Heat exchanger and refrigerating cycle device provided with same

A technology of heat exchangers and heat transfer tubes, applied in heat exchange equipment, lighting and heating equipment, evaporators/condensers, etc., can solve problems such as reduced device performance, reduced heat exchange volume, and reduced device performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

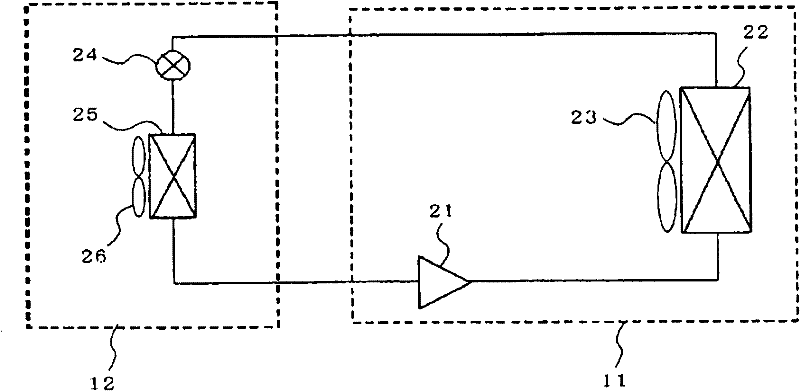

[0035] Embodiment 1 of the heat exchanger of the present invention will be described with reference to the drawings by taking a refrigeration cycle apparatus using the heat exchanger as an example. figure 1 Indicates the refrigerant circuit of a refrigeration unit. This refrigerating device is used for indoor refrigerating by performing a vapor compression type refrigerating cycle operation. exist figure 1 Among them, 11 is an outdoor unit, and 12 is an indoor unit. The outdoor unit 11 includes a compressor 21 , a condenser 22 , and a condenser fan 23 that sends air to the condenser 22 . The indoor unit 12 includes an expansion mechanism 24 , an evaporator 25 , and an evaporator fan 26 that sends air to the evaporator 25 . The compressor 21, the condenser 22, the expansion mechanism 24, and the evaporator 25 constitute a refrigerating cycle, and the inside thereof is filled with a refrigerant for circulation. The present invention is mainly found in the forms of low-temp...

