Refrigerator

A cold storage and storage room technology, applied in the field of cold storage, can solve the problems of difficulty in quickly detecting food temperature, complicated control, waste of cooling energy, etc., and achieve the goal of shortening continuous operation time, shortening passing time, and suppressing the amount of dripping water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

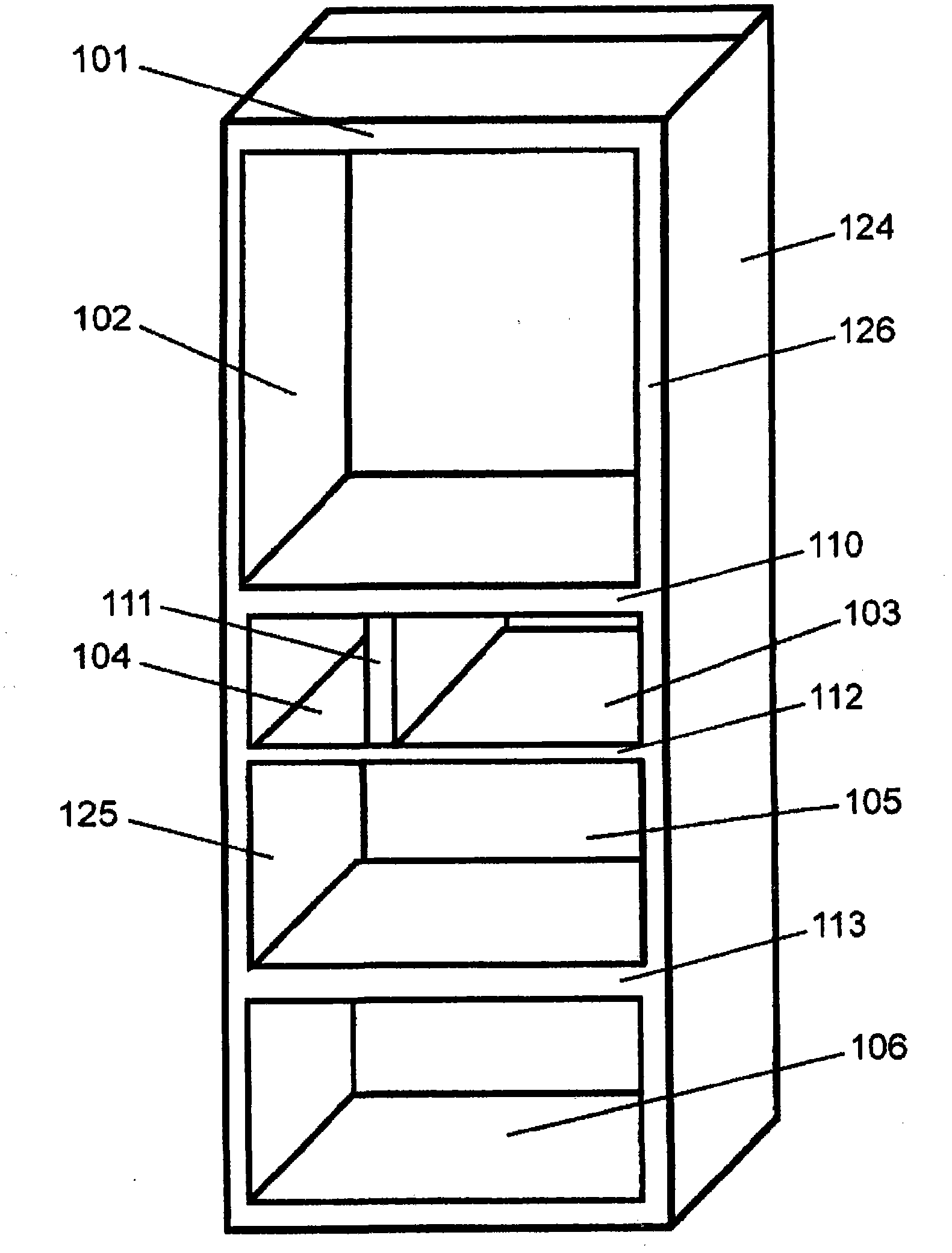

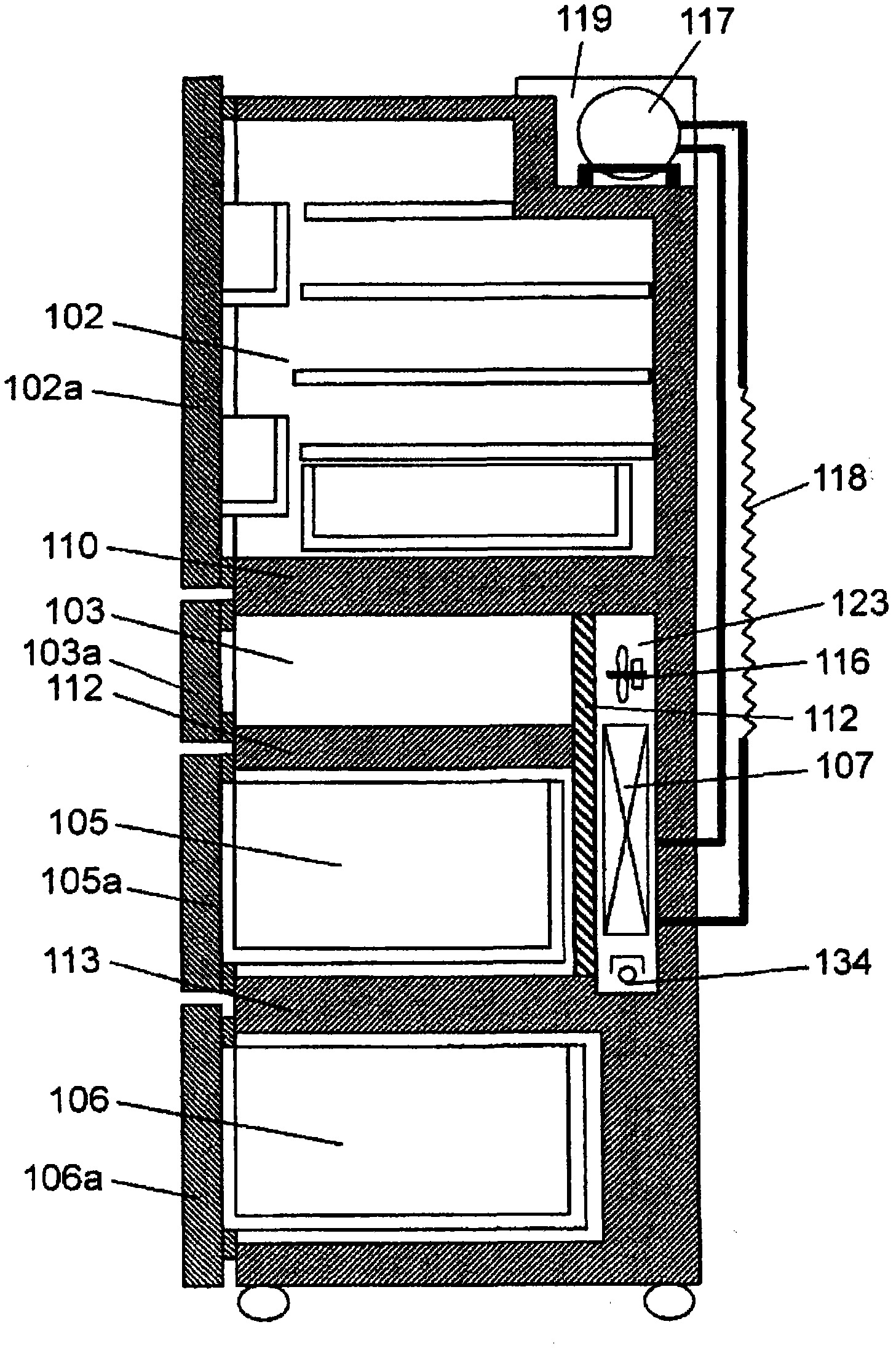

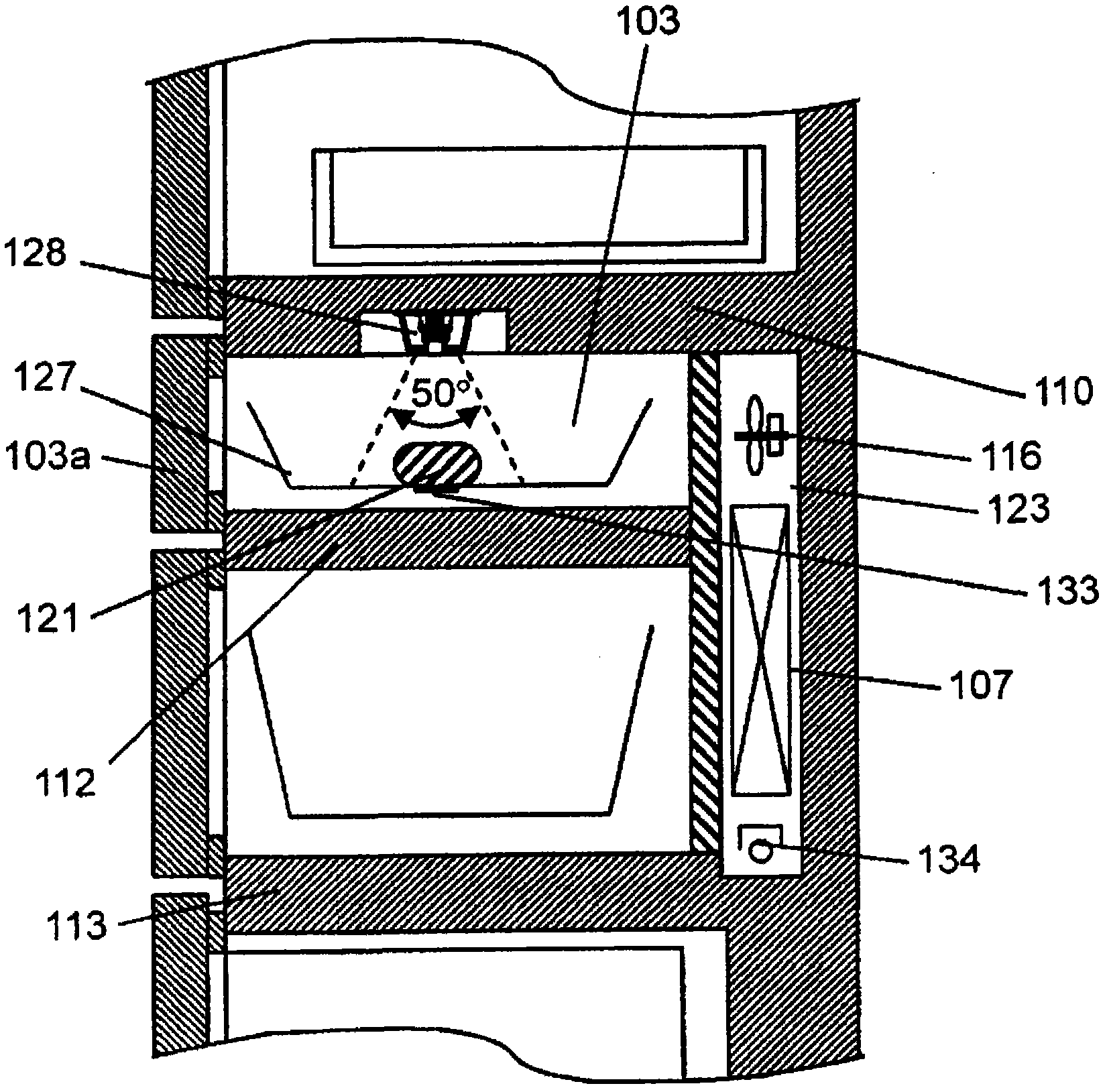

[0091] figure 1 It is a front view of the refrigerator in Embodiment 1 of this invention. figure 2 It is a side sectional view of the refrigerator in Embodiment 1 of this invention. image 3 It is a partially enlarged side sectional view of the upper freezer compartment according to Embodiment 1 of the present invention.

[0092] Such as Figure 1 ~ Figure 3 As shown, the refrigerator main body 101 is made of a metal (for example, iron plate) outer box 124 and a hard resin (for example, ABS) inner box 125 opened to the front, and the outer box 124 and the inner box are filled with foam. The heat insulation box body that polyurethane heat insulation material 