Chemical amplified high-resolution silicon-containing I-ray ultraviolet photoresist and forming resin thereof

A film-forming resin and chemical technology, applied in the field of ultraviolet photoresist, can solve the problem that the resolution of photoresist cannot be further broken through

Inactive Publication Date: 2011-02-16

昆山西迪光电材料有限公司

View PDF4 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to improve the resolution of UV photoresist, people have made a lot of improvements to phenolic resin resin and photosensitizer, and its resolution can reach the range of 0.8-0.5 μm, but the existing technology can no longer break through the resolution of photoresist. Rate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 12

[0065] Embodiments 1 to 12: A chemically amplified high-resolution silicon-containing I-line ultraviolet photoresist and its film-forming resin

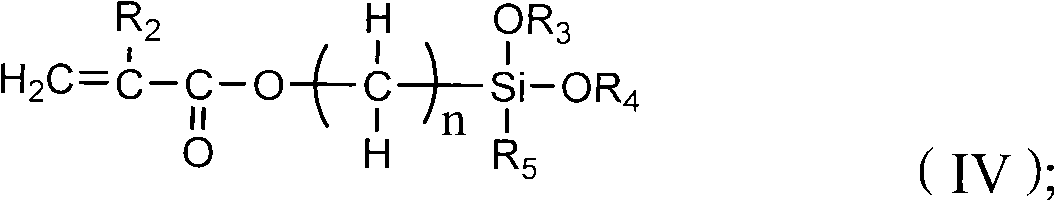

[0066] 1. The comonomers of silicon-containing copolymer film-forming resins are as follows

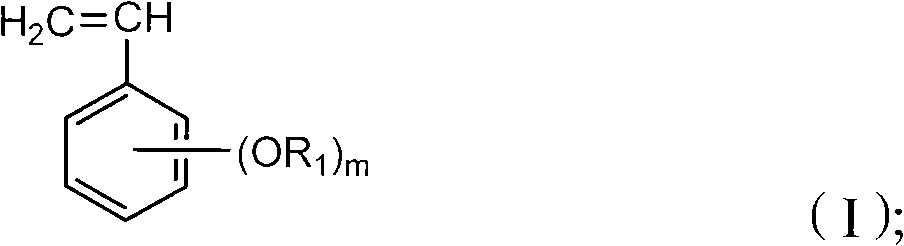

[0067] (1), substituted styrene

Embodiment 1

[0068] Embodiment one: p-Acetoxystyrene

Embodiment 2

[0069] Embodiment two: p-Acetoxystyrene

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a silicon-containing copolymer forming resin which is prepared by carrying out copolymerization reaction on a comonomer in a solvent in the presence of radical initiator, and is characterized in that the molecular weight of the forming resin is 4000-100000; the molecular weight distribution is 1.4-2.8; and the comonomer mainly comprises the following components by weight percent: 40-90% of substituted phenylethylene, 0.5-20% of silicon-containing acrylic ester coupling agent and 5-60% of acidsensitivity-containing basic group monomer. In the invention, the silicon-containing acrylic ester coupling agent which can be copolymerized with the forming resin is introduced in a forming resin formula by taking poly (p-hydroxystyrene) as a base to carry out copolymerization, so as to prepare into the new forming resin. Under the action of the silicon-containing acrylic ester coupling agent unit, the new forming resin increases the adhesive property between the photoresist and a silicon wafer, and simultaneously improves the anti-corrosion performance.

Description

technical field [0001] The invention relates to an ultraviolet photoresist, in particular to a silicon-containing copolymer film-forming resin and a chemically amplified positive photoresist prepared by using the film-forming resin for using I-line (365nm) ultraviolet light as an exposure light source. UV photoresist composition. Background technique [0002] Photoresist is a key functional material for photolithography process in large scale integrated circuit industry. Among them, the film-forming resin is an important part of the photoresist, and its chemical and physical properties directly affect the use effect of the photoresist in the large-scale integrated circuit industry. [0003] The traditional ultraviolet (UV) exposure light source is a high-pressure mercury lamp, and its light wavelength is between 600 and 300nm. Its main spectrum includes g-line (436nm), h-line (405nm) and I-line (365nm). In the photolithography process, the resolution is inversely proportio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F220/28C08F212/14C08F212/08G03F7/075C08F220/18

Inventor 冉瑞成沈吉

Owner 昆山西迪光电材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com