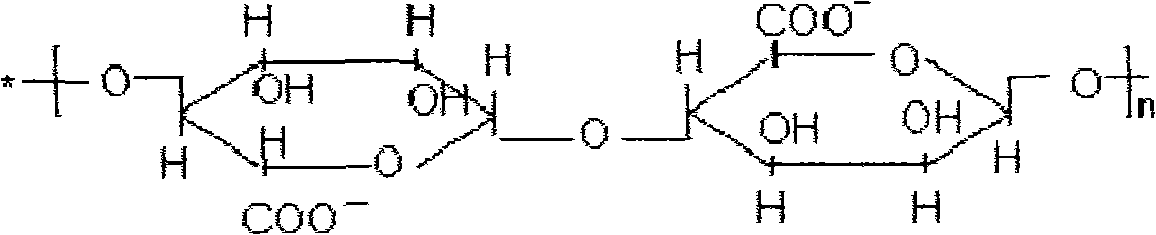

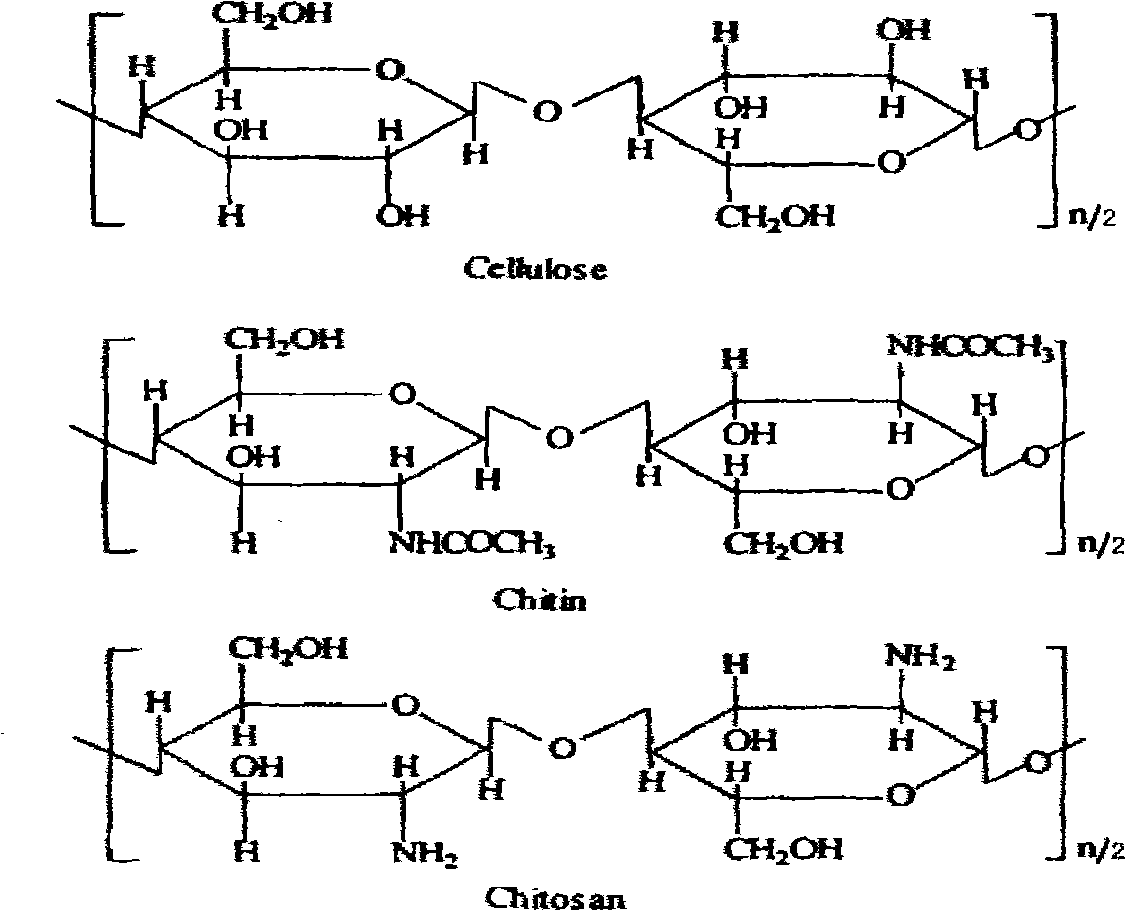

Method for preparing alginate/cellulose composite fibers

A composite fiber and alginate technology, which is applied in the direction of cellulose/protein conjugated artificial filament, fiber chemical characteristics, textiles and papermaking, etc., can solve the problem of poor spinnability, failure to achieve mixing effect, and fiber content Mechanical indicators, functional indicators and other issues to achieve the effect of improving compatibility and ensuring content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) The cellulose cotton pulp is soaked and alkalized by 235g / l NaOH solution, the alkalization time is 0.45 hours, the hemicellulose content in the soaked alkali solution is not more than 3wt%, and crushed by pressing, aged at 25°C for 5 Obtained the alkali cellulose containing α-cellulose 27wt%, NaOH 14.5wt% in one hour.

[0031] (2) Sodium alginate was added into the alkali cellulose according to 3wt% of the alkali cellulose, and mixed and stirred for 50 minutes, and mixed evenly.

[0032] (3) In the above-mentioned mixture of alkali cellulose and sodium alginate, add relative α-cellulose and sodium alginate 34.5wt% CS 2 , carry out yellowing reaction 1.3 hours, generate cellulose xanthate and alginate xanthate, add deionized water to dissolve then, prepare to contain cellulose xanthate and alginate xanthate 6.8wt%, NaOH 5.8wt% cellulose / alginate xanthate viscose.

[0033] (4) The above cellulose / alginate xanthate viscose is filtered, defoamed, and matured to obtai...

Embodiment 2

[0037] (1) The cellulose bamboo pulp is soaked and alkalized by 245g / l NaOH solution, the alkalization time is 1.45 hours, the hemicellulose content in the soaked alkali solution is no more than 4wt%, and crushed by pressing, aged at 35°C for 4 hours to obtain alkali cellulose containing α-cellulose 29wt% and NaOH 17.5wt%.

