Air tightness detection method of upper pond body on methane pond

An air tightness detection and biogas digester technology, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the increase and deceleration rate of fluid, etc., can solve the problem of long pressure test time period and can not meet the quality inspection of factory manufacturing Accurate and fast requirements, joint surface sealing defects, etc., to achieve the effect of convenient factory production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

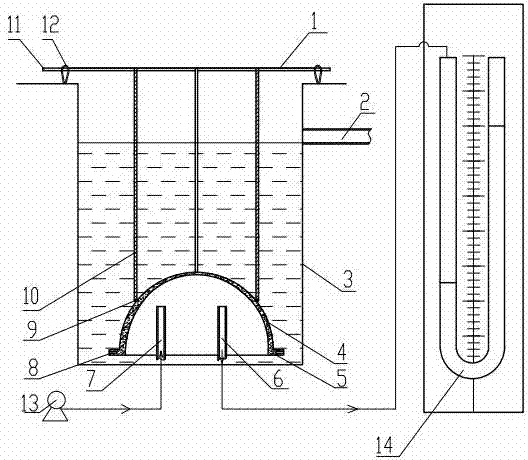

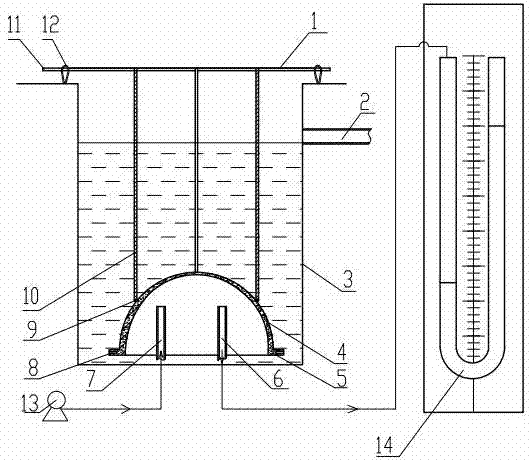

[0021] see figure 1 with figure 2 , the detection method of the present invention is suitable for the biogas digester structure that is manufactured separately from the upper tank body and the lower tank body and assembled on site. The upper pool body is tested for air tightness according to the following method.

[0022] A. Build a test system

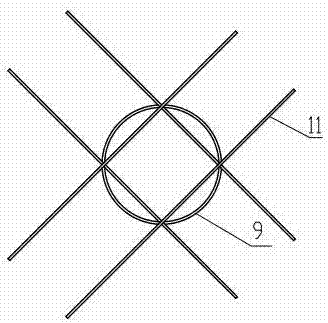

[0023] In the present embodiment, a test tank 3 with a diameter of 3 meters and a depth of 2 meters is dug. The bottom and surrounding walls of the test tank 3 are poured with concrete. 7 and one end of the pressure guide tube 6 extend into the test tank 3, and the other end is respectively connected to the air outlet of the air pump 13 outside the test tank 3 and the U-shaped tube pressure gauge 14 with a water column of 2000mm; set at 1600mm above the bottom wall The overflow pipe 2; the upper edge of the test tank 3 is provided with a collar 11.

[0024] B. Detection process

[0025] ① The upper pool body 4 to be tested is ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com