Sticker for dustproof film assembly

A technology of dust-proof film components and dust-proof films, which is applied in the direction of film/sheet-shaped adhesives, adhesives, and originals for photomechanical processing, to achieve the effect of suppressing false detection and preventing the decline in yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

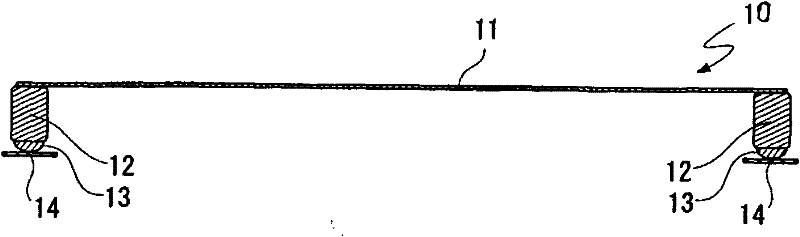

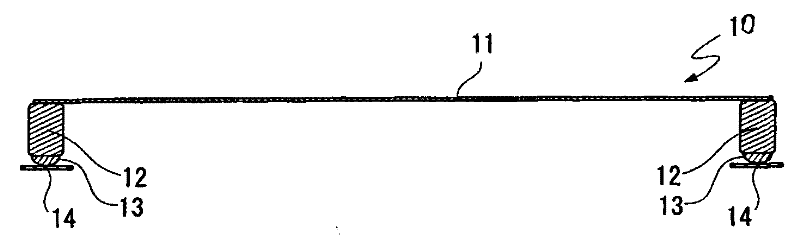

Image

Examples

Embodiment 1

[0032] First, fabricate the pellicle frame. The outer dimensions are 782×474mm, the inner dimensions are 768×456mm, and the height is 5.0mm. , the width of the flat surface of the two ends of the frame is 4.0mm, the inner radius of the corner is 2.0mm, and the outer radius is an aluminum alloy dustproof film assembly frame of 6.0mm, and its surface is treated with black aluminum oxide film .

[0033] The pellicle frame was carried into a clean room, thoroughly washed with a neutral detergent and pure water, and dried.

[0034] As an adhesive with a total light transmittance of 70% or less, fumed silica (fumed silica) Musil was added to 100 parts by mass of silicon adhesive X-40-3122 (manufactured by Shin-Etsu Chemical Co., Ltd., trade name). -120A (manufactured by Shin-Etsu Chemical Co., Ltd., trade name) was mixed and prepared. Thereafter, the prepared adhesive was applied to the lower end surface of the pellicle frame.

[0035] Then, the adhesive was air-dried until it st...

Embodiment 2

[0038] In addition to 100 parts by mass of silicon adhesive X-40-3122 (manufactured by Shin-Etsu Chemical Co., Ltd., trade name), 0.3 parts by mass of black carbon paste (カ一ボンペースト) K-LIMS color-02 (Shin-Etsu Chemical Kogyo Co., Ltd., trade name), except for mixing and preparing, the production of the pellicle was carried out in the same manner as in Example 1.

Embodiment 3

[0040] In addition to adding 3 parts by mass of black iron oxide paste (ペ一スト) K-color-FE035 (Shin-Etsu Chemical Co., Ltd. Co., Ltd., trade name), except for mixing and preparing, the production of the pellicle was carried out in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com