Method for preparing composite coagulant used for treating slightly polluted raw water

A coagulant and micro-pollution technology, which is applied in the fields of adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

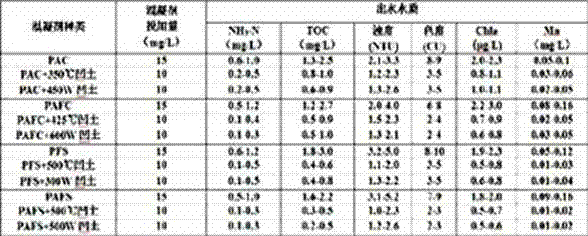

Examples

Embodiment 1

[0022] Embodiment 1: prepare coagulant according to the following steps:

[0023] Attapulgite raw ore is ground into powder and passed through a 300-mesh sieve to obtain attapulgite powder; attapulgite powder is roasted at a temperature of 350°C for 5 hours to obtain modified attapulgite; modified attapulgite is polymerized with 1 wt% inorganic coagulant Aluminum chloride (PAC) is mixed in an aqueous solution, stirred to disperse evenly, dried, and ground to obtain a finished product.

Embodiment 2

[0024] Embodiment 2: prepare coagulant according to the following steps:

[0025] Attapulgite raw ore is ground into powder and passed through a 200-mesh sieve to obtain attapulgite powder; attapulgite powder is roasted at a temperature of 425°C for 3 hours to obtain modified attapulgite; modified attapulgite and its weight of 10wt% inorganic coagulant are polymerized Aluminum ferric chloride (PAFC) is mixed in the aqueous solution, stirred to make it evenly dispersed, dried, and ground to obtain the finished product.

Embodiment 3

[0026] Embodiment 3: prepare coagulant according to the following steps:

[0027] Attapulgite raw ore is ground into powder and passed through a 100-mesh sieve to obtain attapulgite powder; attapulgite powder is roasted at a temperature of 500°C for 1 hour to obtain modified attapulgite; modified attapulgite is polymerized with 20wt% inorganic coagulant Ferric sulfate (PFS) is mixed in aqueous solution, stirred to disperse evenly, dried, and ground to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com