Embodiment approach 2

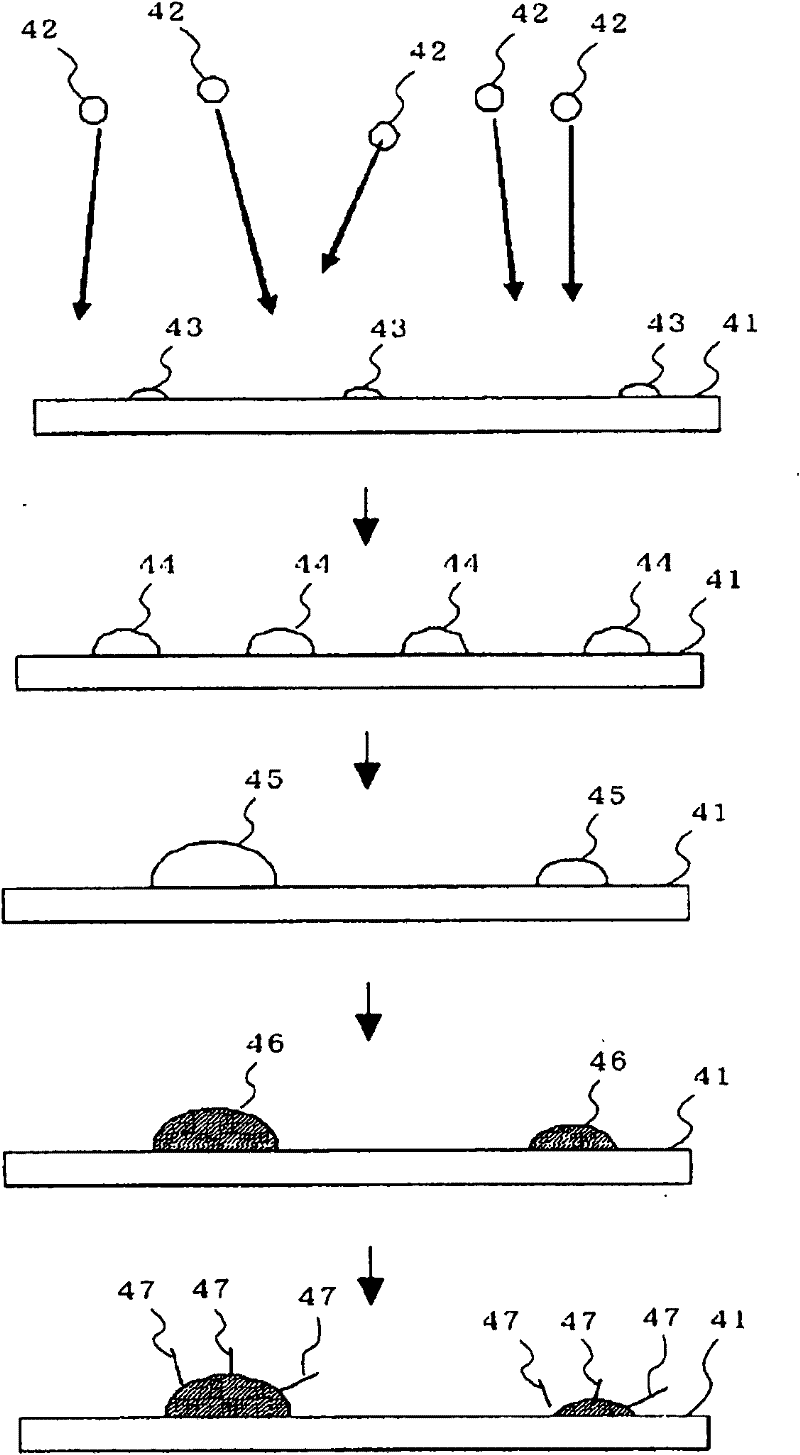

[0059] Next, the heat exchanger according to Embodiment 2 of the present invention will be described. Figure 8 The fins 71 and the heat transfer tubes 72 constituting the evaporator (heat exchanger) 25 are shown. As described above, the condenser (heat exchanger) 25 absorbs heat by vaporizing the liquid refrigerant flowing through the heat transfer tubes 72 , and exchanges heat with the outside air through the fins 71 . As described above, under freezing conditions, the temperature of the surrounding air is -20°C, the evaporation temperature is about -30°C, and the surface of the fin 71 is below 0°C, and frost is formed. Additionally, if Figure 8 As shown, around the heat transfer tube 72, even on the surface of the fin 71, the temperature is particularly low. In Embodiment 2, holes 73 for lowering the freezing point of condensed water droplets are provided by using the Gibbs-Thomson effect of the following formulas (5) and (6) around the entire fins 71 or heat transfer tu...

Embodiment approach 3

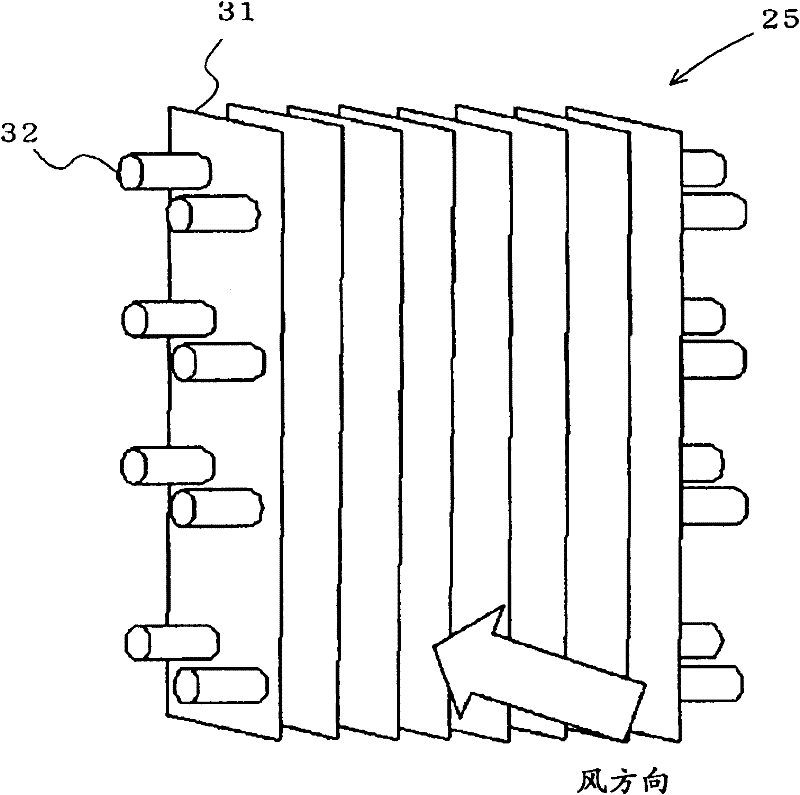

[0072] Next, the configuration of Embodiment 3 of the present invention will be described. Figure 11 An example of a well-known structure of an evaporator (heat exchanger) is shown. In this evaporator (heat exchanger), a plurality of fins 31 are arranged in parallel at regular intervals, and heat transfer tubes 32 pass through the fins 31 . In such a heat exchanger, the fins 31 are cooled to 0° C. or lower, and when frost starts to form, frost grows from both surfaces of the fins 31 facing each other. After a certain period of time, the space between the fins 31 is blocked by frost, the fins 31 are buried, and the performance of the evaporator decreases. For this purpose, the evaporator is defrosted to melt the frost between the fins 31 . The general defrosting method is to switch the four-way valve to reverse the flow of refrigerant, change the evaporator heat exchanger and condenser heat exchanger, and melt the frost.

[0073] Compared with the conventional fins in which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com