High-efficiency dielectric lens antenna based on novel open-celled structure

A technology of dielectric lens antenna and Lumberg lens antenna, which is applied to antennas, antenna supports/installation devices, electrical components, etc., can solve the problems of complicated column holes, high cost, and difficult combination of each layer, and can offset the antenna gain. reduce the cost of processing, and facilitate the effect of installation and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

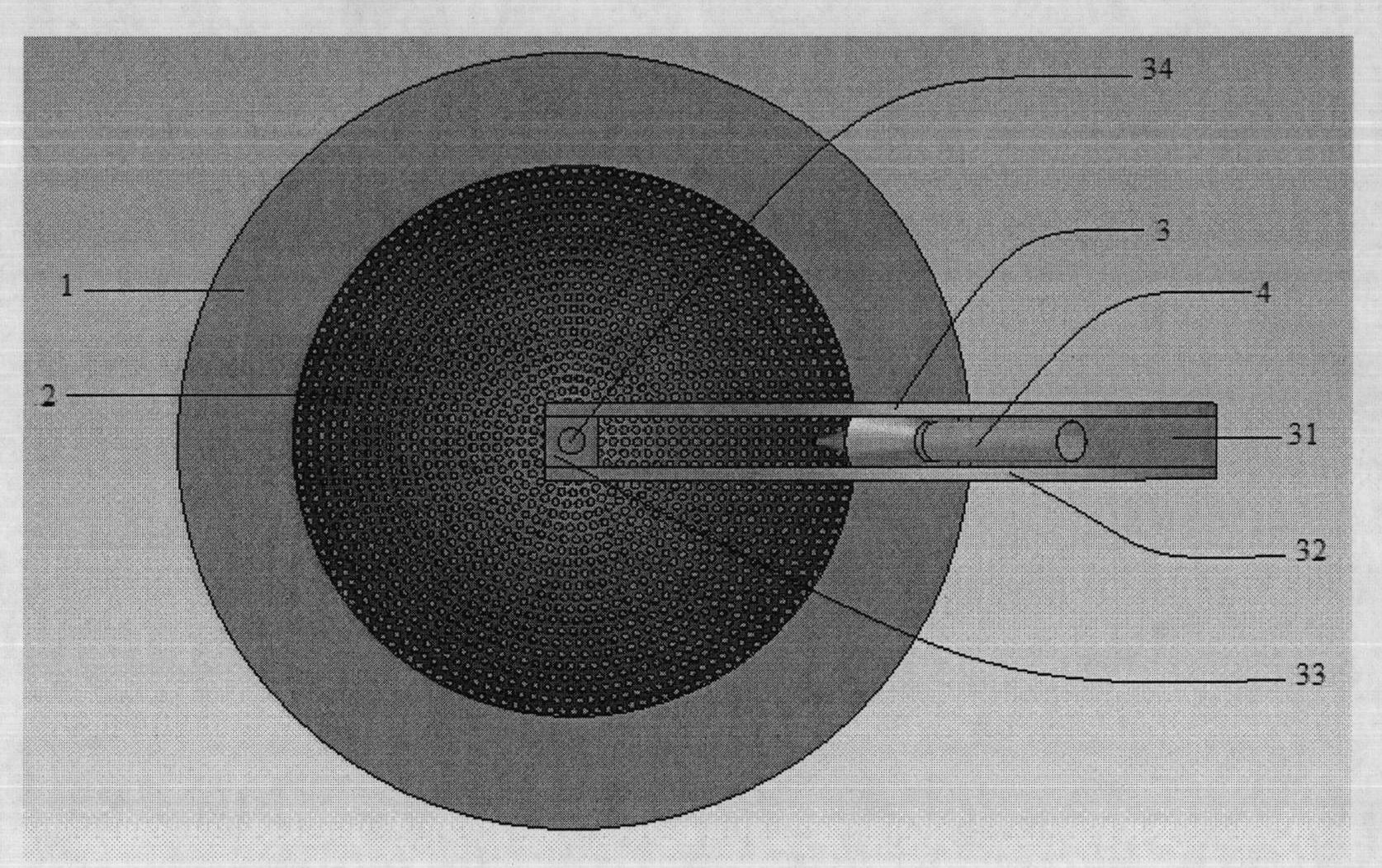

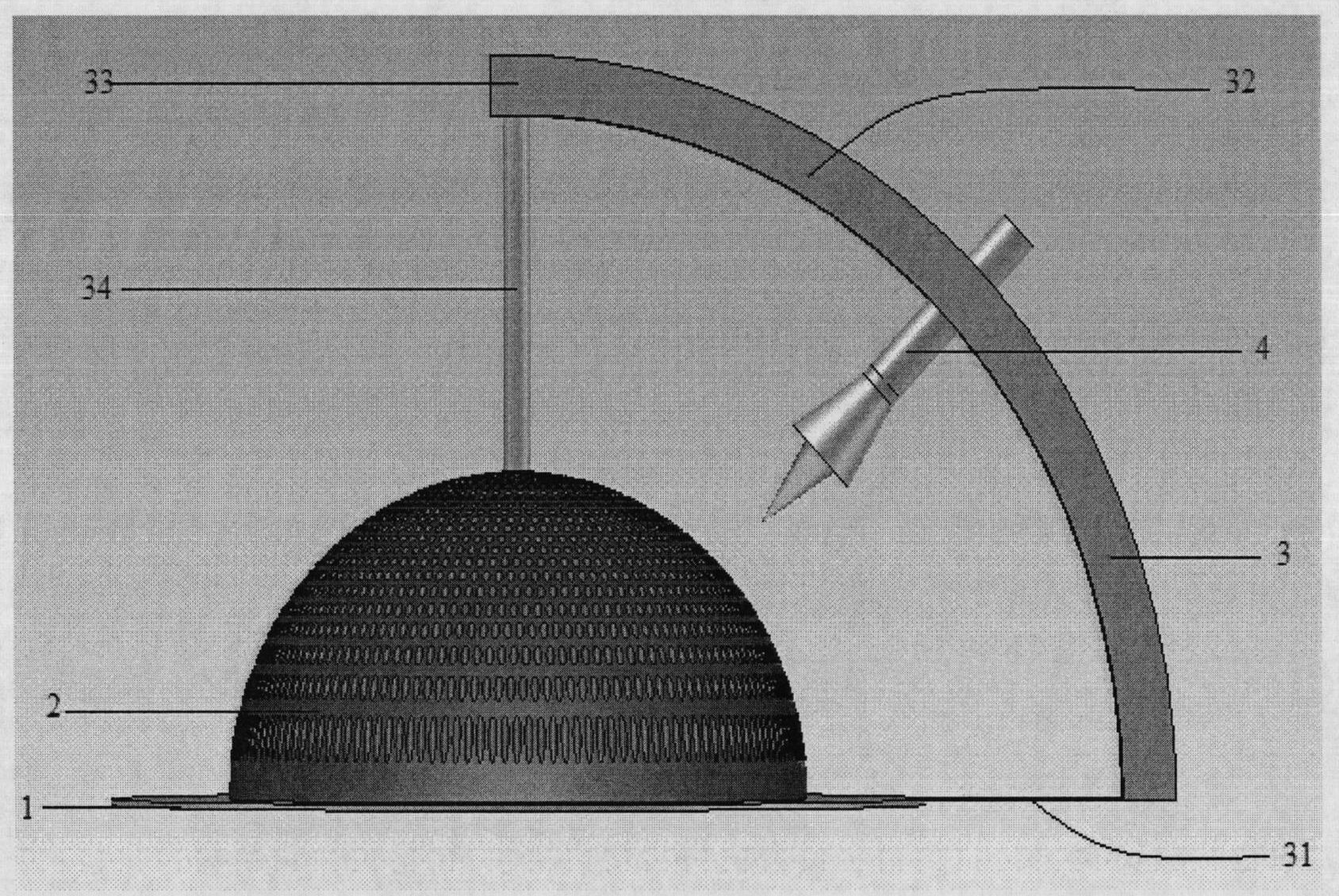

[0024] figure 1 with figure 2 Exemplarily described is a dielectric lens antenna design device with a high efficiency equivalent dielectric constant. According to the illustration, the device mainly includes a metal reflector, a