Device and method for measuring poses of embedded type spraying gun in real time

A technology of real-time measurement and pose measurement, which is applied in the direction of measuring devices, injection devices, optical devices, etc., can solve the problems of slow processing speed, poor system integration, and large system volume of robot vision systems, and achieve light weight, real-time High performance, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

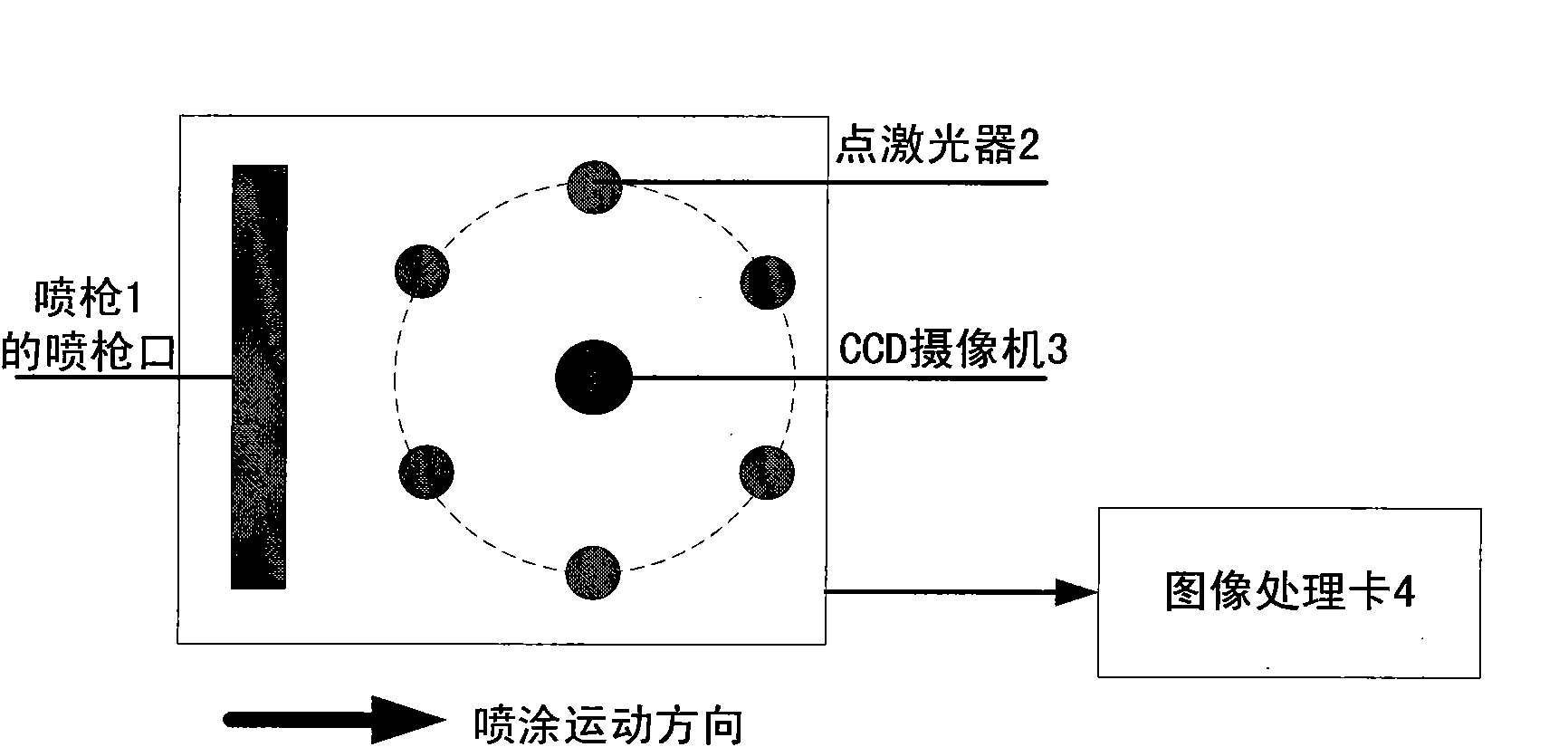

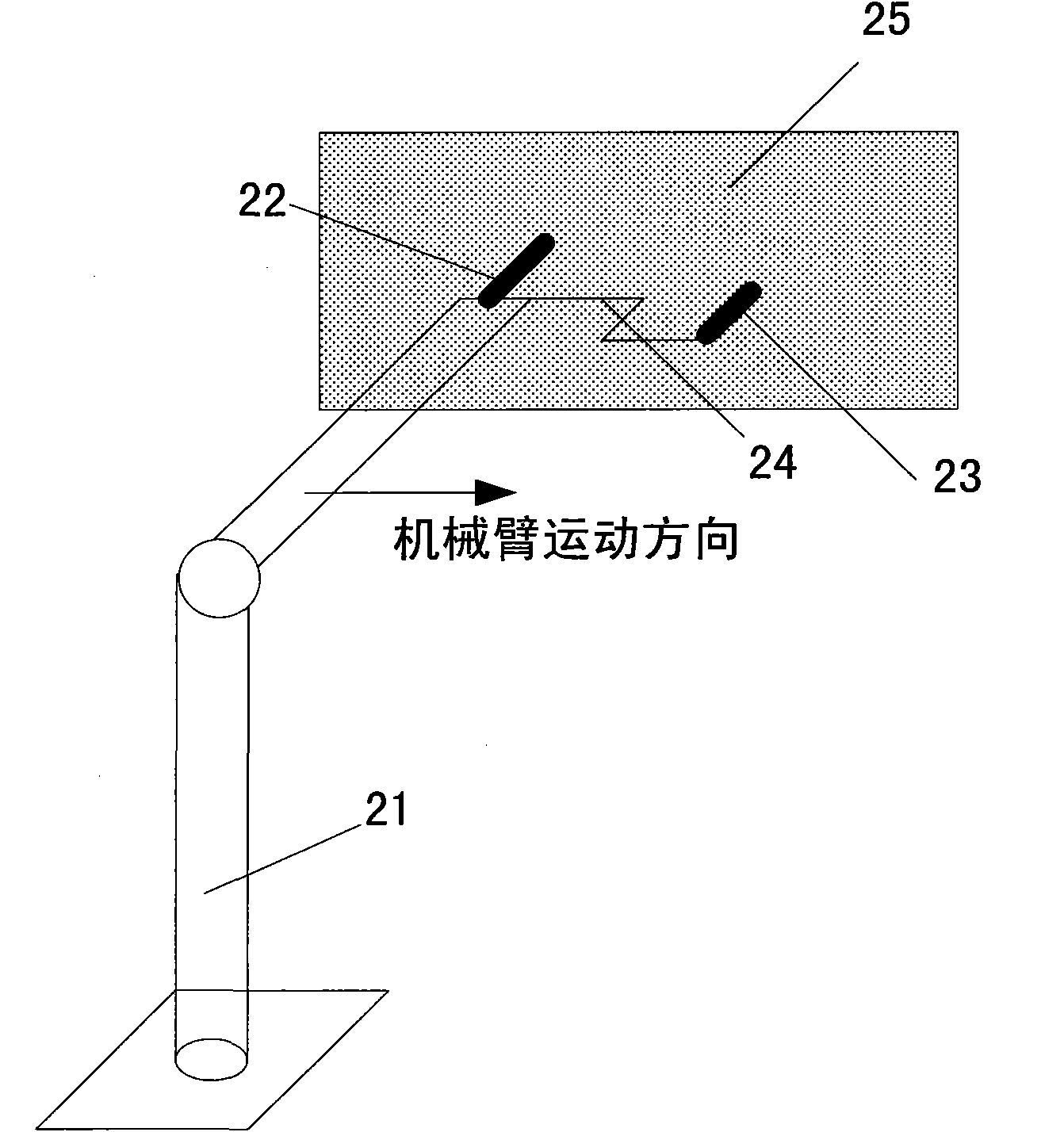

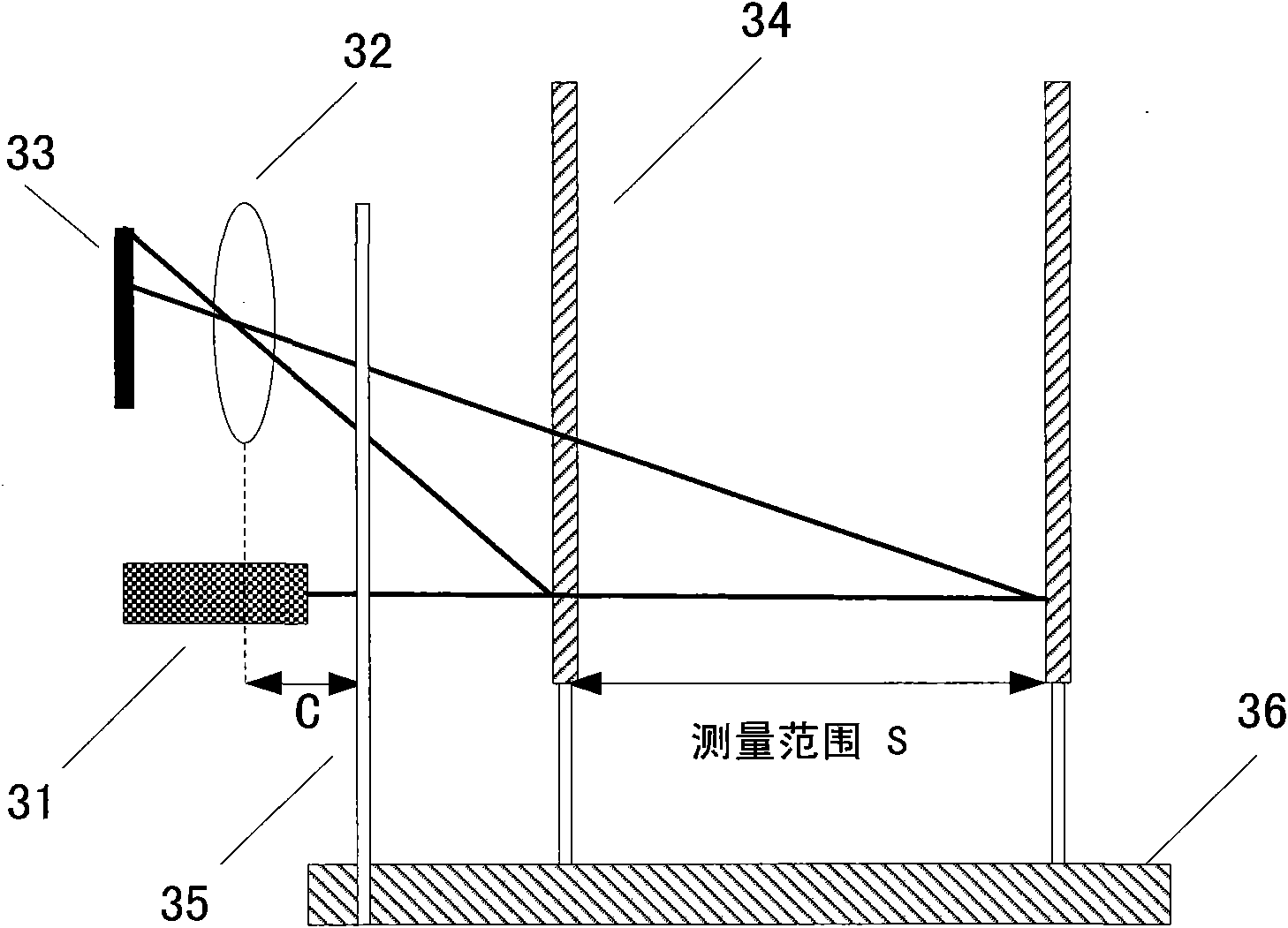

[0032] The basic idea of the present invention is: in order to ensure the spraying quality of the spraying robot, it is necessary to ensure that the spray gun and the surface to be sprayed are kept at a certain distance and perpendicular to each other. Most of the systems currently used for robot pose measurement are based on stereo vision and PC vision systems, but such systems generally have disadvantages such as poor system integration, large volume, heavy weight, and poor real-time performance. Since the end of the spraying robot needs to install loads such as spray guns and spray gun controllers, there are strict requirements on the volume and weight of the measuring devices installed on it, so the visual measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com