Connection pin and electrical connection

A technology of connecting heads and connecting pins, which is applied to the connection of conductive adhesives, the shape of heating elements, and the device that coats the surface with liquid. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The same reference numbers refer to the same or similar components below.

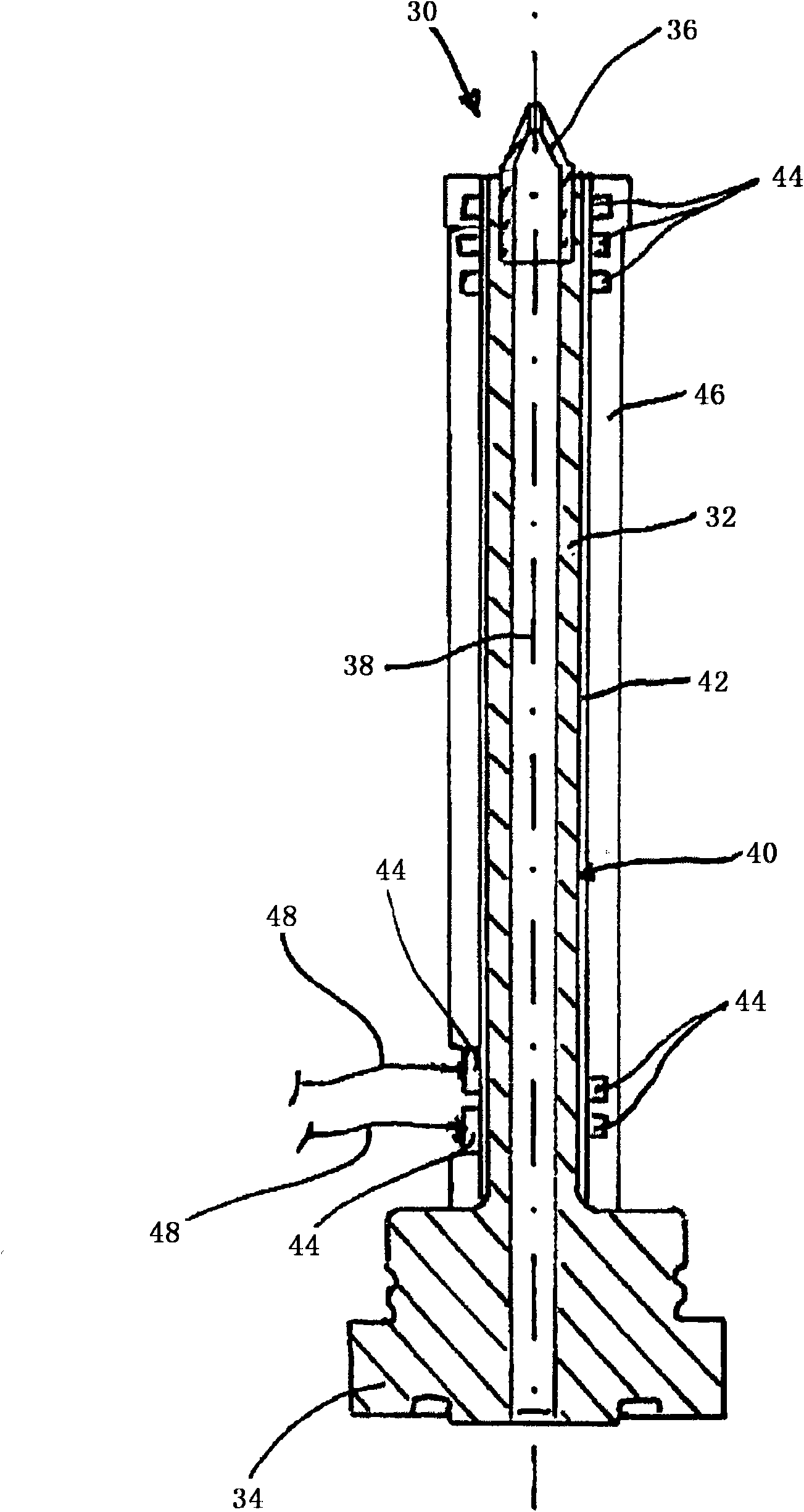

[0032] figure 2 Injection molding nozzle 30 shown in , as a component of an injection molding plant for thermoplastics processing, has a housing (also not shown) for attachment to a (not shown) distributor, overall cylindrical material A tube 32 can be inserted into the housing.

[0033] A seat 34 formed on the end side of the material tube closes flush with the housing and rests sealingly against the distributor. On the end side, a nozzle tip 36 is inserted, preferably screwed, into the axially longitudinally extending material tube 32 , which continues the flow channel 38 formed in the material tube 32 to the (likewise not visible) on the plane of the mold cavity (not shown). With the same operating principle, the nozzle tip 36 can also be formed in one piece with the material tube 32 .

[0034] A ceramic dielectric layer 42 is applied on the periphery of the wall 40 of the material tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com