Microscopic bubble combined trapezoid spray tray and connection method of valve body and tray

A technology of micro-bubbles and mass transfer towers, applied in chemical instruments and methods, chemical/physical/physicochemical processes, fractionation, etc., can solve problems such as large liquid level drop, poor contact effect, liquid back-mixing, etc., and achieve height reduction , Reduce the spacing between the trays, and the effect of uniform gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

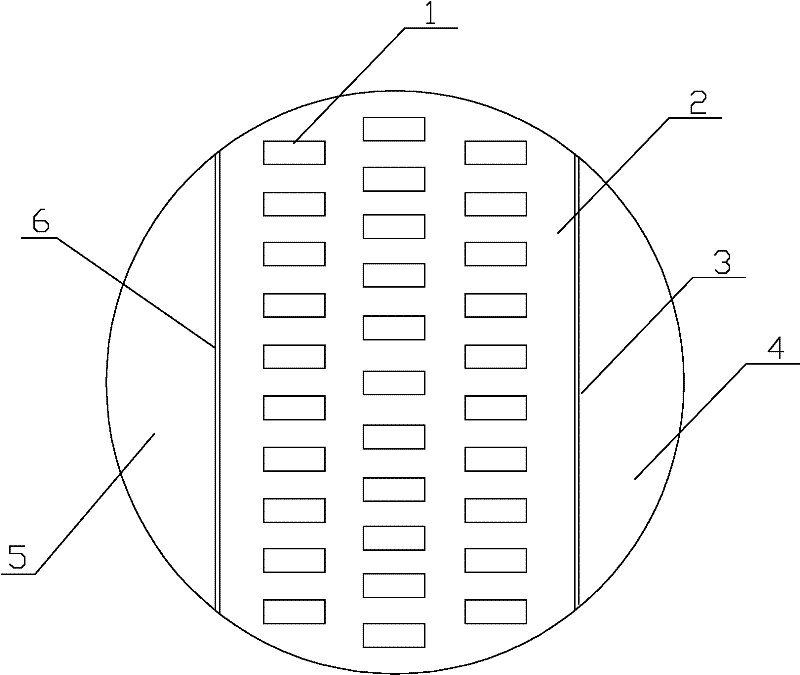

Embodiment 1

[0036] The microbubble mass transfer tray consists of a tray 2, a microbubble mass transfer valve body 7 arranged on the tray 2, a valve hole 1, and a liquid-receiving structure (downcomer 4, liquid-receiving tray 5, inlet weir 6 and Outlet weir 3) composition, wherein the tray structure such as figure 1 As shown, the relative position of the tray and the valve body is as follows Figure 4 As shown, the valve body structure is as Figure 9 shown. Among them, the valve body needs to be able to completely cover the valve hole, the cross-sectional area of the microbubble mass transfer valve body is greater than the valve hole area, and the upper surface of the valve body is higher than the upper surface of the tray, and the height difference = the height of the valve body. The microbubble mass transfer valve body is made of ceramics with a pore volume fraction of 90% and a pore diameter of 0.1 mm. Its structure is a sponge-like porous structure. The valve body 7 is rectangula...

Embodiment 2

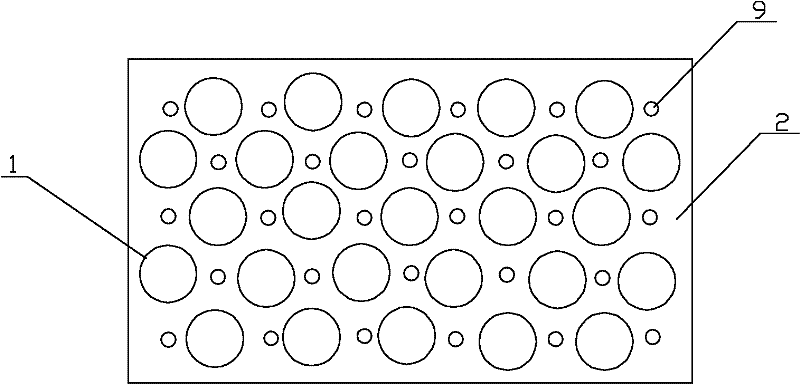

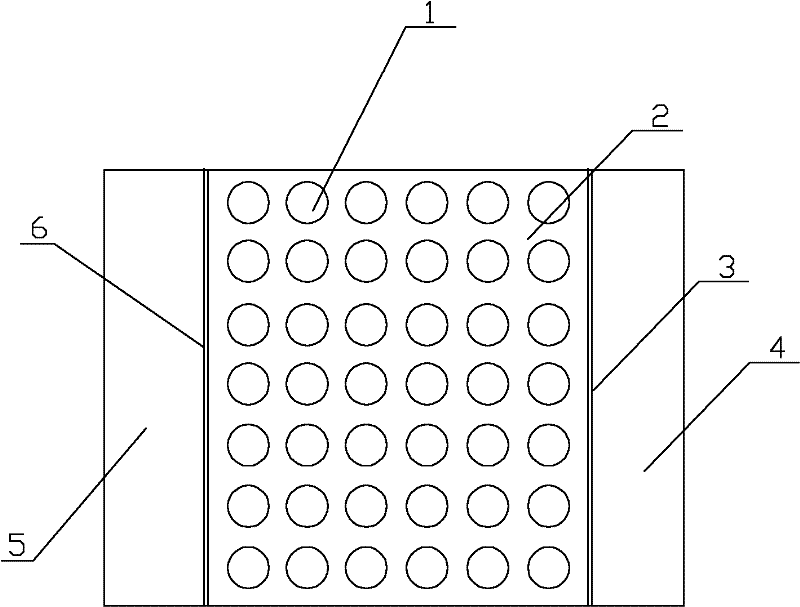

[0039] The microbubble mass transfer tray is composed of a tray 2, a microbubble mass transfer valve body 7 arranged on the tray 2, a valve hole 1, and a shower hole 9, wherein the tray structure figure 2 As shown, the relative position of the tray and the valve body is as follows Figure 5 As shown, the valve body structure is as Figure 10shown. Among them, the valve body needs to be able to completely cover the valve hole, the cross-sectional area of the microbubble mass transfer valve body is greater than the valve hole area, and the upper surface of the valve body is higher than the upper surface of the tray, and the height difference is less than the height of the valve body. The microbubble mass transfer valve body with a pore volume fraction of 50-90% and a pore diameter of 0.1-5mm is made of silicon carbide, and its structure is an irregular porous structure. The valve body 7 is tightly connected to the tray by bonding / welding / inlaying, and the valve holes are st...

Embodiment 3

[0042] The microbubble mass transfer tray is composed of a tray 2, a microbubble mass transfer valve body 7 arranged on the tray 2, a valve hole 1, and a shower hole 9, wherein the tray structure figure 2 As shown, the relative position of the tray and the valve body is as follows Figure 6 As shown, the valve body structure is as Figure 10 shown. Wherein, the valve body needs to be able to completely cover the valve hole, the cross-sectional area of the microbubble mass transfer valve body is greater than or equal to the valve hole area, and the height difference between the upper surface of the valve body and the upper surface of the tray = 0. A microbubble solid valve with a pore volume fraction of 50% and a pore diameter of 5 mm is made of resin. Its structure is a bundle-shaped porous structure. The valve body 7 is circular and is closely connected to the tray by bonding / welding / inlaying. , The valve holes are staggered.

[0043] When the tray is working, the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com