bracket rail, a dielectric lens, and a high-efficiency feed. The metal reflector 1 is made of super duralumin plate, and of course it can also be made of other metal materials such as stainless steel. The metal reflector mainly plays the role of reflecting internal electromagnetic waves and shielding external interference.

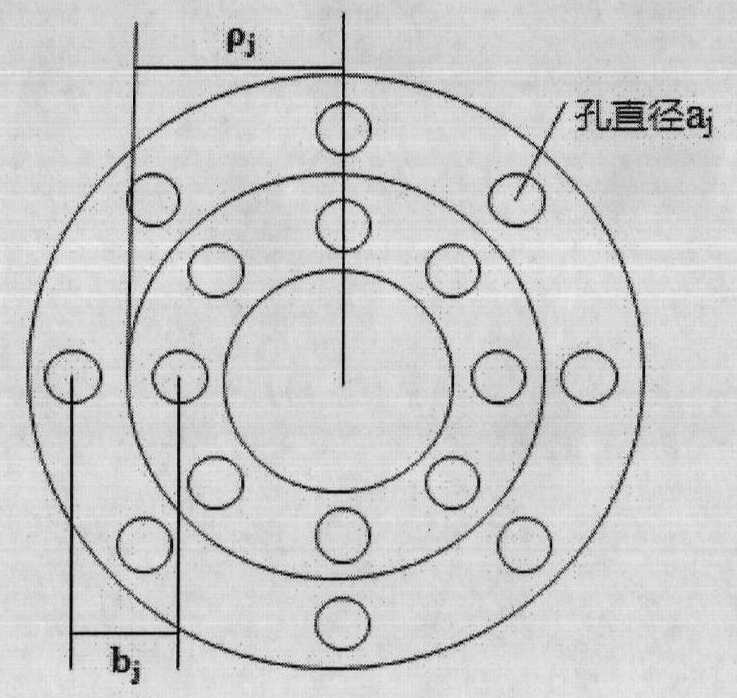

[0025] The dielectric lens part 2 is fixed on the metal reflector 1 by means of the dielectric bracket 3 . In particular, in the present invention, the hole structure of the dielectric lens is designed as a cylindrical hole structure. Specifically, cylindrical holes with a certain regularity and uniform distribution are drilled on a polytetrafluoroethylene with a large dielectric constant a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com