Tank top installing and welding process of single-coating double-wall low temperature storage tank

A technology for low-temperature storage tanks and tank tops, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., to achieve the effects of high construction efficiency, simplified construction procedures, and safe construction work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] This embodiment is for a 30,000 m 3 Welding process for the roof of ethylene single-contained double-wall cryogenic storage tanks. It mainly includes the following steps:

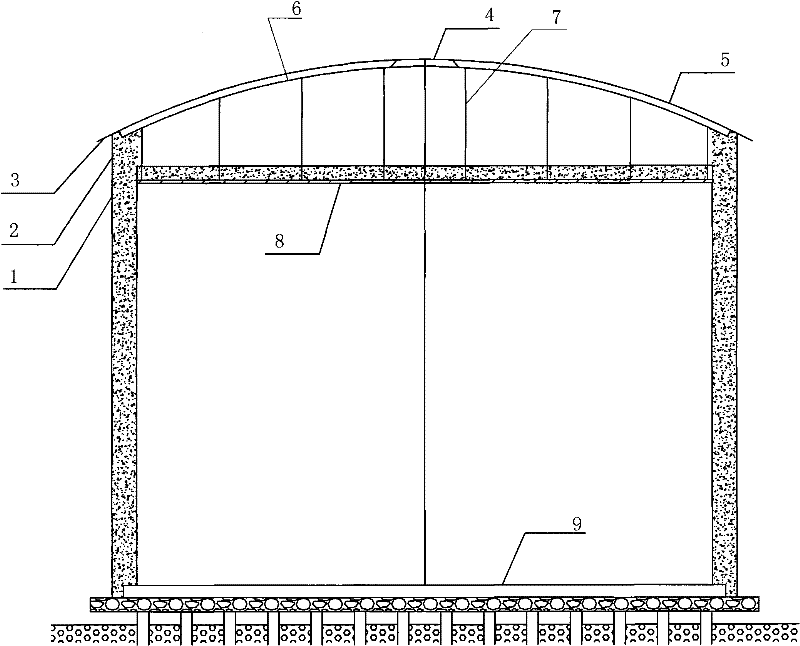

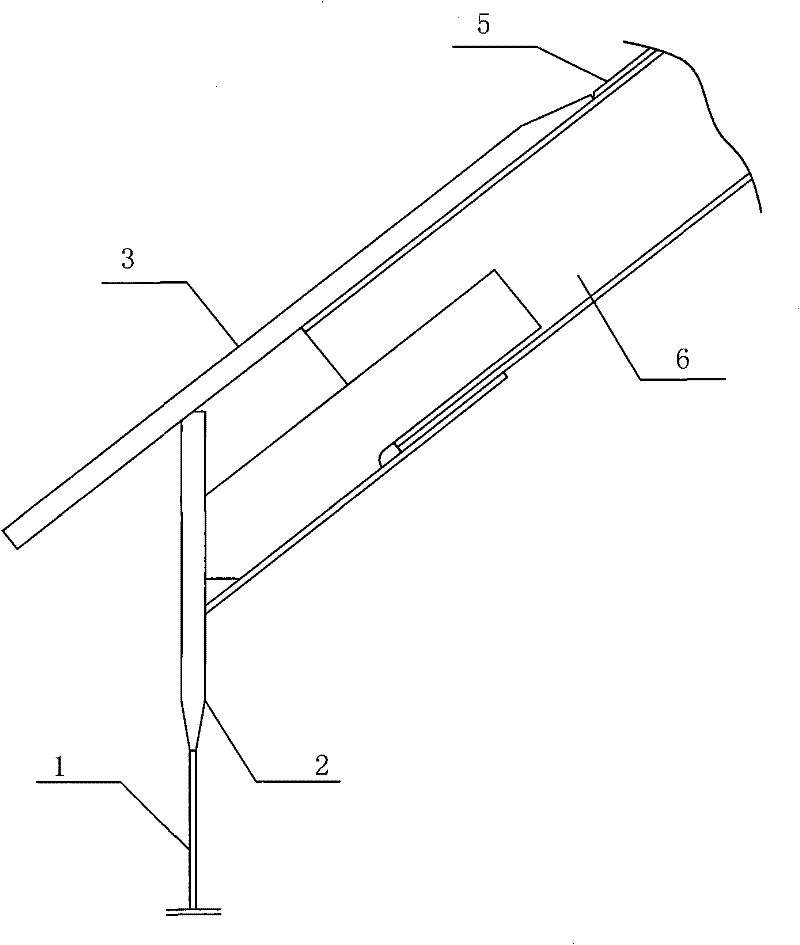

