Hybrid magnetic bearing of rotor inside vertical coil and assembled structure thereof

A hybrid magnetic bearing and vertical coil technology, applied in the directions of magnetic bearings, bearings, shafts and bearings, can solve the problems of difficulty, complex structure, increase the power consumption of the drive motor, etc., and achieve the design structure simplification, eddy current loss and blocking torque. The effect of reducing the magnetic circuit coupling effect is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

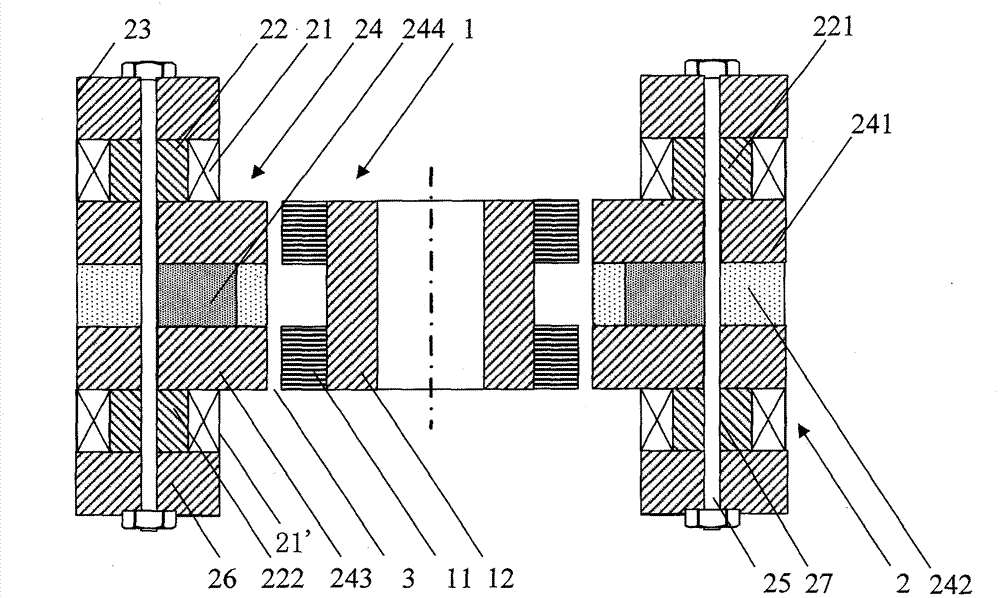

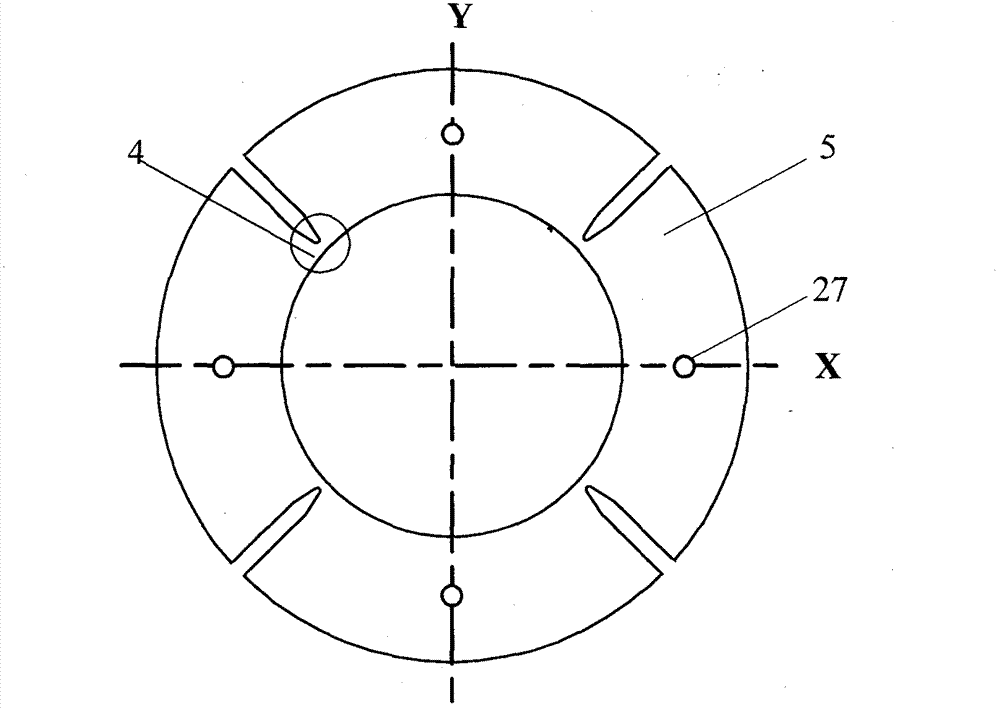

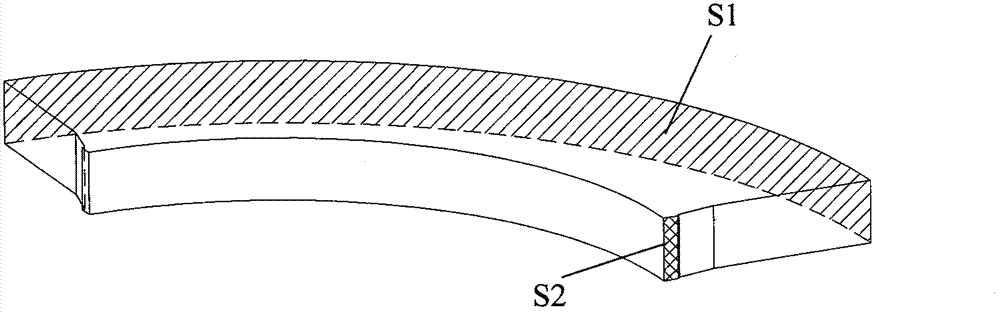

[0066] see Figure 1-Figure 3 , This embodiment of the present invention is made up of rotor 1 and stator 2 two major parts such as above-mentioned scheme. The rotor 1 is installed inside the stator 2 to form an inner rotor. The rotor 1 is composed of a rotor core 11 and an inner magnetically permeable ring 12 , wherein the rotor core 11 is coaxially sleeved on the outside of the inner magnetically permeable ring 12 . The rotor core 11 of the rotor 1 is made of a thin-plate soft magnetic material with good magnetic permeability, such as electrical silicon steel plate, which is stamped and stacked; The cover plate 23, the stator plate 24, four connecting rods 25 and the lower magnetically conductive cover plate 26 are composed of the upper magnetically conductive cover plate 23, the coil core 22, the stator plate 24, and the lower magnetically conductive cover plate 26 in sequence. connected into a whole. The stator disk 24 is composed of an upper magnetically conductive pol...

Embodiment 2

[0070] The hybrid magnetic bearing of the present invention can also be constructed in different ways in its combined structure. For example, if Figure 5 As shown, adopt two sets along the axial direction such as figure 1 The basic structure shown can constitute a magnetic bearing with radial four-axis active control and axial passive stability, that is, the present invention can be designed as a combination of multiple basic structures to meet different requirements. For this combined magnetic bearing, a non-magnetic spacer ring 8 can be set between the upper and lower magnetic bearing stators, and a non-magnetic spacer ring 9 can be set between the upper and lower magnetic bearing rotors 1 . Both the spacer ring 8 and the spacer ring 9 are made of non-magnetic aluminum alloy, copper or non-magnetic stainless steel. In this embodiment, as far as the single product of the present invention is concerned, except that the magnetization directions of the permanent magnets in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com