Method and device for measuring dynamic fracture property of laser shock loading material

A technology of laser shock and measurement method, applied in the direction of measurement device, analysis material, strength characteristics, etc., can solve the problems of large size, not high enough, more material waste, etc., to achieve the effect of improving loading rate and reliable fracture characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

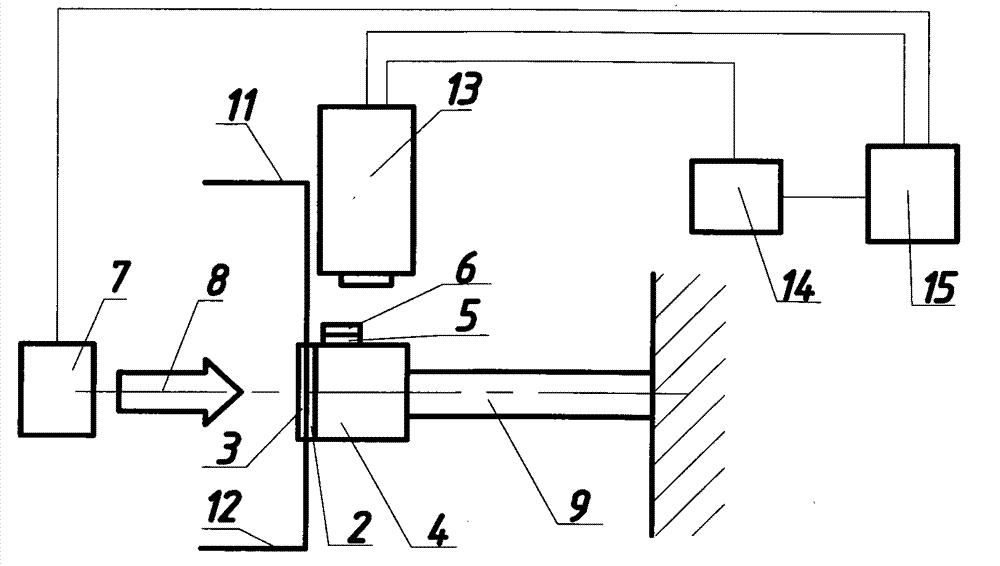

[0029] Feasibility analysis of the device: The size of the three-point bending sample 4 is made according to the provisions of GB / T 21143-2007 (Unified test method for quasi-static fracture toughness of metal materials). According to the definition of stress wave velocity: It can be calculated that most of the stress wave velocities are in the range of 1000-5000m / s. The WZDD-1 multi-spark camera optical system 13 adopts small-sized electric spark light sources arranged in a 4×4 square, and can record 16 dynamic photoelastic images that have gone through a period of time in one operation. The amplitude of the multi-spark camera optical system 13 can be adjusted to 2~80×10 4 frame / second, that is, the minimum time interval is 1.25 microseconds, and the shortest time history of sixteen photos is 20 microseconds. Therefore, it can be photographed that the distance that the stress wave 17 propagates in the three-point bending specimen 4 is 20-100 mm. This distance can be used a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com