3 omega thermal conductivity measurement scheme suitable for metal film material

A technology of metal thin film and metal materials, which is applied in the field of microelectronics, can solve the problems that the suspension bridge structure process cannot be realized, large measurement errors, complex process steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, the present invention will be described more specifically with reference to examples in conjunction with illustrations. The present invention provides preferred embodiments, but should not be construed as being limited to the embodiments set forth herein.

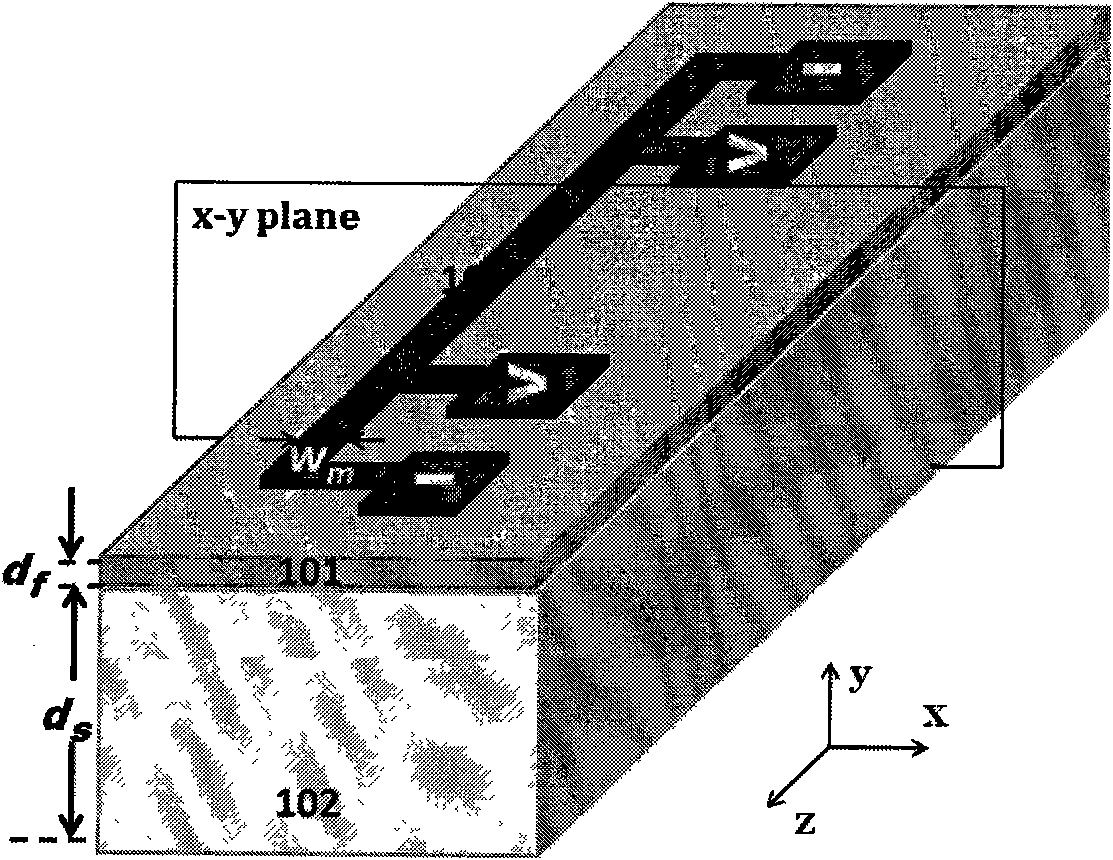

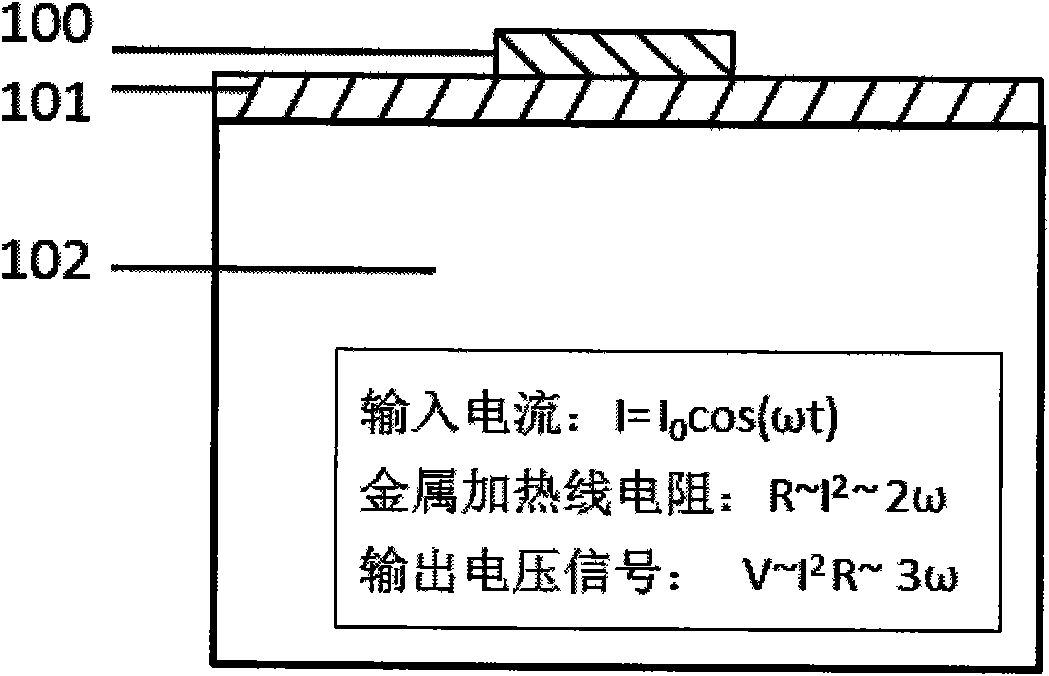

