Spherical target ceramic neutron tube and manufacturing method thereof

A technology of neutron tubes and ceramics, which is applied in the field of electronic device structure, can solve the problems of easy short circuit and insufficient convergence of ion beams, and achieve the problems of insufficient axial magnetic field, improvement of proton ratio of extracted beam, and increase of target area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

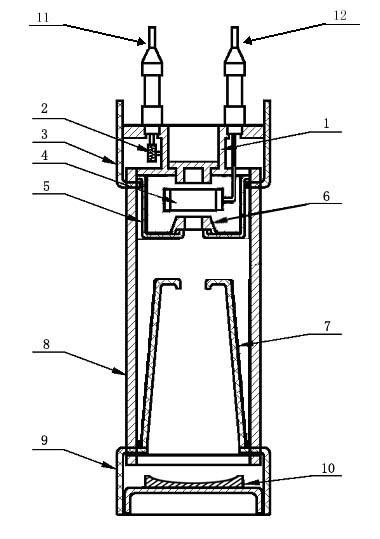

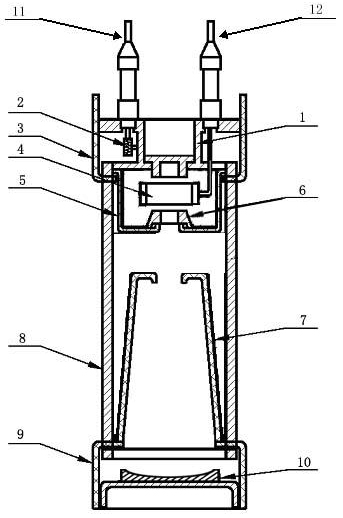

[0014] according to figure 1 As shown, the body of the neutron tube of the present invention consists of an upper envelope 3, a ceramic shell 8, and a lower envelope 9 to form a closed circular axisymmetric structure, and the target 10 is fixed on the inside of the lower envelope 9 and is packaged at the bottom of the ceramic shell 8; The frame 1 is provided with a high-voltage electrode 12 and a storage electrode 11 fixed on the upper port of the ceramic shell 8 through the upper cover 3, and the ceramic shell 8 is provided with an acceleration cylinder 7; the anode cylinder 4 is arranged on the ion source cover 5 and the electrode frame 1 Between, and connected with the high-voltage electrode 12; The reservoir 2 is set in the frame of the electrode holder 1 and connected with the electrode 11 of the reservoir; The ion source cover 5 is arranged in the upper port of the ceramic shell 8, and the magnetic material ring 6 is outsourced and can be installed with a valve plate In ...

Embodiment 2

[0016] In the structure of Embodiment 1, the shape of the end of the target 10 of the neutron tube can be made into a spherical shape, and the center of the spherical surface is coaxial with the central hole of the accelerating tube 7 .

[0017] Taking the Φ50 neutron tube as an example, after improvement, the service life is increased by more than 2 times, the output is increased by about 3 times, the stability is not more than 3%, and the yield is higher than 90%.

Embodiment 3

[0019] The electrode frame 1 and the target 10 are manufactured, the electrode frame 1 is provided with a high-voltage electrode 12 and a storage electrode 11 fixed on the upper port of the ceramic shell 8 through the upper cover 3, and the shape of the end of the target 10 is made into a spherical shape R=25mm, The center of the sphere is taken as the center hole center of the acceleration tube 7; then the upper cover 3, the ion source cover 5, the magnetic material ring (NdFeB permanent magnet material) 6 are outpacked with kovar, the acceleration tube 7, and the lower cover 9 Sealed together with the ceramic shell 8 to ensure that the aperture of the magnetic material ring 6 is the same as the aperture of the ion source cover 5 lead-out hole; then the storage 2, the anode cylinder 4 and the electrode frame 1 are welded together and put into the upper cover 3; the upper edge of the electrode frame 1 and the edge of the upper cover 3, the lower edge of the spherical target 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com