Charge pump circuit

A technology of charge pump and circuit, applied in the field of charge pump, which can solve problems such as burnout, increase of transistor switch SW3, time delay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

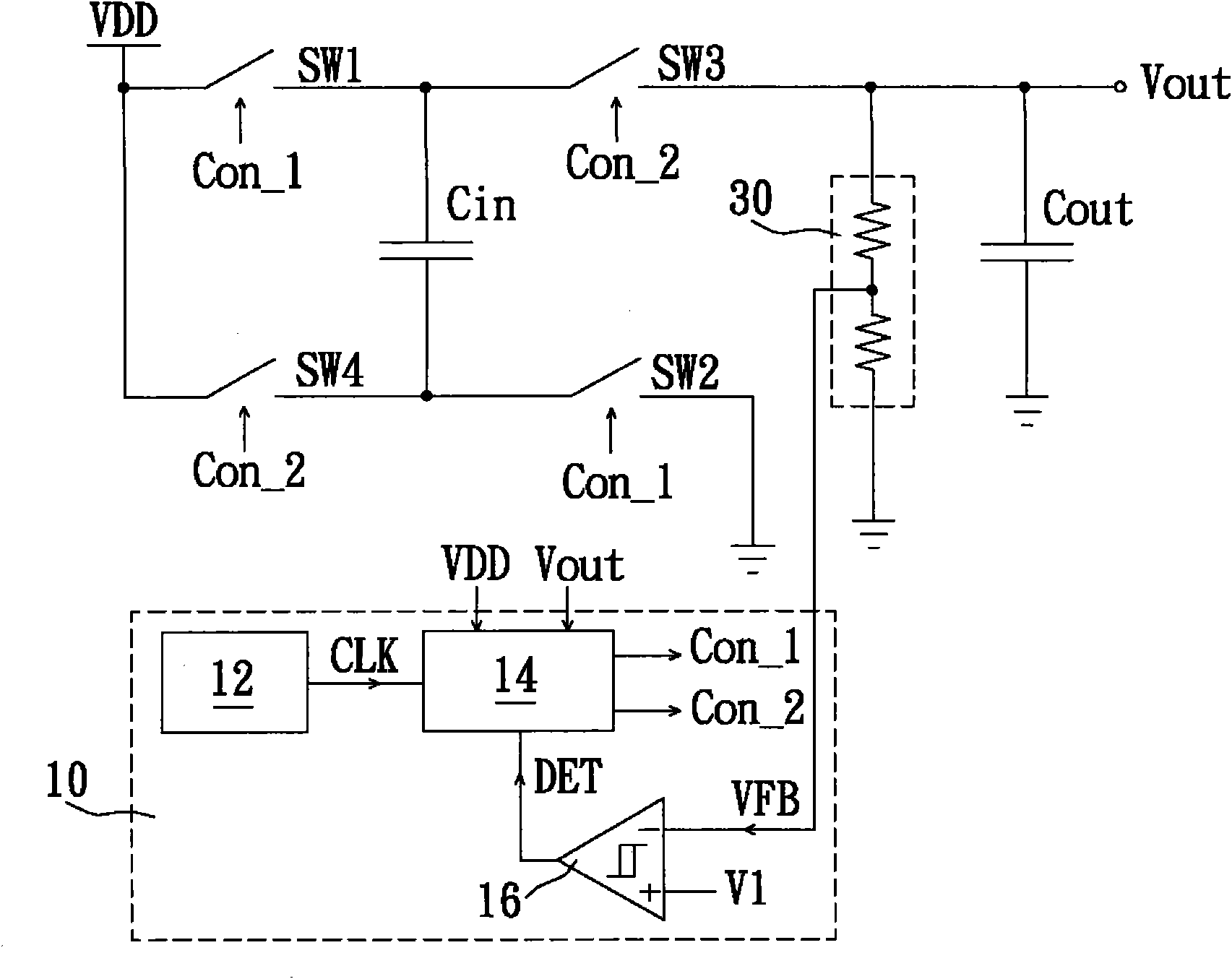

[0046] Please refer to image 3 , image 3 It is a schematic diagram of a charge pump circuit according to a first preferred embodiment of the present invention. The charge pump circuit includes a control unit 100 , a first capacitor unit Ci, a second capacitor unit Co, a charging path and a discharging path. The charging path includes a first P-type metal-oxide-semiconductor transistor PM1, a second N-type metal-oxide-semiconductor transistor NM2, and an input rectifying element D1. The first P-type MOS transistor PM1 is connected to an input voltage VDD and a first terminal of the first capacitor unit Ci, and the negative terminal of the parasitic diode is connected to the input voltage VDD, and the positive terminal is connected to the output voltage Vout. The second NMOS transistor NM2 is connected to a second terminal of the first capacitor Ci and the ground, and the negative terminal of the parasitic diode is connected to the input voltage VDD, and the positive termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com