[0038] (2) Add sodium alginate into the alkali cellulose according to 4wt% of the alkali cellulose, and mix and stir for 40 minutes, and mix well.

[0039] (3) In the above-mentioned mixture of alkali cellulose and sodium alginate, add relative α-cellulose and sodium alginate 37.5wt% CS 2 , carry out yellowing reaction 2 hours, generate cellulose xanthate and alginate xanthate, add deionized water to dissolve then, prepare to contain cellulose xanthate and alginate xanthate 7.2wt%, NaOH 5.9wt% cellulose / alginate xanthate viscose.

[0040] (4) The above-mentioned cellulose / alginate xanthate viscose is filtered, defoamed, and matured to obtain a falling ball...

Embodiment 3

[0044] (1) Alkaline the cellulose cotton pulp by soaking in 250g / l NaOH solution for 2 hours, the content of hemicellulose in the soaking lye should not exceed 3.5wt%, crush it by pressing, and age at 30°C After 5 hours, alkali cellulose containing α-cellulose 30wt% and NaOH 18wt% was obtained.

[0045] (2) Add sodium alginate into the alkali cellulose according to 3.5wt% of the alkali cellulose, and mix and stir for 55 minutes, and mix well.

[0046] (3) In the above-mentioned mixture of alkali cellulose and sodium alginate, add relative α-cellulose and sodium alginate 40wt% CS 2 , carry out the yellowing reaction for 2.5 hours to generate cellulose xanthate and alginate xanthate, then add deionized water to dissolve, and then add 1.5wt% CS relative to α-cellulose and sodium alginate 2 , carry out secondary yellowing reaction, and prepare cellulose / alginate xanthate viscose containing cellulose xanthate and alginate xanthate 7.5wt%, NaOH6.0wt%.

[0047] (4) The above cellul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Falling ball viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com