[0043] figure 1 Experimental structure for conventional 3omega thermal conductivity measurements. A nanoscale dielectric thin film is deposited on a silicon substrate, and the metal thin film is patterned on the surface of the dielectric thin film by means of deposition, photolithography steps or nanoimprinting to prepare a narrow-line four-terminal test structure.

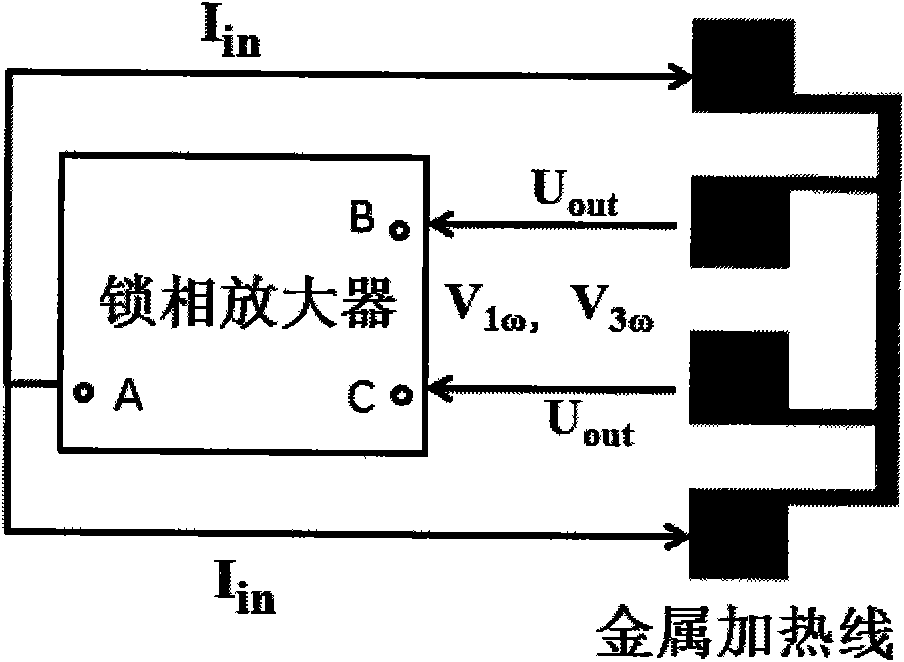

[0044] figure 2 It is the circuit diagram of the 3omega thermal conductivity measurement experimental instrument. In order to measure the 3ω signal at the voltage output end of the metal heating wire, the signal generator inside the lock-in amplifier generates an input AC signal with an angular frequency of ω. According to the working pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com