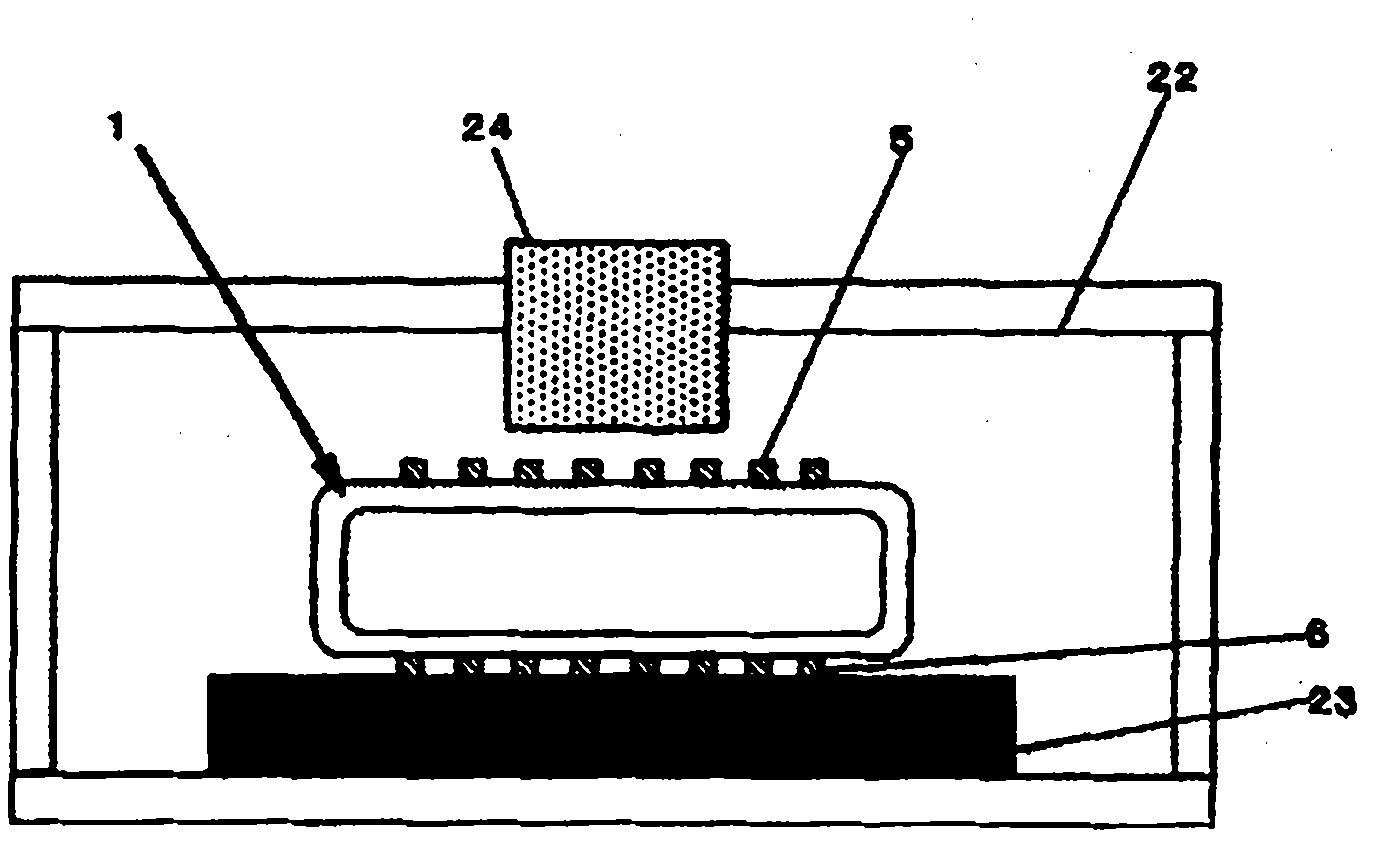

[0036] The lamp of Example 1 is made of quartz glass with a wall thickness of 2 mm, has a total length of 200 mm, a width of 42 mm, a height of 14 mm, and a discharge gap of 10 mm, and has electrodes made of gold with a total length of 130 mm and a width of 32 mm. A discharge gas containing krypton gas and iodine gas is enclosed in the discharge vessel.

Embodiment 2

[0038] The lamp of Example 2 is made of quartz glass with a wall thickness of 2 mm, has a total length of 200 mm, a width of 42 mm, a height of 14 mm, and a discharge gap of 10 mm, and has electrodes made of gold with a total length of 130 mm and a width of 32 mm. A discharge gas containing argon and gaseous iodine is enclosed in the discharge vessel.

Embodiment 3

[0040] The lamp of Example 3 is made of quartz glass with a wall thickness of 2 mm, has a total length of 200 mm, a width of 42 mm, a height of 14 mm, and a discharge gap of 10 mm, and has electrodes made of gold with a total length of 130 mm and a width of 32 mm. A discharge gas containing a mixed gas of iodine gas and a rare gas mixed with krypton gas and argon gas at a mixing ratio of 1:1 was enclosed in the discharge vessel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com