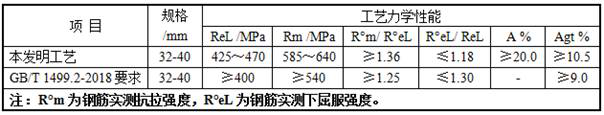

A kind of nitrogen-rich vanadium-niobium microalloyed large-scale hrb400e straight seismic steel bar and preparation method thereof

A technology of vanadium-niobium microalloy and earthquake-resistant steel bar, applied in the metallurgical field, can solve the problems of high steel production cost, unfavorable production cost of steel bar enterprises, lower product market competitiveness, etc. Location and nucleation rate, and the effect of increasing pearlite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

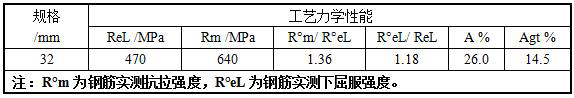

Embodiment 1

[0040] A. Molten steel smelting: 90kg / t respectively 钢 、30kg / t 钢 The cold material is loaded into the proportion, and the scrap steel (chemical composition: C 0.21wt%, Si 0.35wt%, Mn 1.05wt%, P 0.030wt%, S 0.028wt% is added to the LD converter in the following mass ratio, and the rest is Fe and Inevitable impurities) and pig iron (chemical composition: C3.0wt%, Si 0.32wt%, Mn 0.35wt%, P0.095wt%, S 0.018wt%, the rest is Fe and unavoidable impurities); Then press 940kg / t 钢 The proportion of molten iron is loaded into the LD converter with the following temperature and mass ratio of molten iron: molten iron temperature 1350°C, molten iron composition C4.2wt%, Si 0.30wt%, Mn 0.25wt%, P 0.110wt%, S 0.028wt% , the rest is Fe and unavoidable impurities; scrap steel, pig iron and molten iron are blended into the LD converter, then carry out conventional top-bottom compound blowing, adding conventional lime and lightly burned dolomite to make slag, and the amount of lime added is 23k...

Embodiment 2

[0052] A. Molten steel smelting: 92kg / t respectively 钢 、30kg / t 钢 The cold material is loaded into the proportion, and the scrap steel (chemical composition: C 0.23wt%, Si 0.42wt%, Mn 1.32wt%, P 0.040wt%, S 0.036wt% is added in the LD converter, and the rest is Fe and Inevitable impurities) and pig iron (chemical composition: C3.1wt%, Si 0.42wt%, Mn 0.40wt%, P0.106wt%, S 0.031wt%, the rest is Fe and unavoidable impurities); Then press 940kg / t 钢 The proportion of molten iron is loaded into the LD converter with the following temperature and mass ratio of molten iron: molten iron temperature 1360 ° C, molten iron composition C4.4wt%, Si 0.38wt%, Mn 0.32wt%, P 0.122wt%, S 0.038wt% , the rest is Fe and unavoidable impurities; scrap steel, pig iron and molten iron are blended into the LD converter, then carry out conventional top-bottom compound blowing, adding conventional lime and lightly burned dolomite to make slag, and the amount of lime added is 25kg / t 钢 , the addition of l...

Embodiment 3

[0064] A. Molten steel smelting: 95kg / t respectively 钢 、30kg / t 钢 The proportioning ratio of the cold material is loaded, and the scrap steel (chemical composition: C 0.26wt%, Si 0.60wt%, Mn 1.60wt%, P 0.050wt%, S 0.045wt% is added in the LD converter with the following mass ratio, and the rest is Fe and Inevitable impurities) and pig iron (chemical composition: C3.2wt%, Si 0.55wt%, Mn 0.55wt%, P0.120wt%, S 0.045wt%, the rest is Fe and unavoidable impurities); Then press 940kg / t 钢 The proportion of molten iron is loaded into the LD converter with the following temperature and mass ratio of molten iron: molten iron temperature 1370 ° C, molten iron composition C4.5wt%, Si 0.45wt%, Mn 0.40wt%, P 0.135wt%, S 0.045wt% , the rest is Fe and unavoidable impurities; scrap steel, pig iron and molten iron are blended into the LD converter, then conventional top-bottom composite blowing is carried out, conventional lime and lightly burned dolomite are added to make slag, and the amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com