Prefabricated assembled reinforced concrete rectangular inspection shaft chamber

A technology of reinforced concrete and prefabricated assembly, which is applied in the field of reinforced concrete pipes, which can solve the problems of poor durability, high production cost, and low construction level, and achieve the effects of reliable and simple connection, reduced manufacturing cost, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

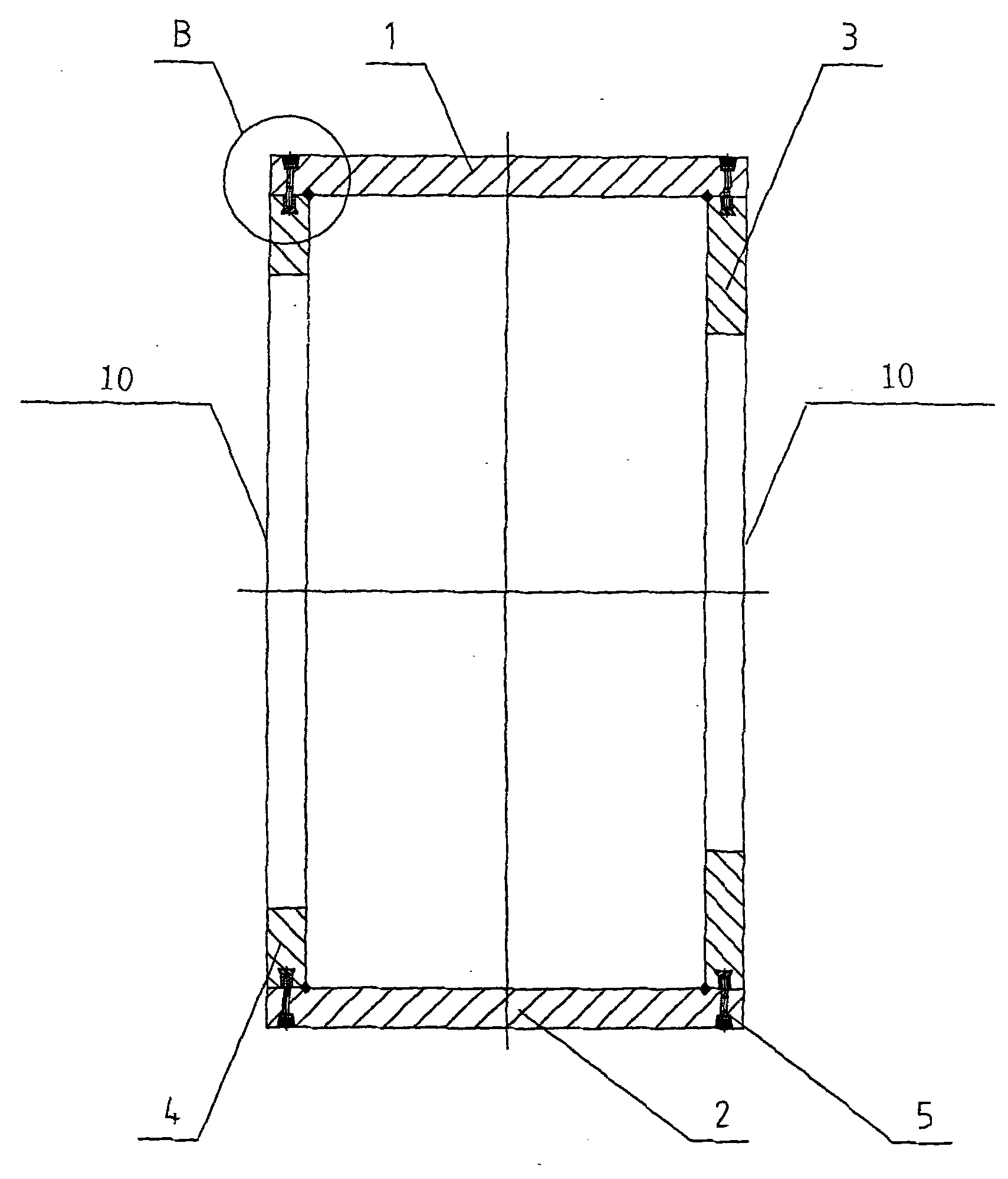

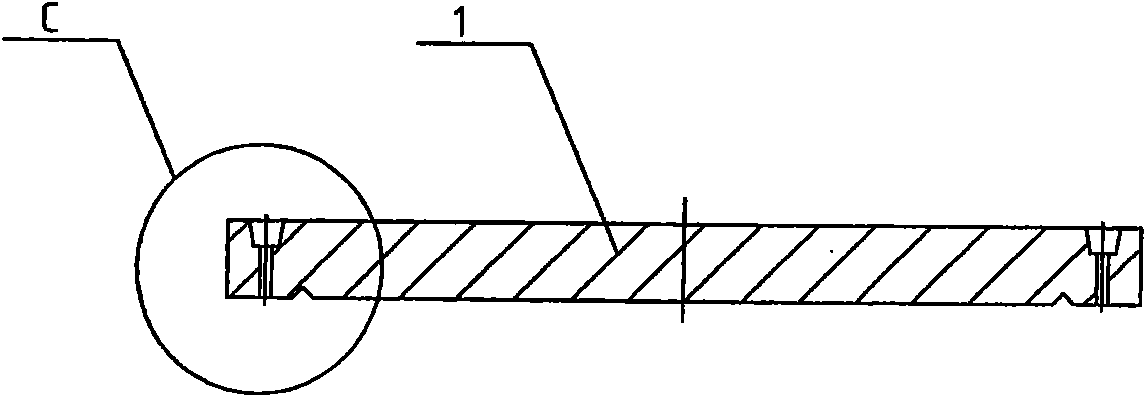

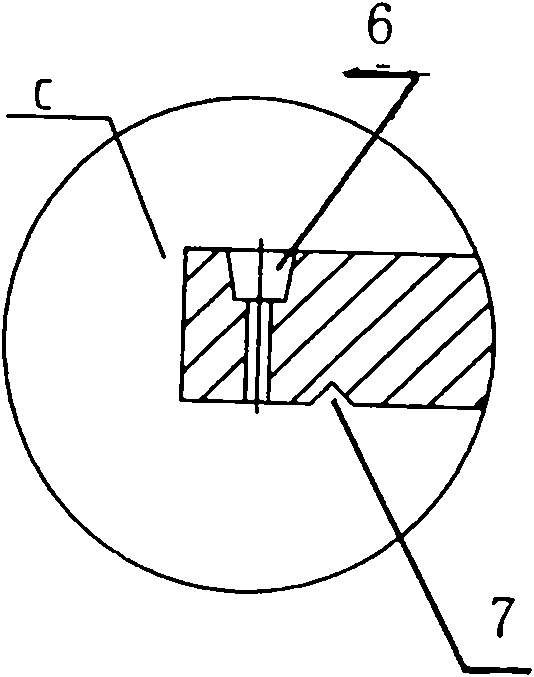

[0017] As shown in the figure: a prefabricated assembled reinforced concrete rectangular inspection well chamber, composed of four wall panels assembled by bolts 5 to form a rectangular inspection well chamber with a cross-section. Two short wall panels 1 and 2 of the above four wall panels are provided with bolt connection holes 6 and "V"-shaped sealing grooves 7, and the other two long wall panels 3 and 4 are provided with anchor nuts 8 and figure-eight sealing grooves. 9 and the branch pipe connecting hole 10, two branch pipes 11, 12 are respectively installed on the inspection well chamber through the branch pipe connecting hole. The long wall boards and the short wall boards are put together to form a square groove-shaped sealing material groove, and an anti-leakage pad 13 is arranged between the wall boards.

[0018] The invention adopts the method of block production, and one platform model can produce all specifications of the wall panels of the inspection well chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com