Drying process for humidifying coals by using coke oven flue gas and device

A technology of coke oven flue gas and drying process, which is applied in coke oven and petroleum industry to achieve the effects of easy adjustment, equipment size reduction and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

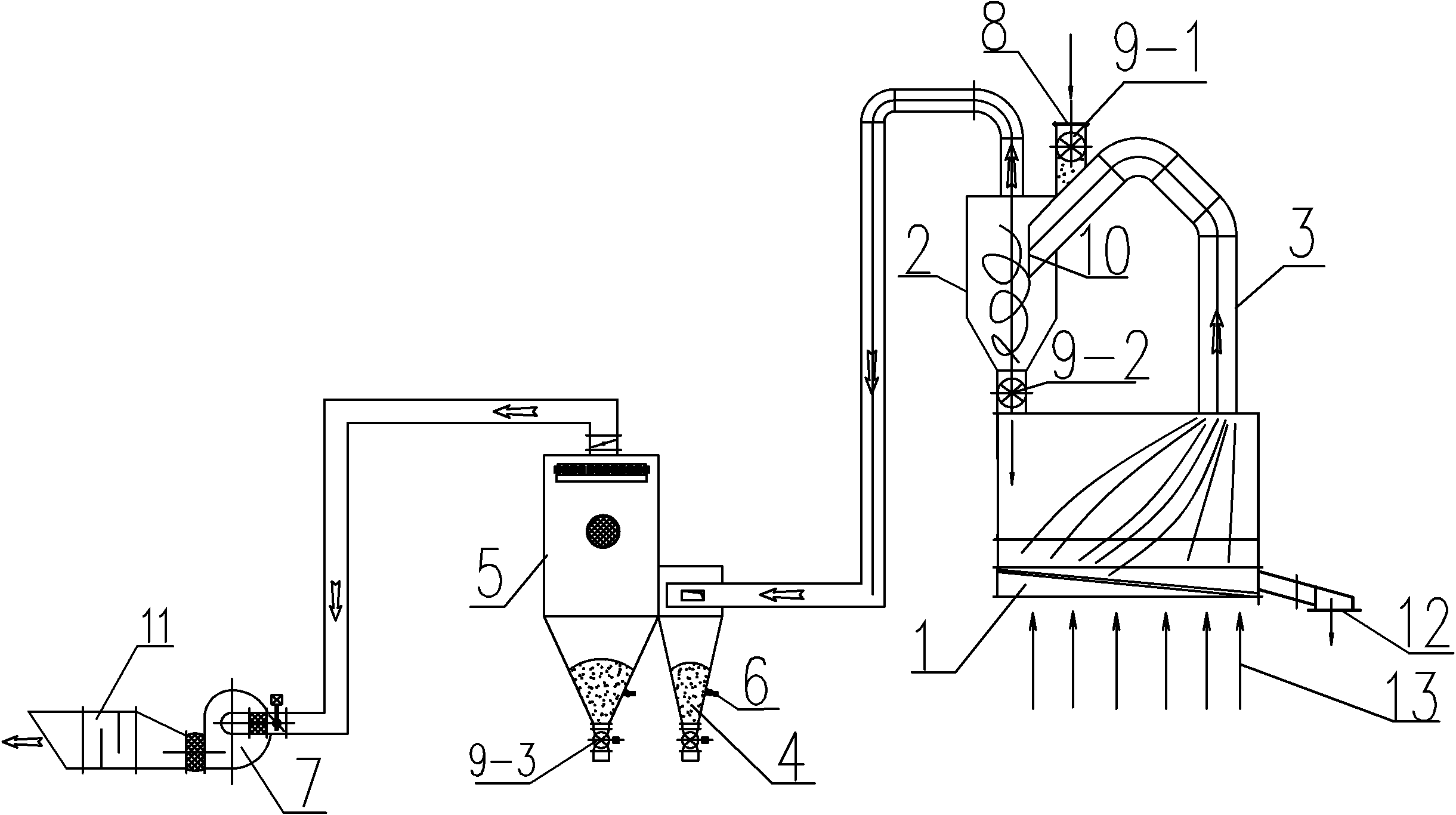

[0024] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] See figure 1 , a drying process for coal humidity adjustment using coke oven flue gas. This process uses the combination of cyclone separator 2 and vibrating fluidized bed 1 to conduct secondary heat exchange between flue gas and coal material, making full use of the coke oven The heat of the flue gas. The specific process is as follows: the coal material enters from the raw coal inlet 8, enters the cyclone separator 2 through the closed format feed valve 9-1, and enters the vibrating fluidized bed 1 through the interior of the cyclone separator 2. Under the action of the blower 7, unsaturated coke oven flue gas at 200-400°C enters the vibrating fluidized bed 1 from the coke oven flue gas inlet 13 to carry out humidity control and drying of the coal material, and the coke oven in the vibrating fluidized bed 1 After sufficient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com