Measuring method and device for characterizing a semiconductor component

A technology of measuring device and measuring method, which is applied in the direction of single semiconductor device testing, measuring device, measuring electricity, etc., to achieve the effect of low equipment cost and simplified analysis and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

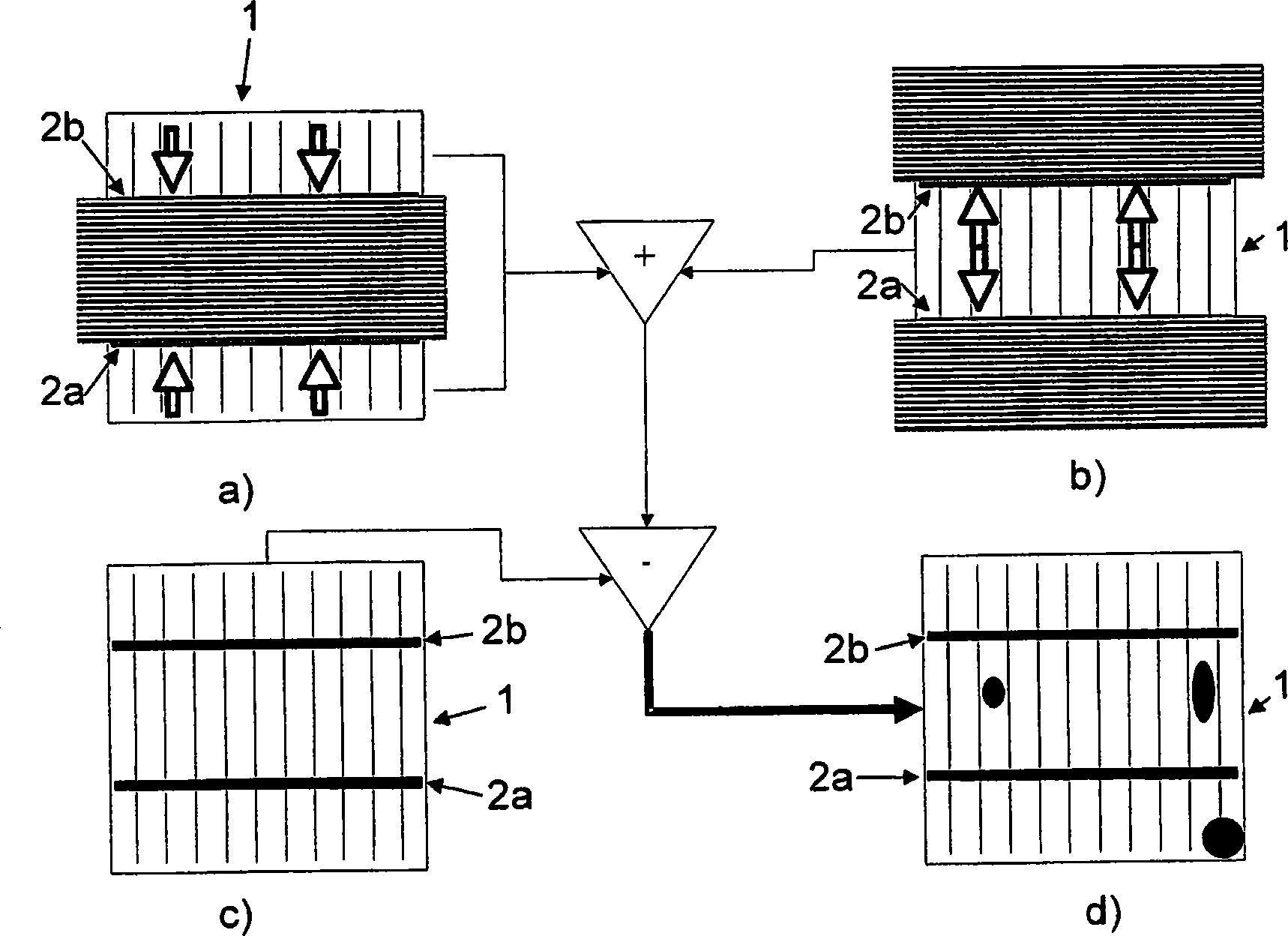

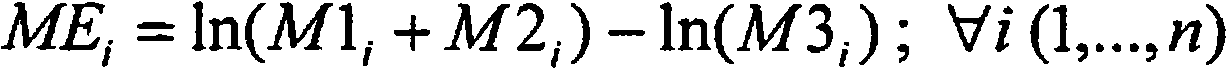

[0094] figure 1 The application of an embodiment of the measuring method for measuring a semiconductor component 1 according to the present invention is shown. The semiconductor component is designed as a solar cell with two metallization lines 2a and 2b extending parallel to each other. Lines are bus bars of metallized structure.

[0095] For the measurement, a conventional photoluminescence measuring device is used, which is extended with a correction unit with two optical filters.

[0096] During the measurement, the battery is not electrically connected. A total of three measurements are performed, and in each measurement, each camera of the measurement device performs photography with a measurement time of one second each. The difference between these three measurements is only in the shielding conditions for the excitation beam. The measuring surface is figure 1 The front side of the solar cell shown in a, b, c, d.

[0097] In the first measurement ( figure 1 a) In the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com