High-dropout voltage high-power DC-DC switch power supply for industrial and mining electrical locomotive

A technology for switching power supplies and electric locomotives, applied to output power conversion devices, conversion of DC power input to DC power output, electrical components, etc. The economic burden of the enterprise, high dust concentration and other problems can be solved, and the effect of reliable operation, good frequency response characteristics and simple driving circuit can be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

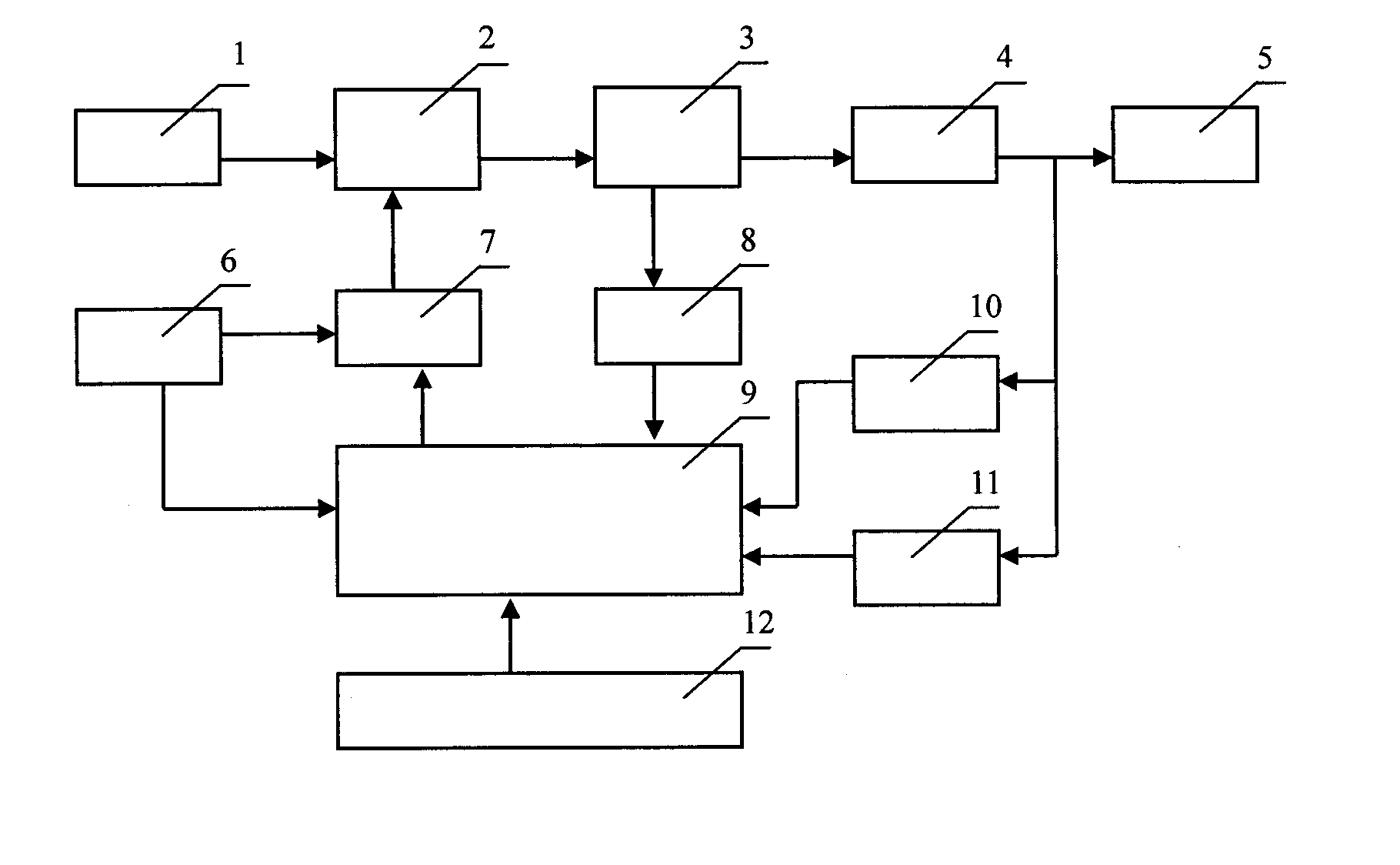

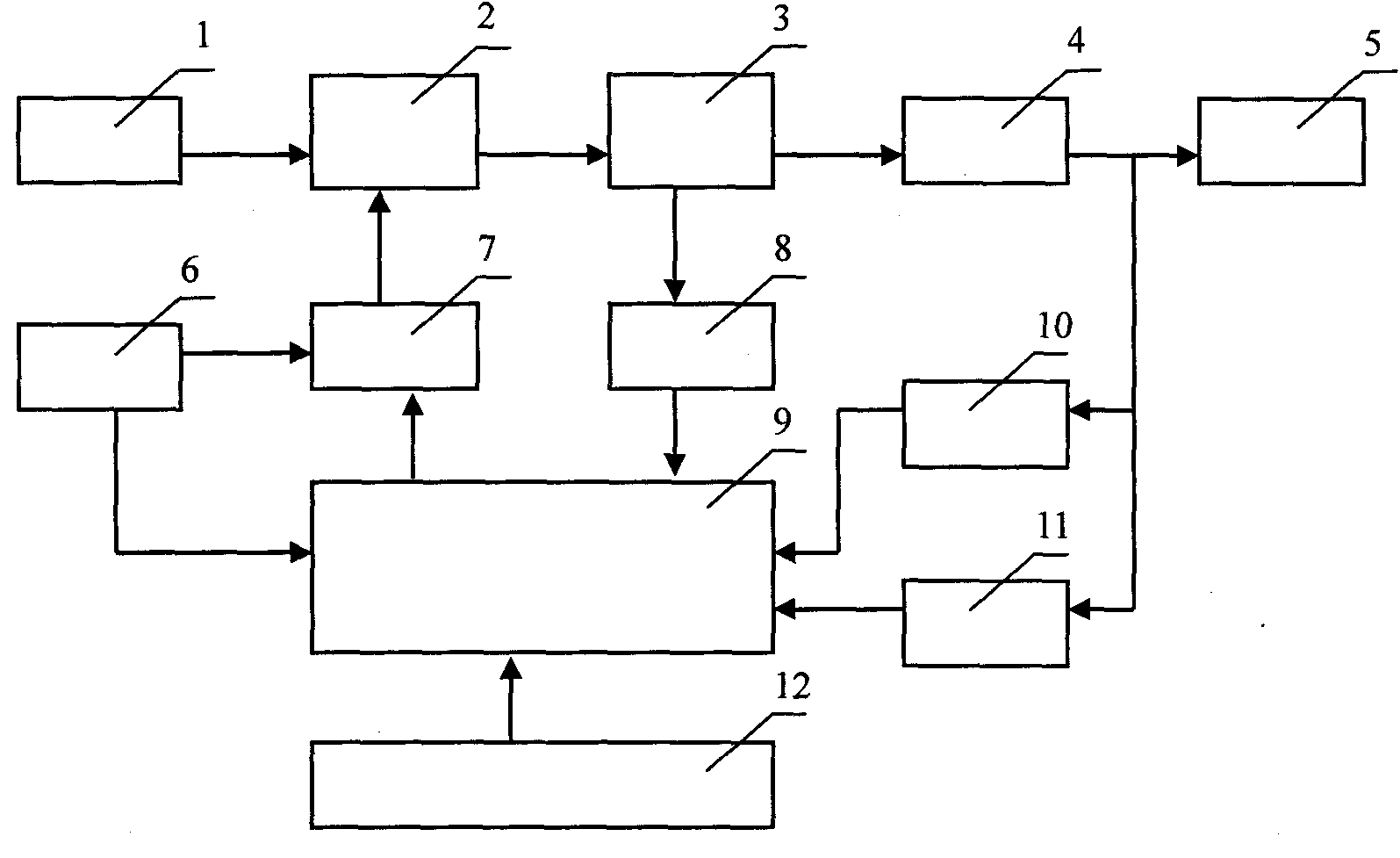

[0015] The high-voltage differential high-power DC-DC switching power supply system for industrial and mining electric locomotives has input filter 1, main circuit 2, switching transformer 3, output rectification 4, output filter 5, auxiliary power supply 6, drive circuit 7, current protection 8, and PWM control circuit 9. Overvoltage protection 10. Voltage feedback 11. Soft start circuit 12. The input signal of the power supply system goes through input filter 1, main circuit 2, switching transformer 3, output rectifier 4 and output filter 5 to supply power to the load; the other way enters the auxiliary power supply 6 to provide working power for the drive circuit 7 and PWM control circuit 9 . The current protection 8 takes the current signal from the switching transformer 3, the overvoltage protection 10 and the voltage feedback 11 take the voltage signal from the output rectification 4, and send it to the PWM control circuit 9; the PWM control circuit 9 generates a pulse w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com