High-strength easy-cutting processing gray pig iron

A free-cutting, gray cast iron technology, applied in the field of new high-strength and easy-to-machine gray cast iron materials, to achieve the effect of convenient operation and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Invented alloy structure and properties:

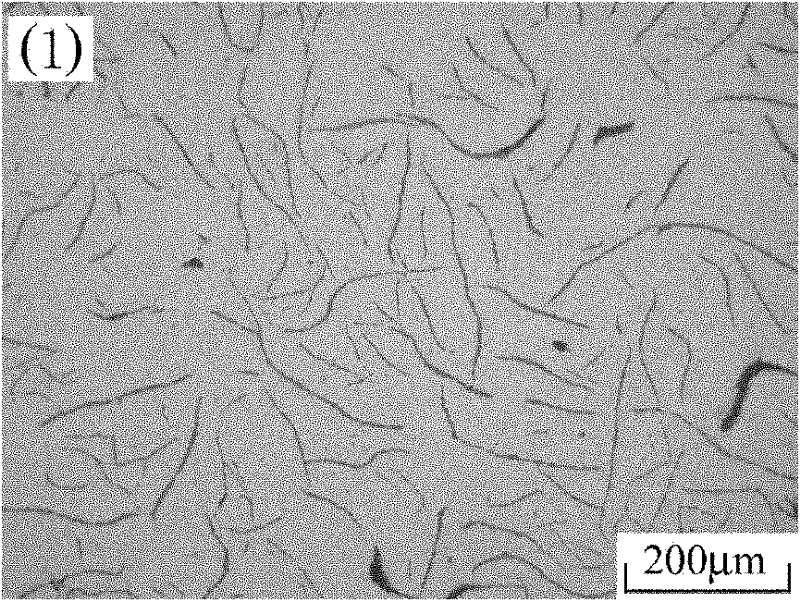

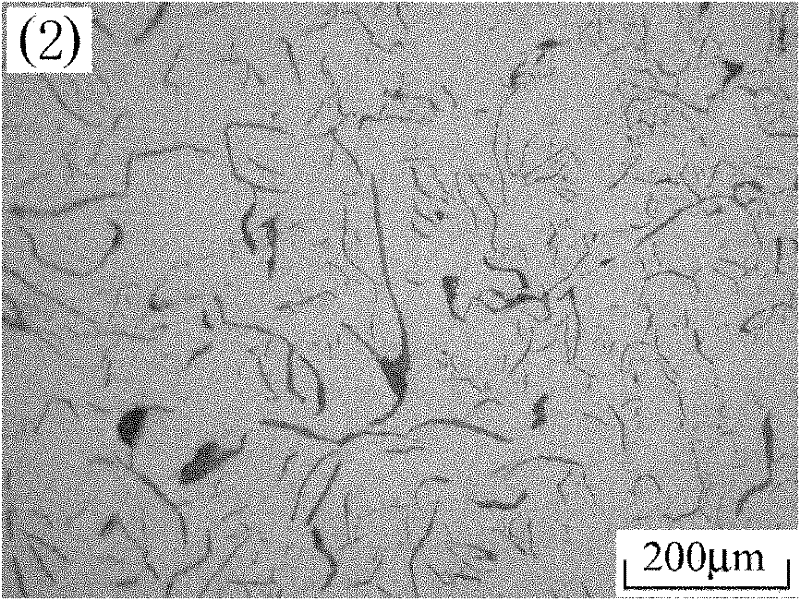

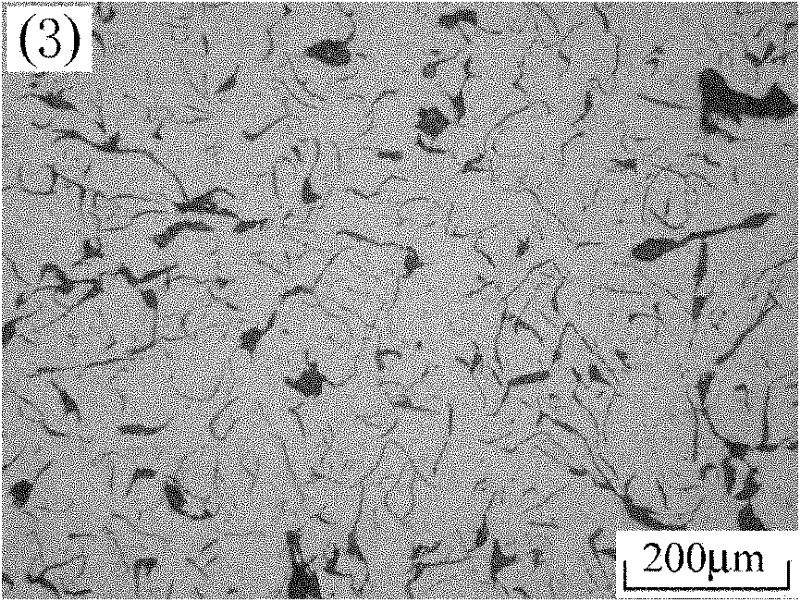

[0021] The high-strength, easy-to-cut gray cast iron of the present invention is smelted in an intermediate-frequency induction furnace. The main raw materials are scrap steel and a recarburizer. The temperature of the molten iron is higher than 1500 degrees Celsius. Compared with the high-strength gray cast iron with Mo added, the high-strength easy-cutting gray cast iron of the present invention eliminates expensive Mo elements, optimizes N, Si, Mn and other elements, increases the content of chemical elements V, and makes the pearlite form cross distribution, The size is reduced, the distance between the sheets is reduced, especially the graphite is fine, curved, the sharp corners become blunt, and the distribution is uniform, such as Figure 1-4 As shown; while improving the strength of gray cast iron, improve its processing performance, because the uniform and dispersed distribution of fine, curved graphite is easy to defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com