[0036] like figure 1 As shown, after the temporary support pier of the outer tank wall of the single containment double-wall suspended ceiling cryogenic storage tank is installed, the pressure bearing rod 2 is welded on the temporary support pier.

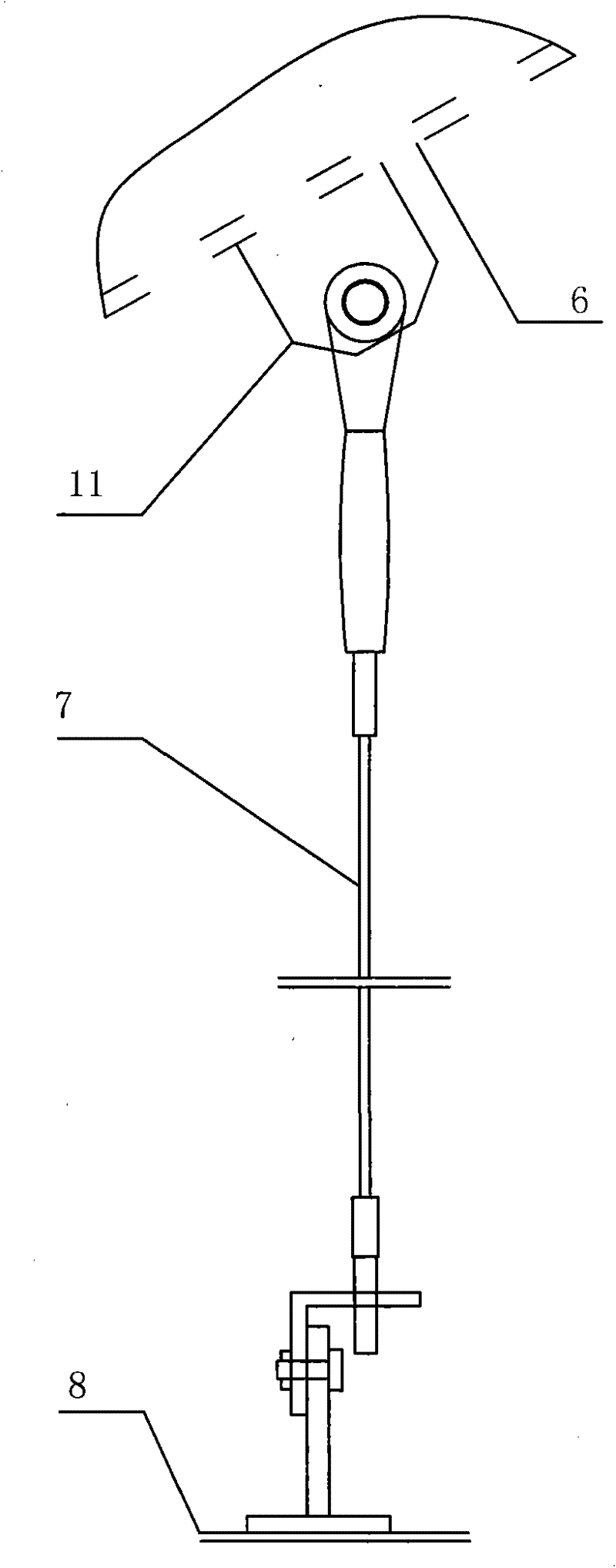

[0037] like figure 2 As shown, after the 9 sets of welding on the bottom of the tank and the welding of 2 sets of pressure rods are completed, the full scaffolding in the tank is built according to the radian of the outer tank roof. The height of the full scaffolding is the net height of the hemispherical outer tank roof. Each arc-shaped H-shaped steel 6 is symmetrically welded on the pressure-bearing rod 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com