126 constitutes between box 125, and is arranged on the refrigerating room 102 of the top of this main body, is arranged on the upper freezer room 103 of the bottom of refrigerating room, in the below of refrigerating room 102 and the upper part. The freezer compartment 103 is composed of an ice-making compartment 104 ...

Embodiment approach 2

[0132] In this embodiment, a detailed description of the same configuration and technical idea as those described in Embodiment 1 will be omitted. Regarding the configuration to which the same technical idea as that described in Embodiment 1 can be applied, a configuration in combination with the technical content and configuration described in Embodiment 1 can be realized.

[0133] Figure 4 It is a partially enlarged side sectional view of the refrigerator according to Embodiment 2 of the present invention. Such as Figure 4 As shown, in the present embodiment, in the configuration of the first embodiment, the surface detected by the infrared sensor 228 installed in the upper freezer compartment 203 is only the container 227, and the third heat-insulating partition located below it is removed. In this Embodiment, the mark 133 is provided also in the place where the infrared sensor 228 of the food mounting surface can detect the temperature with the highest precision.

[0...

Embodiment approach 3

[0137] In the present embodiment, descriptions of parts that have the same configuration or the same technical idea as those described in Embodiment 1 or 2 are omitted. Regarding the configuration to which the same technical idea as that described in Embodiment 1 or 2 can be applied, a configuration that combines the technical content and configuration described in Embodiment 1 or 2 can be realized.

[0138] Figure 5 A partially enlarged side sectional view of a refrigerator according to Embodiment 3 of the present invention. exist Figure 5 Among them, the infrared sensor 328 is installed on the door part of the upper freezer compartment 303, and when the door is opened and closed, the detected temperature and the like are sent to the control part of the refrigerator main body 301 by wireless.

[0139] Thus, even when the door is opened when the food 321 is taken out, the temperature of the food 321 in the casing 327 can be reliably detected, so it is effective for checkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com