Conversion-drum three-position isolating mode and isolating switch

An isolating switch and three-position technology, applied in the direction of air switch components, etc., can solve the problems of insulation performance impact, limited load capacity, large contact wear, etc., achieve low manufacturing process requirements, easy to achieve electrical performance, and reduce manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

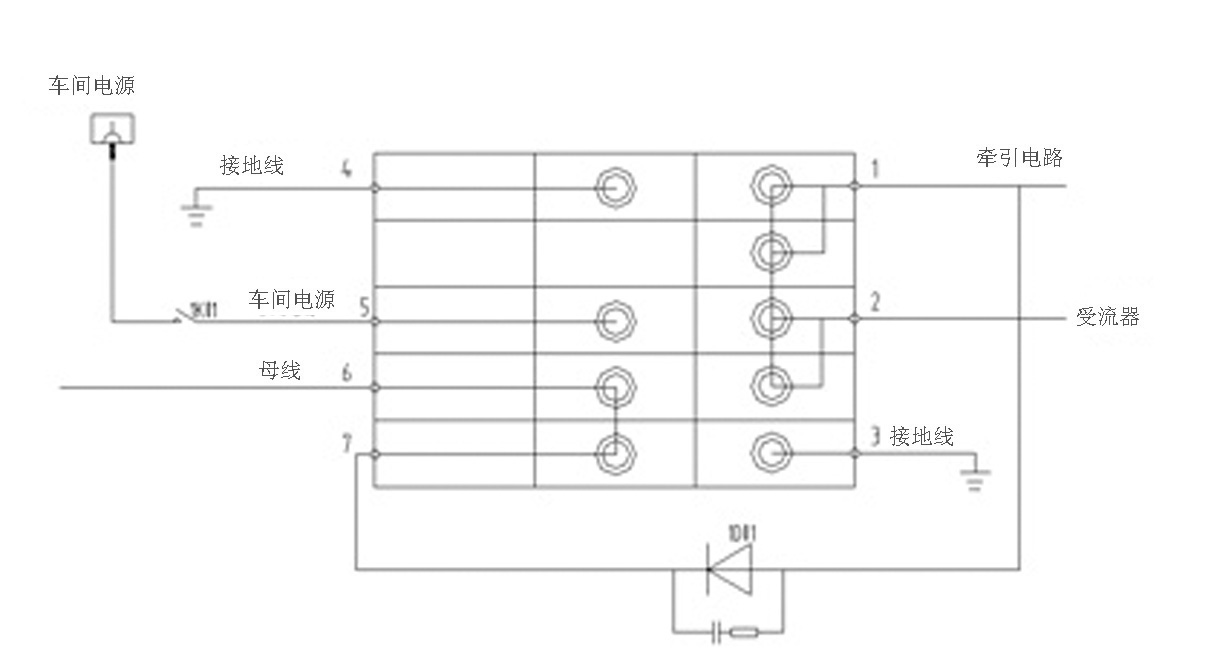

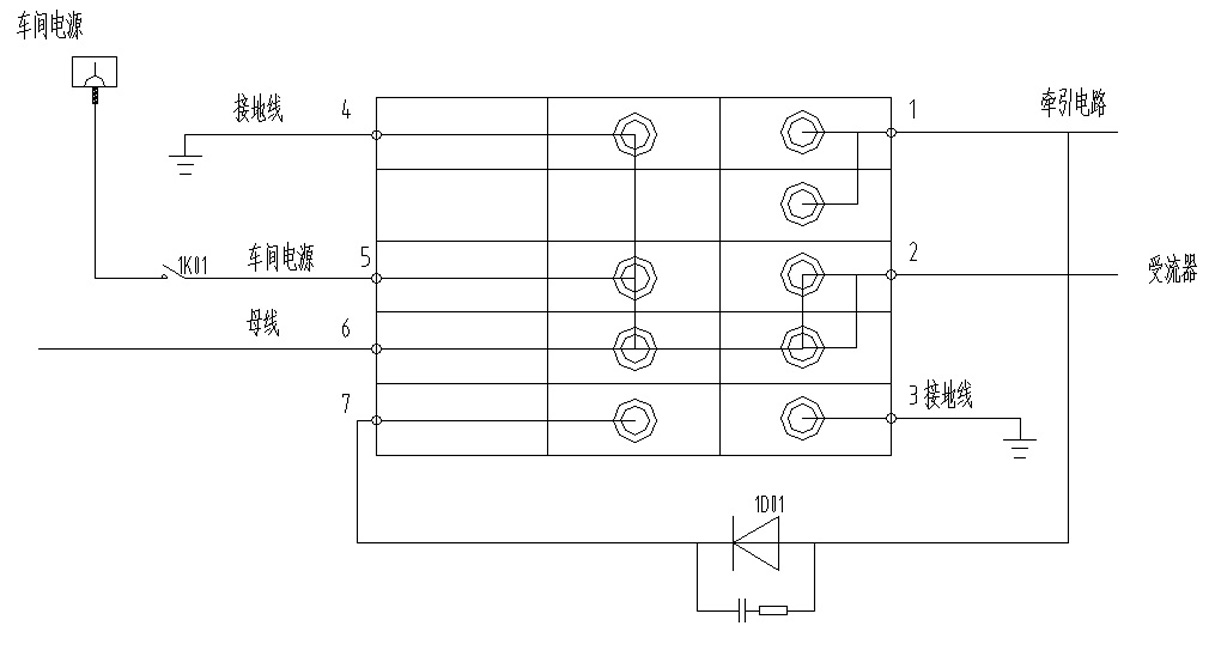

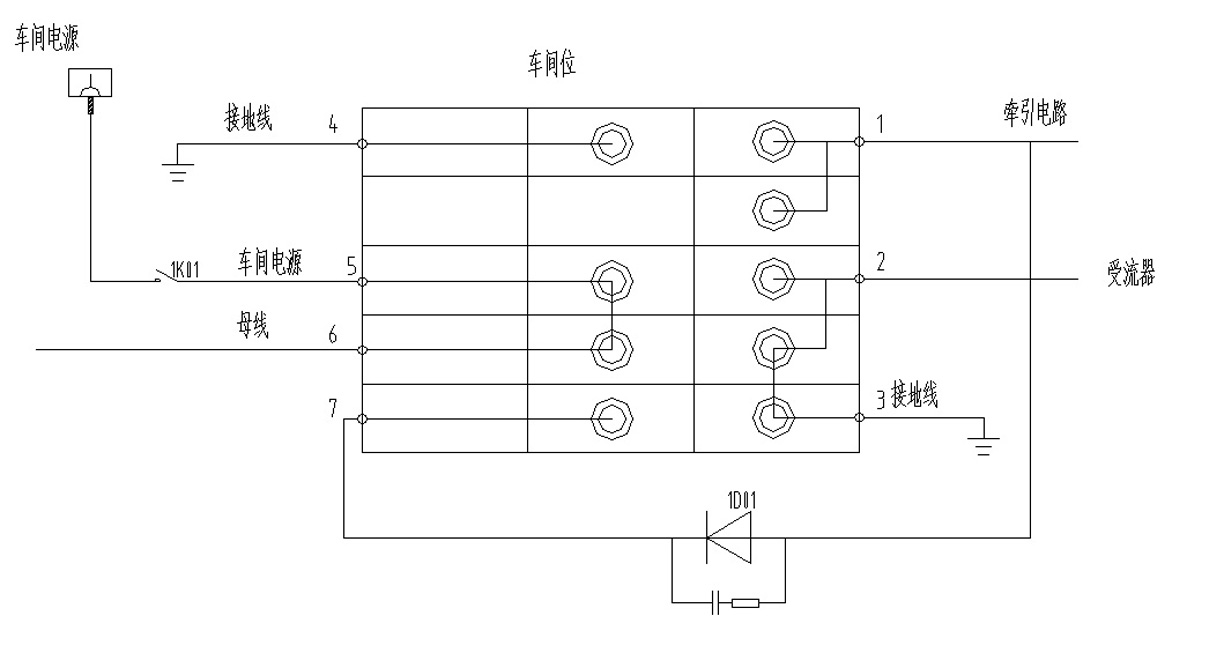

[0024] See attached Figure 1-3 , it can be seen that the present invention relates to a conversion drum type three-position isolation method, through the change of the structure of the copper busbar on the conversion drum and the contact area and insulation distance between the contact fingers to switch on and off the large current and high voltage . The isolation method is to realize the three-position isolation operation through the conversion drum; the operation modes of the three-position isolation operation are the operation mode, the grounding mode and the workshop power supply mode respectively, and the conversion of the contact of the conversion drum is used to allow the load pressure to be adjusted. It becomes a static contact with the large current contact, which is convenient for pressure adjustment. Through the arbitrary rotation of the 360° rotation space of the conversion drum, arbitrary positioning and multi-position contact connection methods can be combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com